- [email protected]

- +86-21-63353309

crushing plant operation pdf

crushing plant operation pdf

PDF) Factors affecting the performance of crushing plant operations

In mining operations, the layout of crushing plants and ancillary equipment and structures is a crucial factor in meeting production requirements while keeping capital and operational costs to a

Learn Morestone crushing plant pdf

The plant operator/utility worker must make sure that empl oy ees, drawing mobile coal crushing plant pdf ndash samac. stone crusher plant design cad

Learn MoreMODELLING, SIMULATION AND OPTIMISATION OF ... - CORE

operation used to achieve size reduction of minerals and ores. Crushing plant. An arrangement of equipment which reduces or.

Learn MoreMobile Crushing & Screening Plants Brochure - Corporation - PDF

The LT1110 is commonly used for crushing medium hard rocks and for recycling. It can crush any recycled material from asphalt to concrete and bricks. The ® NP1110M™ impact crusher always provides high capacity and a high reduction rate. LT1110 is built around the powerful NP1110M impact crusher from the proven NP series.

Learn MoreCrusher Plant Operation Pdf Samac Coal Surface Mining

OPERATION AND MAINTENANCE OF CRUSHER HOUSE 2015-4-10 OPERATION AND MAINTENANCE OF CRUSHER HOUSE FOR COAL HANDLING IN THERMAL POWER PLANT Girja Lodhi1* *Corresponding Author: Girja Lodhi, [email protected] Many utility systems in the world have power plants operating with fossil fuel. In the thermal power plants maximum requirements of fuel is a coal.

Learn MoreCrushing Plant Environmental Operation - Henan Mining Machinery and

Crushing Plant Environmental Operation. Prompt : Caesar is a famous mining equipment manufacturer well-known both at home and abroad, major in producing stone crushing equipment, mineral separation equipment, limestone grinding equipment, etc. Crushing Plant - Business Environmental Impact Assessment study for the stone crushing project on

Learn Morecrusher plant operation pdf

Mobile Crushing Plant YCZ series mobile crushing plant consists of crushing and screening, reasonably combined with tyred trailer. It could move flexibly based on change of working site. 0086-371-63769782 salesgreatwallcrusher.

Learn MoreCrushing Plant Dynamics - Chalmers Research

A crushing plant's operating performance depends on the design and configuration of each individual process unit, the configuration of the

Learn MorePDF ROCK CRUSHING PLANT APPLICATIONS ADVICE - Oklahoma Department of ...PDF

In general, a rock crushing plant will have a primary crusher, primary screen, secondary crusher(s) and secondary screen(s), and associated conveyors and stockpiles. It may also For batch drop operations (unloading by front-end loaders), download Section 13.2.4. A 70% control efficiency may be applied for damp material.

Learn MoreSAND, GRAVEL, AND CRUSHED STONE ON-THE-JOB

For the job of plant operation, this module describes the basic job steps, potential hazards and accidents, and the recommended safe job procedures. These job

Learn MorePDF Crushing Plant--Hydraulic Cone CrusherPDF

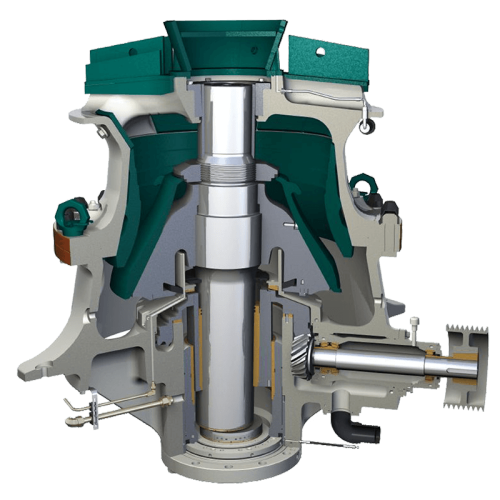

There are two routes for the oil to enter the machine, one is through the oil hole at the bottom of the crusher, then to the hollow eccentric shaft surface, bowl-shaped bearing and the big and small gears through 3 separate ways. The other is through the hole in the transmission shaft support, then to the transmission bearing.

Learn MoreFULLTEXT01.pdf - DiVA portal

these of a crushing circuit in a mining plant (Rylander and Axelsson, detailed description of the mechanical operating aspects of cone.

Learn Morechapter 4 process plant design

The crusher selection was made by Minerals based on Yanqul ore characteristics This flotation cell arrangement allows the plant to be operated in

Learn MorePDF AP-42 Section 11.19.2 Crushed Stone Processing and Pulverized ... - US EPAPDF

deposit. Processing operations may include crushing, screening, size classification, material handling and storage operations. All of these processes can be significant sources of PM and PM-10 emissions if uncontrolled. Quarried stone normally is delivered to the processing plant by truck and is dumped into a bin.

Learn MorePDF) SIZE REDUCTION BY CRUSHING METHODS - ResearchGate

3/4 · There are two major categories of processing. One is comminution and the other one is separation. The process "Comminution" involves size reduction and size-wise classification called as screening

Learn MorePDF MOBILE PROCESSING - Wirtgen GroupPDF

Pressure crushing machines are generally used because of their cost-effectiveness and efficiency. Observing the required grain shape is challenging during the production of asphalt aggregate grain sizes. The material flows must be carefully adapted to each other to ensure continuous and efficient processing.

Learn MoreCrushing Resource Book - 911 Metallurgist

This unit is about how we manage crushing within the processing plant mining operation to remove the ore from the ground and make it easier to be

Learn MoreCRUSHING SCREENING

In addition to being our most efficient crushers with the lowest operational costs, vertical shaft impact crushers tolerate moisture and stickiness, and have a drying effect on the material,

Learn MoreMobile crushing & screening plants

Crusher ®NP1110M™ Feed opening 1 040 x 800 mm (41 x 31”) Engine CAT®, 224 kW (300 hp) Weight 32 000 kg (71 000 lbs) The ®LT1110™ is our most compact impactor plant on tracks. The LT1110 is commonly used for crushing medium hard rocks and for recycling. It can crush any recycled material from asphalt to concrete and bricks.

Learn MoreMineral Processing Plant Design

In mining operations, the layout of crushing plants and ancillary equipment and structures is a crucial factor in meeting production requirements while keeping

Learn MoreCrushing Plant Startup Sequence & Procedure

The Crushing Plant operator must ensure that the dust scrubber has an adequate supply of reclaim water and monitor flow-meter to ensure that the proper amount of water is being recirculated through the scrubber. Under normal conditions, the dust scrubber requires a minimum recirculation of 8 to 10 cubic meters per hour.

Learn More