- [email protected]

- +86-21-63353309

construction of jaw crusher

construction of jaw crusher

AIM: CRUSHING AND GRINDING MAHINERY: - DTE Assam

To study the construction, operation and engineering utilities of “Blake jaw Crusher” . into coarse crushers, intermediate crushers and fine grinders.

Learn MoreJaw Crushers by Hewitt Robins International

The Hewitt Robins Jaw Crushers are known for durable construction, high productivity and a greater value for investment. The rugged design provides the Reliability, quality, capacity, and ease of use you can expect with products from Hewitt Robins and the Jaw crushers are designed to help you be more profitable.

Learn MoreCharacteristics and Comparison of Four Types of Jaw Crushers

Mobile jaw crusher: High mobility determines that it is suitable for frequent conversion of crushing sites (like road construction, urban construction waste disposal, etc).Thus, its price is higher than other kinds of jaw crushers. Why choose Fote jaw crusher manufacturer? The various types of jaw crushers designed by Fote are widely used in many fields including heavy-duty mining, cement

Learn MoreJaw Crusher – Residential And Commercial Construction

Jaw crusher can reach the crushing ratio of 4-6 and the shape of final product is even. They are widely applied to crush high hardness, mid hardness and soft rocks and ores such as slags, construction materials, marble, etc. The pressure resistance strength is under 350Mpa, that is, suitable for primary crush. Jaw Crusher can be used in mining

Learn MoreJaw Crusher Working Principle - StudiousGuy

A jaw crusher mainly works on the principle of reciprocating motion exhibited by the moveable jaw of the jaw crusher. The repeated movement of the jaws results

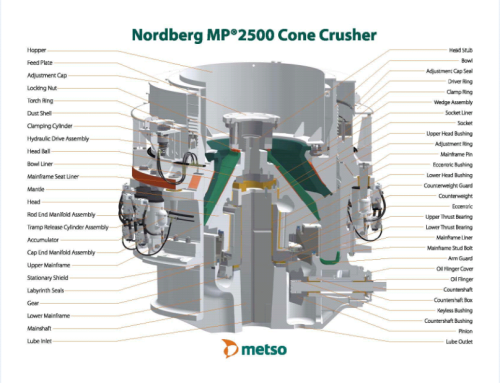

Learn MoreConstruction Of Jaw Crusher Cone Crusher

Construction detail and working of the crusher is as under. The main shaft of the crusher is journaled in the spider bearing and in the eccentric bearing

Learn MoreJaw Crusher - Stone Crushers & Grinding Mills for Mines and Quarry

As the first process of stone crushing line, Jaw Crusher always plays important role. This machine is possess of optimized crushing chamber, heavy eccentric shaft and high manganese steel jaw plate, which takes advantages of high efficiency, strong crushing ability and low investment costs. Applications: Mining, metallurgy, construction

Learn Moreconstruction of jaw crusher | sun hydraulics 740-224

Modular design is adopted to save time and installation cost, and minimize on-site construction work. Blake Jaw Crusher - Mineral Processing & Metallurgy. Jan 15, · In the history of crushers, both chronologically, and by virtue of its standing in the field of heavy-duty crushing, the Blake jaw crusher stands first in the list.

Learn MoreVanguard Jaw Crusher | Construction Equipment

Vanguard Jaw Crusher. March 28, 2014. Redesigned Vanguard jaw crusher has replaceable wear jaw die seats and barrel protector plates parts for an improved life cycle. Jaw die retention wedges hold the jaw die in place, providing easy access to the jaw die and efficient removal and replacement. In addition, the new design contains lifting holes

Learn Moreconstruction of jaw crusher | top grade new coming rice mill machinery

construction of jaw crusher. What is a Jaw Crusher | Advantages, Types, Parts and. Jaw crusher Advantages. Optimize the crushing cavity type to make the stroke at the bottom of the crushing cavity larger, the material handling capacity is stronger, and the crushing efficiency is greatly improved. Modular design is adopted to save time and

Learn MoreConstruction Of A Jaw Crusher-HN Mining Machinery Manufacturer

Construction Jaw Crusher - karishmasteel.com. 20' X 30' Jaw Crusher. jaw crushers are the workhorse of the crushing industry for mining, construction, and demolition recycling. mt. baker mining and metals' jaw crushers are industrial grade, continuous duty machines. they take large pieces of rock, ore, concrete, or other materials, and crush

Learn MoreJaw crusher - SlideShare

Figure 1 Jaw Crusher Design of Jaw Crusher As jaw crusher is designed to impart an impact on the solid particles placed between a fixed and a

Learn MoreWhat is a Jaw Crusher? – MEKA Crushing Equipment

All jaw crushers feature two jaws: one of which is fixed while the other moves. The working principle of jaw crushers is based on the reciprocating movement

Learn MoreJaw crusher with conveyor belt - Faller

The jaw crusher then crushes and mills the stones. Afterwards, a conveyor belt transports the material directly into the stone breaking works (art. 130170). At

Learn MorePDF) Design and Construction of Rock Crushing Machine

Calculation were carried out as per the required length,. shape, allowance and quantity needed to avoid waste of material. Jaw Crusher.

Learn MoreWhat Are Jaw Crushers and How Do They Work? | Oreflow

Jaw crushers use compressive force to break down large materials into smaller, more manageable pieces. It has two crushing jaws (one is

Learn MoreHow does a Rock Crusher Work - Jaw Crusher - 911 Metallurgist

SWING AND STATIONARY JAWS on the jaw crusher are annealed cast steel box section construction — designed for maximum rigidity. The jaw swings on

Learn MoreJaw Crusher | manufactor | thyssenkrupp Mining Technologies

All in all, thyssenkrupp’s jaw crushers are convincing due to their rugged and reliable design with high capacities, low wear and tear and high ease of maintenance. The advantages can be summarized as follows: Crushing of hard rock such as granite, basalt and ores. High capacity due to enhanced kinematics of the swing jaw.

Learn MoreBlake Jaw Crusher - Mineral Processing & Metallurgy

1/15 · The original Blake crusher was designed with a vertical stationary jaw. Probably the first departure from this arrangement was an 84 X 66″ crusher, built in 1914. This machine

Learn MoreCrushing technology - kleemann

Jaw crushers operate according to the principle of pressure crushing. The crushed material is crushed in the wedge-shaped pit between the fixed crusher jaw and

Learn Moreconstruction of jaw crusher | crusher parts south africa for joint ventures

Jaw Crushers. Typical applications for jaw crushers are; Ore Mining. Rock Quarries. Sand and Gravel. Construction aggregates. Recycled concrete (concrete, asphalt, etc.) Industrial Applications (slag, anodes, metallurgy, chemical industries etc.) ROC Jaw Crusher. Roc Impact jaw crushers are widely used in mines and quarries around the

Learn More