- [email protected]

- +86-21-63353309

primary crusher and secondary crusher

primary crusher and secondary crusher

Types of Crushing Equipment - Jaw, Cone & Impact

Jaw crushers; Cone crushers; Impact crushers, also known as hammer crushers. Why Choose A Jaw Crusher? It's a

Learn Morehow to install a secondary crusher

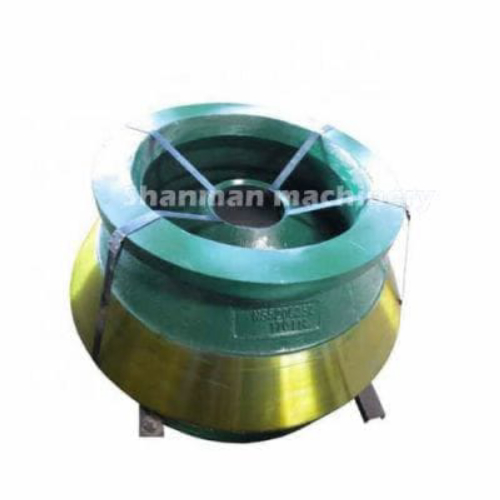

Gyratory crushers. Gyratory crushers are frequently used in the primary crushing stage and a little less often in in the secondary stage. Gyratory crushers have an oscillating shaft. The material is reduced in a crushing cavity, between an external fixed element (bowl liner) and an internal moving element (mantle) mounted on the oscillating

Learn Moreallis chalmers primary girotry crusher specifications

1000 TPH Primary Gyratory Crushing Plant Item #1 - Fuller-Traylor Model 42-70 Type TCB Gyratory Crusher with cast steel two piece mainframe, 400 - 4,000 volt electric motor, direct shaft drive, hydraulic $145,000.

Learn MoreP&Q University Lesson 7- Crushing & Secondary Breaking

Secondary impact crushers and cone crushers are used to further process primary-crushed aggregate, and can be operated with or without attached

Learn Moreprimary and secondary impact crushers

primary and secondary impact crushers Primary Crusher Selection & Design Crushing for particle shape Aggregates Manager Impact Crushers Equipment For Sale or Lease Frontline. Prim

Learn Moreused for primary stone crusher

Primary Crusher And Secondary Crusher. HTTPS. Primary jaw crusher uses the squeezing and bending action of the two jaw plates to complete the work.

Learn MoreCrusher Selection And Types of Crusher - Engineering Intro

Now a secondary crusher comes into action and further reduces the size. In secondary crusher some sizes of stones may pass directly from sieve

Learn MorePrimary crusher, Primary crushing and screening plant - All

Weight: 17,715, 24,500 kg. Motor power: 200, 250 kW. UĞURMAK CDK Series Primary Impact Crushers have a design that allows the rotor, two pendulum systems and wear plates to work in harmony. Thanks to this compatibility, it offers high performance and low

Learn MoreSecondary Crushing Equipment - Mineral Processing & Metallurgy

Three factors are of prime importance in selecting the size and type of the secondary crusher, or crushers: capacity; size of feed, size of product. You add to these the item of product characteristic, which embraces shape characteristic, and gradation. These are not always important, but they are sometimes very much so. Capacity of Secondary Stage

Learn Morecrusher installation in primary sequence secondary and tertiary

Crusher installation in primary sequence Primary stone crusher,secondary crusher,tertiary crusher pew jaw crusher this series of jaw crusher crushing compression strength not higher than 280mpa ore, rock, slag, etc, were broken. Obtener precio. Aggregate Crusher Plant Machine DM 55 Mobile Tertiary .

Learn MoreFrantoio ad impatto FABO PDK-90 SERIES 100-150 TPH PRIMARY IMPACT CRUSHER

Annuncio di vendita frantoio ad impatto FABO PDK-90 SERIES 100-150 TPH PRIMARY IMPACT CRUSHER nuovo dalla Turchia. Frantoio ad urto. Frantoio a urto. Prezzo: prezzo su richiesta. Anno di costruzione: 2021. PM24941

Learn MoreCrusher; Crushing; and Classification Equipment - SlideShare

Mineral Processing: Crusher and Crushing; Secondary and Tertiary Crushing Circuits; Types of Crusher; Types of Crushing; Types of Jaw Crushers;

Learn Moreprimary and secondary crusher | bushing of ball mills picture

NPK's Primary/Secondary Crushers are designed to effectively handle any primary and/or secondary demolition and recycling operation. NPK crushers easily cut Simplifying the crushing process - Pit & Quarry : Pit & Quarry. May 10, · 1. Primary crushing. As the first stage in a crushing circuit, primary crushing reduces material to a

Learn Morewhat's the function of a primary and secondary crusher

Know More ; different between primary and secondary crusher - Know More The choice between compression and impact crushing involves some , and are often run as primary or secondary crushers, occasionally tertiary What is the difference between primary and secondary deviance , Primary deviance is a behavior in which the participant does not react negatively to perceived misbehavior

Learn MorePrimary Crushing - Mineral Processing & Metallurgy

A crusher of these dimensions will break 40 tons per hour to 2½-in. size with a power consumption of 30 h.p. On the other hand, a 14-in. gyratory crusher, working as it should at full capacity, will crush 100 tons per hour to the same size with a power consumption of 70 h.p. ; at 40 tons per hour, it would still require about 50 h.p.

Learn MorePrimary And Secondary Crushing Crushers

Crushers and Their Types IspatGuru Apr 03, The primary crusher receives material directly from run of mine ROM after blasting and produces the first reduction in size. The output of the primary crusher is fed to a secondary crusher, which further reduces the

Learn MoreCrusher Primary Secondary | Crusher Mills, Cone Crusher, Jaw Crushers

The Jaw crusher is used for Primary crushers and Secondary crushers for crushing all kinds of Primary & secondary crusher in limestone processing plant Limestone is a sedimentary rock composed largely of the mineral calcite (calcium carbonate: CaCO3). Limestone is the major raw material to produce cement, limestone

Learn MorePrimary And Secondary Crushers

PRIMARY/SECONDARY CRUSHERS Specifications Model Backhoe/ Weight Max Jaw Jaw Cycle Oil Operating Max Excavator Opening Width Time Flow Pressure Crushing Jaw Crushers - TRIO Engineered Products. TRIO offers a wide range of sizes of primary and secondary jaw crushers. They incorporate steeply aligned toggle seats for

Learn MoreSecondary Crushing Equipment - 911 Metallurgist

The simplest form of secondary crushing stage involves a single crusher, taking its feed by gravity flow direct from the primary with no

Learn MoreCrusher - Wikipedia

A crusher is a machine designed to reduce large rocks into smaller rocks, gravel, with primary and secondary crushers handling coarse materials,

Learn MoreDifferent types of crushing equipments - Constro Facilitator

5/6 · Types of crusher depend on the feeding method. These are- Primary crusher, Secondary crusher and Tertiary crusher. The primary crusher is only for the breaking of

Learn More