- [email protected]

- +86-21-63353309

double roll crusher working principle

double roll crusher working principle

Roll crushers - SlideShare

The particles are drawn into the gap between the rolls by their rotating motion and DOUBLE ROLL CRUSHER Working Principle and Structure of Double Roller

Learn MoreAugdouble Roll Crusher Working Principle

Working Process Of Double Toggle Crusher; 2017-11-8in 1858 eblake from the united states invented a new stone crusher and rock crusherhat is jaw crushert could crush solid rocks better as a result it could be used more widelyhe working principle of the double-toggle jaw crusher was a little more complicated than the roll crusher.

Learn MoreDual roll crushers, how they function - Mine Engineer

A roll crusher crushes using compression, with two rolls rotating about a shaft, towards the gap between the rolls. The gap between the rolls is set to the size

Learn MoreDouble Roller Crushers - SolidsWiki

Operation Principle. Double roll crusher is driven by the motor through the pulley or gear shaft opposite two rollers rotate, or were driven by two motors rotate two rollers. Double roll crusher

Learn MoreThe Working Principle Of Double Roll Crusher

Lab Double Roll Crusher . Working Principle. Lab Double-Roll Crusher is consist of the machine base, machine body, rollers, chain wheel, etc.The main drive roller is driven to run by the motor via roller belt, the main roller drive the driven roller to run synchronously by means of chain.Materials falling into the crushing chamber are crushed.This Lab Double-Roll Crusher has body and coupled

Learn MoreDouble Roll Crusher Design Principles

Roll Crusher Construction Operating Principle. Local Rule 47.5 provides The publication of opinions that have no on the basis of wellsettled principles of law imposes needless expense on the public Twin Roll Crusher which it sold to Mallette Brothers in 1974.The Roll Crusher was the crushers control mechanism was constructed adjacent to the roll crusher.The crusher began operation in late 1974

Learn MoreHow does a Double Roll Crusher works - Mineral Processing

28/12/ · How does a Double Roll Crusher works - Mineral ProcessingFor more mineral processing videos visit my Channel:http://www.youtube.com/hsrivastav /vi

Learn MoreMarcy ® Double Roll Crusher - Gilson Company

Double Roll Crushers are designed for single-pass size reduction of medium-hard to hard materials such as rock or ore to a nominal minus 10 mesh.

Learn MoreThe Working Principle of Double Roll Crusher

It is best suited for the intermediate and fine crushing in small and medium sized mine and chemical industry. The biggest compressive strength of crushed materials is 160Mpa. Roller crusher has advantages of simple structure, reliable work, low cost and less over-crush, it's suitable for crushing coal, coke, sinter and other medium hardness

Learn MoreRoll Crusher for Sale | Quarrying & Aggregates

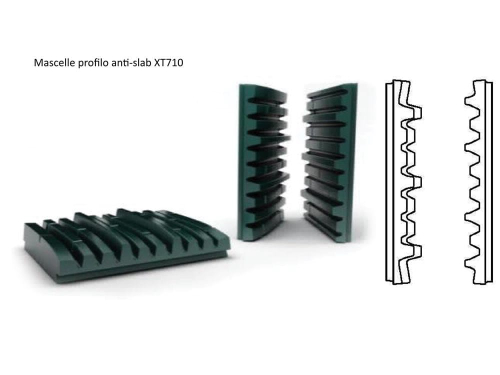

Roller crusher working principle, The main working components of the crusher are 2 parallel crushing rolls. On each roll a certain number of crushing teeth (tooth plates) is fitted along the roll's axial direction. The rolls can turn either inward or outward, depending on property of materials to be crushed and working parameters.

Learn MoreRoll Crusher Working Principle

working principle of crushers Roll crushers - SlideShare. Apr 24, DOUBLE ROLL CRUSHER Working Principle and Structure of Double Roller Crusher 1.this series of roll crusher is mainly formed by the roller, roller support bearing, compression and adjusting device, drive components etc. 2.the adjustment of the particle size: between the two

Learn MoreWorking Principle Of Smooth Roll Crusher Compression

Double roller crusher working Principles: Click & Chat Now. roller crushing working – CGM Project Case. Working Principle of Roll Crushers: A roll crusher crushes using compression, with two rolls rotating about a shaft, towards the gap between the rolls. Click & Chat Now. building up roll crushers – beltconveyers.net.

Learn MoreThe Working Principle Of Double Roll Crusher

Working Principle of Double roll crusher. A roll crusher crushes using compression, with two rolls rotating about a shaft, towards the gap between the rolls. The gap between the rolls is set to the size of product desired, with the realization that the largest feed particle can only be 4 times the gap dimension.

Learn MoreWorking principle of double tooth roller crusher - Exhibition

Working principle of double tooth roller crusher: 1. The working principle of the double-tooth roller crusher The double-tooth roller crusher is

Learn MoreAdvantages and Disadvantages of Roll Crusher

The roller crusher, also known as double roller crusher , is suitable for medium and fine crushing. Its main component is toothed roll.

Learn MoreDouble Roll Crushers | McLanahan

How Double Roll Crushers Work. Operating Double Roll Crushers is quite simple. Whether it is a single or dual drive arrangement, the rolls are powered by electric motors and V-belt drive configurations, resulting in reliable and quiet operation. If it is a single drive arrangement, power is transferred from the driven roll to the non-driven

Learn MoreRoll crusher,Hydraulic double-roll crusher,Cone crusher For

Working principle and structure · 1. This series of roller crushers are mainly composed of rollers, roller supporting bearings, pressing and adjusting devices,

Learn MoreRoll crusher working principle & structure

Double roll crusher is a commonly used roll crusher, whose structure is detailed in Figure 1. Its crushing mechanism is a pair

Learn MoreRoll Crusher - an overview | ScienceDirect Topics

Double-roll crushers are able to crush more finely than single-roll crushers, because they are designed with teeth that mesh together rather than rotating past a smooth plate. They can reduce coal to as little as ¼ inch (0.6 cm) topsize, although they are more commonly operated close to

Learn MoreRoll Crusher Brochure | PDF | Transmission (Mechanics) | Bearing

Roll Crushers. For Uniform Crushing And Sizing With Less Fines, Its Gundlach. Single-Stage and Two-Stage Roll Crushers 2000, 3000, 4000 and 5000 Series Every day, Gundlach crushers demonstrate their proven superiority by producing high product uniformity with less fines, resulting in Lower operating and maintenance costs More saleable and profitable crushed

Learn More