- [email protected]

- +86-21-63353309

manganese liners for crusher

manganese liners for crusher

manganese liners for crusher spare copper-alloy parts book cone

manganese liners for crusher allis chalmer crusher bottom shell bushing Manganese steel wear liners — SRP have a range of liners comprised of different manganese alloys – depending on the material you are crushing, either impact resistance or wear resistance might be a more important consideration for you.

Learn Moremanganese liners for crusher | feeder wear countershaft bushing

HSI Crusher Apron Liners Kenco Engineering's tungsten carbide impregnation process has proven effective in increasing wear life of apron liners in horizontal shaft impact (HSI)

Learn MoreHigh Manganese Cj613 Crusher Liners Mn13cr2 Mn18cr2

High Manganese CJ613 Crusher Liners Mn13Cr2 Mn18Cr2 Jaw Plates Price · 1-Introduction of Jaw Crusher Parts · Features of cone crusher wear parts :.

Learn Moremanganese liners for crusher | water pressure switch

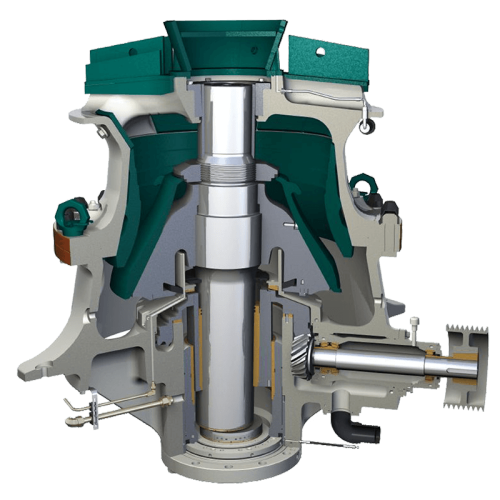

and Cone Crusher Liners material is high manganese steel. After water toughening, a single austenite structure with excellent toughness and non-magnetic properties can be obtained. Its characteristic is that under the action of large impact force and contact stress, its surface layer will rapidly harden, the crystal deforms and

Learn MoreCone Crusher Liners For Popular Brands With Various Material

It is the outer sacrificial wear liner that sits inside the upper frame. Common Aliases: Cone crusher liners, Cone crusher wear parts, Manganese cone liners, Mantle and concave.

Learn MoreCME™ Crusher Liners - H-E Parts

H-E Parts has built a reputation on the reliability and performance of its CME™ range of manganese crusher liners, which are designed to be fully compatible

Learn MoreManganese Parts - Australian Crushing and Mining

We stock a range of the Kawasaki manganese to suit the 800 & 1200 series Cone Crushers. Our Liners are a very high quality and are available in 18% & 22%

Learn MoreManganese Crusher Liners | Mining Wear Parts

GRADES OF MANGANESE. When selecting manganese liners, the liner percentage indicates the amount of manganese used in the casting. Our quality cast liners come in 14%, 18%, and

Learn MoreManganese Crusher Liners | ELRUS Crusher Parts

Jaw and Cone Crusher Manganese Jaw Manganese ELRUS jaw crusher manganese is manufactured to factory specifications and dimensions. All jaw plates are available in 14%, 18%, or 21%manganese content. ELRUS can custom design the tooth profile to meet your specific application needs. Cone Manganese

Learn MoreManganese Steel Rib and Arm Liners for Cone Crusher

Satya Alloy Castings - Offering Manganese Steel Rib and Arm Liners for Cone Crusher, Thickness: 8 - 10 mm at Rs 900/piece in Hyderabad, Telangana.

Learn MoreManganese Mill Liners - Wear Parts For Industry

Manganese Mill Liners By Qiming Casting® ; Name, Spec Available(%) ; Name · C · Si ; High Manganese Liner (Mn14), 0.9-1.5, 0.3-1.0 ; Super Manganese Liner (Mn18)

Learn MoreSamscreen Offers Replacement Crusher Manganese

Not to mention, we carry an extensive variety of crusher manganese for the brands you're most likely to use. Simply call us at (888) 344-3653 and we will be happy to assist you with your replacement crusher manganese needs. Samscreen is pleased to offer a wide variety of replacement crushing products to fit your crushing machine: Powerscreen Extec

Learn MoreCrusher Manganese (Maxwear™ Manganese) - Samscreen

Our crusher manganese replacement parts include: Cones. Jaws. Cheek plates. When you need crusher manganese, Samscreen can help. Contact us online or call us at (888) 344-3653, and one of our friendly, knowledgeable associates will be happy to help you get the Maxwear™ manganese you need quickly, efficiently and with minimal downtime.

Learn MoreTHOR — jaw and cone crusher liners made from inoculated

Upgraded casting technology. Complex inoculation process we use allows forming unique crys- tallization conditions for manganese steels.

Learn MoreWorld-Leading Crusher Liners - CMS Cepcor

Our premium manganese steel and alloy crusher liners are independently proven in mining and aggregate production to achieve and often exceed the performance

Learn Moremanganese crusher liners | SLEEVE H4000

4 - Crusher Wear Parts Reference Guide Crusher Wear Parts Reference Guide - 5 WEAR PARTS OVERVIEW METALLURGY OPTIONS JAW LINERS 18% Manganese Standard fit on all jaw crushers. This is a liner suitable for all applications.

Learn MoreMaterial Used For Crusher Liners - Qiming Machinery

8/30 · Titanium Carbide. It is another renowned material used to manufacture crusher liners. Titanium carbide comes with amazing wearable characteristics that make it a good option for crusher liners construction. Liners that are made of titanium carbide last 2 to 4 times more than normal manganese steel liners.

Learn Moremanganese liners for crusher

Manganese Liner Crusher Liners High Manganese Steel Mantle Bowl Liner For Gp300 Cone Crusher Wear Liners Parts ,000.00-,100.00 / Piece 1.0 Pieces (Min. Order) main frame bushing of stone crushers Crusher Liners – HNS Crushing

Learn MoreMicroalloy Crusher Liners VS Manganese Crusher Liners - Hunan JY Casting

He asks for a report that shows the difference between microalloy crusher liners and normal manganese crusher liners. A total of 80 pcs mircoalloy crusher liners and two additional casting test blocks were produced: 4JI0803 and 3JI1305, corresponding to the heat samples: 4JI0601 and 1JI1504 respectively.

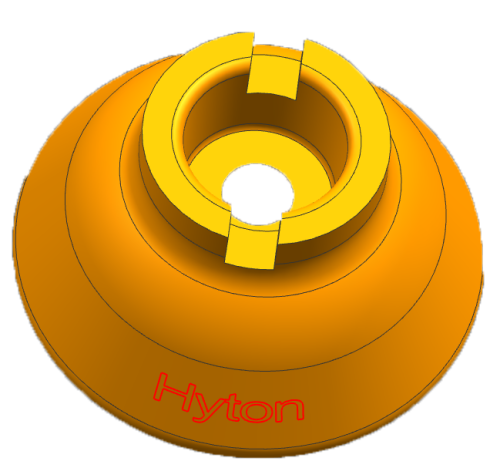

Learn MoreManganese Mantle Bowl Liner Suit Cone Crusher Wear Parts T900

Hyton produce High manganese casting liners mainly include Mantle, Bowl Liner, Feed Cone , jaw plate, check plate, Arm Liner , Steel Ball ,and etc. Cone Crusher Spare Parts-Cone Concave Advantage and Features. 1. Use: Wear parts for crushers in the quarry, mining, cement, aggregate, recycling, shredding and demolition fields etc. 2.

Learn MoreProlonging Cone Crusher Liner Life - Agg-Net

Depending on the stone being crushed, the percentage of manganese in the liners can vary from around 12% to 23%. Care has to be taken during selection, as

Learn More