- [email protected]

- +86-21-63353309

cone & mantle in crusher

cone & mantle in crusher

cone and mantle components of stone crusher machine GP11F CURVE G11

Jaw Crushers. Jaw Models & Literature; Portable Jaw Plants. LJ3055 Portable Jaw Crushing Plant; Mobile Track Plants. 1200j Electric Track-Mounted Jaw Crusher; cone and mantle components of stone crusher machine GP11F CURVE G11 types of stone crusher Quality, Versatility, Reliability for Thousands Less

Learn MoreCone Mantle - Cone Crusher Parts Manufacturer from Jaipur - Jhalani Ispat

Manufacturer of Cone Mantle - Cone Crusher Parts offered by Jhalani Ispat Private Limited, Jaipur, Rajasthan. Jhalani Ispat Private Limited. V. K. I. Area, Jaipur, Rajasthan. GST No. 08AAACJ4607P1Z9. TrustSEAL Verified. Call 08048601115 81% Response Rate. SEND EMAIL.

Learn MoreCone Crusher Replacement Wear Parts - Columbia Steel Casting Co Inc

OEM liners are based on average conditions, and few cone crushers work under "average" conditions, which is why we have so many options available. Matching sets for better production Our engineers work to improve production throughout the liner life, and to arrive at even wear ratios between mantle and liner to minimize discard weight.

Learn MoreCrusher Concave Liners and Mantle Wear - Mineral Processing & Metallurgy

Crusher Concave Liners and Mantle Wear Previous Next As the Crusher Concave Liners and Mantle Wear out there is a period when the crusher won't be as efficient as it could be. This can be a very frustrating period for the operators. Since the throughput drops and operators have to work harder, usually doing the same thing over and over again.

Learn MoreMethod for securing a gyratory crusher mantle

5080294, Gyratory mantle liner assembly, 1992-01-14, Dean, 241/294. 4895311, Supporting structure for the crushing head of a cone crusher

Learn Morehow to change the cone crusher mantle?|News-CFTC

The cone crusher mantle is one of the parts of the cone crusher. If the operation is improper or the material hardness is too large, it is easy to cause damage to the part.For cone crusher, some internal parts are easy to be worn. When the wear is serious, it needs to be replaced to restore the working performance of the equipment.

Learn MoreCone crusher tooling Lock nut / bolt tightening tool

In the past, mantle changes for a cone crusher have been a safety concern and introduced risk to plant operation when not performed correctly.

Learn Moreproduct information mantel is designed to protect the cone crusher

cone and mantle for crusher plant You Can Buy Various High Quality Cone Crusher Mantle Products from Global Product information of Cone Crusher Mantle: Mantel is designed to protect the Chat Now; Used Crusher Mantle If you want to get more detailed product information and prices, Mantel is designed to protect the Cone crusher,

Learn MoreChina Stone Cone Crusher Mantle Parts Apply to

Stone Cone Crusher Mantle Parts Apply to cone crusher · Product Name: Cone Crusher wear parts/ concave/bowl liner/cone liners/high

Learn MoreMantle For Cone Crusher - Jaw Crusher Wear Parts, Cone Crusher Wear

The mining equipments include jaw crusher, impact crusher, cone crusher, sand making machine, vibrating screen, vibrating feeder, sand washing machine, belt conveyor, and so on. The wear-resisting castings include jaw plate, toggle plate, hammer, blow bar, liner plate, cone parts and screen mesh.

Learn MoreCone Crusher Basics - Porter Group

The eccentric throw is one of the most important parameters in defining the job that your cone crusher does. The mantle in a cone crusher spins in conical pendulum motion. That means it doesn’t stay in the centre of the chamber – it sweeps around moving closer and further away from the concave. This is what creates the crushing action.

Learn Morecrusher plant mantle and concave

The mantle performs eccentric movements under the concave (also called bowl liner), so squeezing & crushing the material between the cone crusher mantle and concave. In general, a cone crusher runs on V-belts driven by an electric motor or diesel engine. Extensive application of Cone crusher in aggregate and mineral processing industries.

Learn MoreReplacing the liner of a HP cone crusher - Outotec

The HP cone crusher is a very important piece of equipment in a crushing plant. It can operate as a secondary, tertiary or quaternary

Learn MoreCone Crusher Mantle | Crusher Mills, Cone Crusher, Jaw Crushers

Cone Crusher Mantle Diameter-The First Cone Crusher From China Cone crushers come in different sizes depending on desired production output rates. This size also determines the maximum diameter of input material the cone crusher Cone Crusher Jaw Crusher Concrete Batching & Mixing Plant

Learn MoreCrusher - Wikipedia

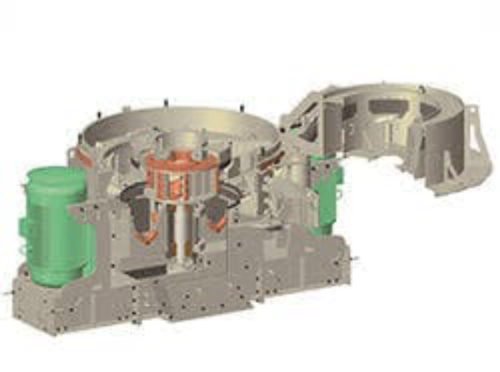

A cone crusher breaks rock by squeezing the rock between an eccentrically gyrating spindle, which is covered by a wear-resistant mantle, and the enclosing concave hopper, covered by a manganese concave or a bowl liner. eccentric shaft, crushing cone, mantle, bowl liner, adjusting device, dust ring, transmission device, bowl-shaped bearing

Learn MoreHigh-Efficiency Cone Crusher ZI Cone Crusher | ANSWERS

The ZI Cone Crusher, launched in as a strategic model for overseas markets, was developed to meet the market demand for high

Learn MoreGP Series™ cone crushers - Outotec

Features. ® GP Series™ cone crushers have been developed to crush feed materials into desired end products efficiently, reliably, and economically. Engineered for all rock types, these machines can be utilized as secondary, tertiary, and quaternary crushers in aggregates production plants and in mining operations.

Learn More12 tips to maximize cone crusher productivity - Outotec

A crusher should be operated above 40% but below 100% rated horsepower in order to maximize cone crusher productivity and to have a proper "loaded bearing alignment". An optimal power range is to operate between 75%-95%. Operating a crusher above 110% rated power can cause premature crusher failure.

Learn MoreA Detailed Overview of Cone Crushers and What You Need to Know

A cone crusher has two sides: an open side and a closed side. As the material crushes, the particles that are small enough to fit through the open side fall through the space between the mantle and the concave. As the mantle gyrates, it creates a narrow point and a wide point.

Learn MoreCone Crusher Mantle - SHANVIM

Cone Crusher Mantle - China Manufacturers, Suppliers, Factory We rely upon strategic thinking, constant modernisation in all segments, technological advances and of course upon our employees that directly participate in our success for Cone Crusher Mantle, Vsi Rotor Parts, Shredder Hammer Bulkbuy, High Mn Jaw Plate, High Chromium Square Bar.

Learn MoreManganese Steel Cone Mantle For Cone Crushers

Manufacturer of Manganese Steel Cone Mantle For Cone Crushers - Puzzolona 22100 Cone Mantle offered by Jhalani Ispat Private Limited, Jaipur, Rajasthan. Jhalani Ispat Private Limited. V. K. I. Area, Jaipur, Rajasthan. GST No. 08AAACJ4607P1Z9. TrustSEAL Verified. Call 08048601115 81% Response Rate.

Learn More