- [email protected]

- +86-21-63353309

terex pegson jaw crusher manual

terex pegson jaw crusher manual

jaw crusher liner material jaw crusher manual

Mill-Jaw crusher. Laboratory Mill-Jaw crusher.Table instrument Removable jaw for easy cleaning jaw plate and side liner should be ordered in pair. Table instrument High Performance Jaw Crusher. Mar 05, · The 911MPEFC250 Fine Jaw Crusher has a 5″ x 10″ jaw cavity opening suitable for up to 180 Kilos/hr of material either batchwise

Learn MorePowerscreen XA400S / XR400S

Jaw Crushers. PREMIERTRAK 600. Metrotrak. Premiertrak 330. Premiertrak 300. Premiertrak R300. Washing Systems XA_XR400S (T3) Standard Operations Manual Rev p (en) Image Gallery. 1 / 1. Newsletter Signup. Recent Posts. Award Winning Dealership. 13145 Plantside Drive,

Learn MoreMaxtrak 1000 Cone Crusher Plant User Manual PDF

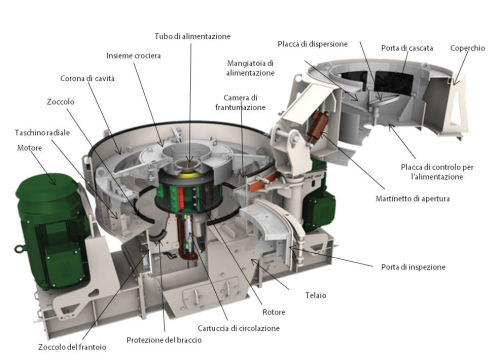

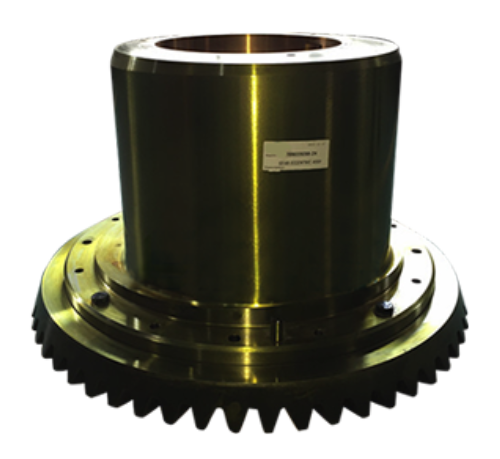

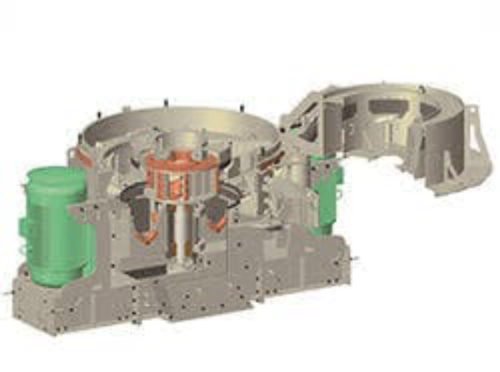

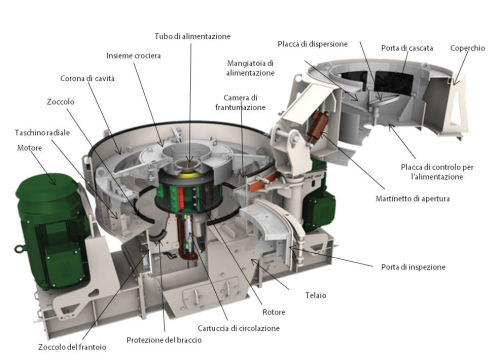

The user manual has specs, diagrams, and actual real photo illustrations, and schemes, which give you complete step by step operations on repair, servicing, technical maintenance & troubleshooting procedures for your cone crusher. This quality manual is 100 percents complete and intact, no MISSING/CORRUPT pages/sections to freak you out!

Learn MoreBL- Premiertrak 1100x650 Specifications ... - LECTURA Specs

See detailed specifications and technical data for BL- Premiertrak 1100x650 manufactured in 1999 - 2006. RA = mobile wheeled, CO = container mobile, SM = semi-mobile; Crusher Type: BB = jaw crusher, KB = gyratory crusher, PB = impact crusher, SB = impact impeller Terex-Finlay C 1545. Operating weight: 43.44 t. Transport length: 16

Learn MoreJaw Crusher Manual

FOTE JAW CRUSHERS 03. Forty Years of Production. Experiences. Henan Fote Mining Machinery. Co., Ltd. is a joint-stock mining machinery enterprise.

Learn MoreXr400 Service Manual - Tattoodo

jaw crusher manual - Henan Mining Machinery POWERSCREEN SHOWS A DIGITAL DISPLAY AT CONEXPO Posted Thursday 23rd Jan 2020. Powerscreen, one of the world’s leading providers of mobile crushing and screening equipment, will attend CONEXPO-CON/AGG 2020. Powerscreen will be exhibiting on booth #S5118 in the outdoor Silver Lot

Learn MoreJaw Crusher Spares & Replacements

For ® Premierplant and Premiertrak Jaw Crusher parts & spares contact CMS Cepcor. We provide replacement parts on a range of Jaw Crushers.

Learn MoreMETROTRAK SPECIFICATION - DCV Engineering

M' Series Single Toggle Jaw. spare crusher shims, operators manual, hopper wedges, jawstock | equipment complies with CE requirements.

Learn MorePDF 1100 x 650 PREMIERTRAK SPECIFICATION - Usługi Dźwigowe TRAKTPDF

JAW CRUSHER Crusher type: 'M' Series Single Toggle Jaw. Feed opening: 1100 x 650 mm. Bearings: Self aligning spherical rollers. Lubrication: Eccentric shaft roller bearings lubricated by grease. Drive: Through wedge belts with screw tension adjustment on engine. 75 mm CSS. Minimum setting: 50 mm closed side on concrete.

Learn MoreCrusher Wear Parts Reference Guide - Corporation

MANUAL. A tight CSS will lead to higher we jaw plates. NB: The crusher must not be operated at a smaller CSS

Learn MoreR Crusher Wear Parts Reference Guide

crusher tools E.G. Jaw liners are subject to numerous pressure and impact stresses. Several other factors affect the wear lifetime of crusher wear parts as listed in below Diagram . Wear

Learn MoreTRACK JAW STYLE 2

world leaders in crushing technology, are renowned for producing high performance jaw crushers that are suitable for quarries,.

Learn MorePDF R Crusher Wear Parts Reference Guide - CorporationPDF

Welcome to the First Edition of the Finlay Crusher Wear Parts Reference Guide . This Guide has been developed to help Dealers personnel to expand their knowledge of Crusher Wear part options & terminology and help relay this information to end users in a clear and logical manner. The Guide is broken down into following sections : 1.

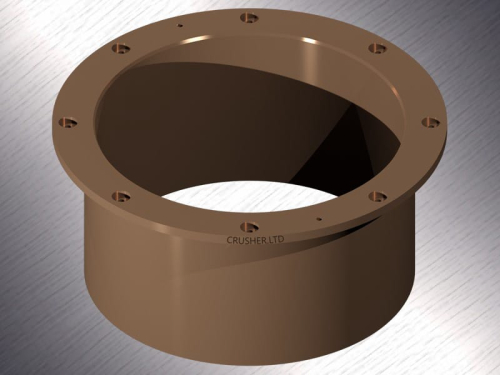

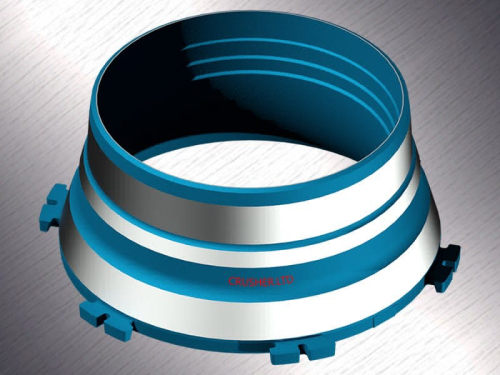

Learn Morecrusher parts | polysius ball mill brass casting

Crusher wear parts. Hot Tags: Fixed jaw Concave Swing Jaw Mantle China Mantle Jaw face. Dec 22, · Browse a wide selection of new and used Crusher Aggregate Equipment for sale near you at MachineryTrader.com. Top models include 1000SR, 4242SR, 428 TRAKPACTOR, and 1000 MAXTRAK

Learn MoreBL- Premiertrak 1100x650 Specifications

See detailed specifications and technical data for BL- Premiertrak 1100x650 manufactured in 1999 - 2006. RA = mobile wheeled, CO = container mobile, SM = semi

Learn MoreMaxtrak 1000 Cone Crusher Plant User Manual PDF - EPCATALOGS

The user manual has specs, diagrams, and actual real photo illustrations, and schemes, which give you complete step by step operations on repair, servicing, technical maintenance & troubleshooting procedures for your cone crusher. This quality manual is 100 percents complete and intact, no MISSING/CORRUPT pages/sections to freak you out!

Learn MoreXA400S & XR400S - Powerscreen - PDF Catalogs | Technical Documentation

The Powerscreen® X400S range of high performance primary jaw crushing plants are designed for medium scale operators in quarrying, demolition, recycling and mining applications. The range includes the XA400S with hydraulic adjust and the XR400S with hydraulic release. User benefits include track mobility for a quick set-up time (typically

Learn MoreCoal Crusher Terex Automax 1000 Manual

automax 1000 manual | Crushing & Screening Plants. The 1000SR combines the incredible 1000 Automax cone crusher with a double deck screen to provide a complete crushing and screening process on a .

Learn MoreManual | A Repair Manual Store

Instant download 2002 Maxtrak 1000 Operarion Installation Parts Maintenace And Service Manual. Machine model : 2002 Maxtrak 1000 Manual Covers: *1 - Safety *2 - Technical Information *3 - General Information *4 - Design and Function *5 - Transport *6 - Set Up *7 - Operating Instructions *8 - Shut Off. $9.99 - Add

Learn MoreCalibration and Troubleshooting Manual - Crane

This manual provides general information and methods for isolating problems that may happen during operation. Service personnel should have previous training and experience in the procedure for setup and operation of this system. Some problems may require replacing or returning parts to the factory for servicing. Tools necessary:

Learn More