- [email protected]

- +86-21-63353309

grinding mill liners

grinding mill liners

Rubber mill liners - Pioneering rubber mill linings - Outotec

Outotec rubber mill liners are tailor-made and developed in close collaboration with our customers. Being the pioneer, Outotec rubber mill linings are designed and produced based on the world's largest bank of know-how and experience. As a result, they last longer and your mill availability increases. Benefits Improved health and safety

Learn MoreChina Grinding Mill Liners Factory and Manufacturers - H&G

grinding mill liners - Manufacturers, Suppliers, Factory from China, "Quality to start with, Honesty as base, Sincere company and mutual profit" is our idea, as a way to build constantly and pursue the excellence for grinding mill liners, reline , L2C Mill liner , ball mill , Check Plate .

Learn MoreGrinding Mill Liner Market Report | Global Forecast From 2022 To 2030

The Global Grinding Mill Liner Market Size is projected to grow at a CAGR of 5.5% from to 2030. In , the metal mill liner segment accounted for the largest share of the global grinding mill liner market. The Asia Pacific is expected to be the fastest-growing region during the forecast period. The growth of this market can be attributed

Learn MoreCutting-edge Mill Liners

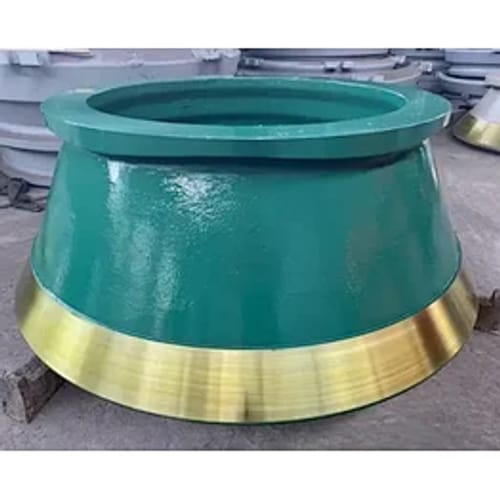

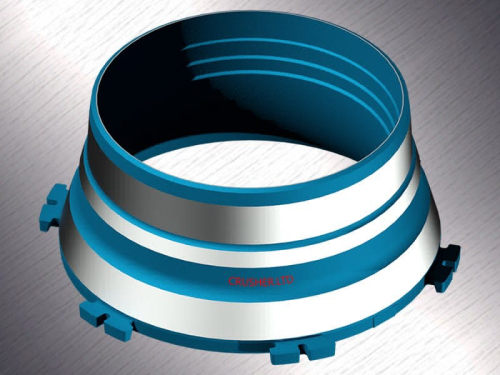

Mill liners fill a basic role: to protect your mills from the intense wear and tear that comes from grinding down hard, raw materials.

Learn MoreKey considerations when selecting a mill lining system - The Weir Group

Rubber and composite mill lining systems In the past, grinding mills were typically lined with cast metal linings of varying steel or iron alloys, and lining system selection was typically driven by level of wear protection and cost. As materials technology and design technique has advanced, today many superior alternatives exist to metal linings.

Learn MoreFive tips on mill liners to improve grinding profitability 2/2

4. Optimized grinding mill liner design. A mill lining should be optimized by design in order to minimize problems, utilize the mill's capacity

Learn MoreGrinding Mill Liners and Wear Parts - Columbia Steel Casting Co., Inc

We offer a full line of parts for rod, ball, and semi-autogenous grinding mills for cement plants. Shell liners We offer many choices in design and alloys for all popular mills, ranging from traditional wave styles to step liners, classifying liners and SAG mill liners. Trunnion liners Not many foundries are capable of making trunnion liners.

Learn MoreBall Mill Liners Selection and Design | Ball Mill Rubber Liner

The mill liner is installed inside the ball mill barrel, separating the grinding media from the barrel, effectively buffering the direct impact of the grinding media on the barrel. Therefore, the barrel is protected, and the service life of the barrel and the entire ball mill equipment is prolonged.

Learn MoreGrinding Mill Liners factory, Buy good quality Grinding Mill Liners

Customized Size Ball Mill Liner , Cement Mill Liners Multifunctional. Keywords:Ball Mill Liner Board Plates. Technology:Casting. Application:Mining,Cement plant,Power Station

Learn MoreCeramic Liner Ball Mill Machine Price Ball Grinding Mill Small

About Press Copyright Contact us Creators Advertise Developers Terms Privacy Policy & Safety How works Test new features Press Copyright Contact us Creators

Learn MoreGrinding Mill Liner Bolts Abrasion Resistant - EB Castworld

Mill liner Bolts used for holding Liner plates and Cheek plates in position in Jaw crushers and Impact crushers. These type of Mill Liner Bolts are used for ball Cement Industry Plants. Including: Mill liner Bolts Oval head liner bolts Square head liner bolts Hex head liner bolts Tee head liner bolts Liner Plate Bolts

Learn MoreShell Liners | Crusher and Mill Liners | CITIC HIC

CITIC HIC has a wear liner production base with annual capacity of 30,000 tons of wear-resistant castings. At the production base, we can produce a variety of wear liners for crushers, grinding mills and vertical stirred mills. Through from casting process design, mold making, smelting & casting, heat treatment, quality inspection, to packaging

Learn MoreBetter Surface Quality With Dia3.8m Steel Cement Mill Liners DF067 For

Mill Liners for sale, Quality Better Surface Quality With Dia3.8m Steel Cement Mill Liners DF067 For Grinding Cement on sale of Zhengzhou Qianyue Mill Liners Co., Ltd. from China.

Learn MoreMill linings - Element

One of the key areas of Element is mill lining. Here, we offer lining solutions for the most complex product used for grinding ore in mining factories.

Learn MoreQuality Ball Mill Liners & Mill Liners Manufacturer

Wuxi Orient Anti-wear Co., Ltd. We are a specialized manufacturer of wear and heat resistant castings. Our main products are Mill Liners for Ball Mills,SAG Mills,AG Mills,Crusher Wear Parts and Grinding Media. 1. The Production 1T,1.5T,3T,5T,12T,15T Induction Electrical Furnace Heat Treatment Electrical Furnace Process.

Learn MoreGrinding Mill Liners- An Overview

Grinding Mill Liners- An Overview · Solid liners · These are single units with integral lifters and fewer pieces but the downside is a higher

Learn MoreFive tips on mill liners to improve grinding profitability 1/2

If the lining is transmitting the energy from the rotating mill to the charge, the grinding media is doing the actual grinding work. Breaking rock of a certain size and with certain properties requires a certain energy - and that determines the top media size. To get the final finer product, smaller sizes of media are required.

Learn MoreSelection and Design of Ball Mill Liners

According to different grinding requirements, ball mill liners are roughly divided into 9 types, which are wedge-shaped, corrugated, flat-convex

Learn MoreGrinding Media, SAG Mill Liner, White Iron Mill Liner - H&G

Sep-18-2021. H&G deliver 2 sets of high manganese steel mill liner for SAG 5.5*1.8 H&G deliver 2 set

Learn MoreApplication of multi regressive linear model and neural

The liner of an ore grinding mill is a critical component in the grinding process, necessary for both high metal recovery and shell protection.

Learn MoreRemaining useful life prediction of grinding mill liners using an

Liner wear influences the grinding performance in the context of metal recovery. •. We estimate remaining height and life of the liners with artificial

Learn More