- [email protected]

- +86-21-63353309

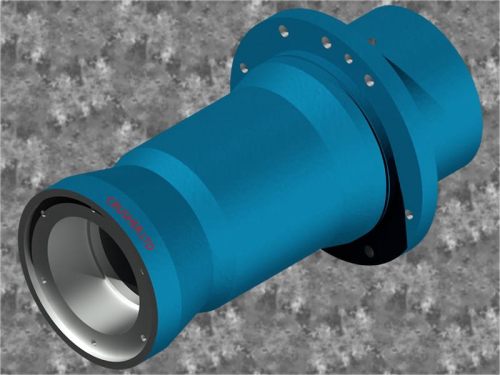

cone crusher lubrication system

cone crusher lubrication system

CH860i & CH865i CONNECTED CONE CRUSHER

complete lubrication system, increasing uptime and reliability. It can automatically adjust crusher settings to compensate for crushing chamber wear,

Learn MoreHydrocone Crusher - DiVA portal

There are two hydraulic systems on the Hydrocone crusher, the hydroset for positioning the main shaft and the lubrication system.

Learn MoreCone Crusher Lubrication System

The cone crusher is composed of frame, transmission, adjustment device, hydraulic system and lubrication system. The lubrication system is an indispensable device for each crushing machine to ensure the good lubrication of the equipment and provide the crushing work for the cone crusher. condition. How the lubrication system works. The pressure

Learn MoreLubricating crushing machines in quarries - Rock to Road

The actual crusher can be in the form of a cone, gyratory, impact, jaw, etc. For crusher systems that use oil lubrication for example, contamination of

Learn More4 Common Problems of Multi-cylinder Cone Crusher

The function of lubricating oil for multi-cylinder hydraulic cone crusher is to lubricate and dissipate heat. Poor lubrication can easily cause severe wear of the copper sleeve (copper shavings and copper skin on the oil return filter screen), or even a burnt copper sleeve.

Learn MoreCone crusher lubrication system maintenance precautions

The lubrication system plays an important role in the work of the cone crusher. The maintenance of the lubrication system can improve the production efficiency of the cone crusher. Jiaozuo Zhongxin technical engineer introduces the maintenance points of the equipment lubrication system. First, the lubricating oil, it can be said that the lubricating oil is the key to the lubrication system of the cone crusher.

Learn MoreEp-100 | Cone crushe lubrication system | cone oil system | oil

Jai Hind,about this video,cone crushe lubrication system.cone crushe oil circulationcone crushe lubrication system me kon kon se safety device lage rahten ha

Learn MoreCN105251561A - Hydraulic lubrication control system for cone crusher

The hydraulic lubrication control system for the cone crusher comprises a crushing main unit. The crushing main unit comprises a shell, wherein the shell is provided with a feed inlet and a discharge outlet. A main shaft which can eccentrically rotate in the circumferential direction and is provided with a movable cone is arranged in the shell.

Learn Morecone crusher lubrication station

Five steps to optimize crusher''s lubrication system. Jul 30 1 Monitoring of lube oil temperature A lot can be learned about a cone crusher by simply

Learn MoreOil Lubrication And Filtration System For Cone crusher I

11/06/ · Lubrication oil circuit pushes oil through the crusher bearings. During the operation of the stone crushing, heavy dust produces and enters in to the lubrica

Learn Moreen/lubricating system cone crusher manual.md at main - GitHub

Here are nine common senses users need to know about the lubrication system of cone crushers.1.Lubricating oil enters.UK manufactured cone crusher.Manual.

Learn MoreLubricating System For Simons Cone Crusher

Cone Crusher; Lubricating System For Simons Cone Crusher. May 06, The cone crusher adopts thin oil circulation lubrication. It has two kinds of lubrication systems: one is the oil pump driven by the power of the drive shaft, called the integral lubrication system; the other is the lubrication system driven by the oil pump alone.

Learn MorePerfect Lubrication System Cone Crushing for Mine/Coal

Also cone crusher uses the compensating lubricating grease sealing, it can avoid lubrication oil being polluted by dust, so that all parts work reliably and have a long operating life. The safety insurance system of cone crusher uses several spring sets, so the matter and iron ore are down from the crushing cavity and do not damage the crusher, simply and reliably.

Learn Morecone crusher manual | Henan Deya Machinery Co., Ltd

31/03/2022 · This is an installation and use manual for cone crusher operators. For experienced personnel, reading this manual will make you more familiar with the machine. The instructions and diagrams in this manual will help you to properly check, start and operate the crusher and its auxiliary equipment.

Learn MoreHow to protect cone crusher lubrication system in Winter season?

Cone crusher usually works in factory, if you use for heat preservation measures, we should install corresponding electric heating devices the fuel tank so as to improve lubricating oil temperature before starting and ensure the smooth work in lubrication system . When cone crusher works about 1200-2000 hours, lubricating oil reaches the use of time and it should be replaced new lubricating oil, At the meanwhile , we clean oil tank and oil pipe .

Learn MoreCone Crusher Lubrication System Manufacture and Cone

Cone Crusher Lubrication System - manufacturer, factory, supplier from China. Hot Sale Concrete Impact Crusher With High Efficiency. Cone Crushers are Suitable for all Crushing Needs. SANLAND ST-0100 cone crusher. Sanland Cone Crusher is your needs. GP Series Cone Crushers For Sale.

Learn Morecone crusher lubrication system

21/10/ · About Press Copyright Contact us Creators Advertise Developers Terms Privacy Policy & Safety How works Test new features Press Copyright Contact us Creators

Learn MoreCommon Senses on Lubrication System of

When the lubricating system of cone crusher is not working, the oil level in oil receiver should reach the upper limit.

Learn MoreGrease Lubricating System Used in Different Types of Stone Crusher

23/10/ · Normally, operating an oil-lubricated crusher with contaminated lubricating oil (old, dirty oil) is a common mistake followed by maintenance people. As a thumb rule, operators should use gear lubricants added with extreme pressure additive with a minimum oil viscosity of 22 CST at the bearing operating temperature.

Learn MoreJaw Crusher Lubrication Knowledge Analysis | 2019-09-10

Since the large and medium jaw crusher bearings and the eccentric shaft are pressure cycle lubrication, when the oil pump fails, the jaw

Learn MoreCH830i Cone crusher — SRP

The standard of-fline filter unit keeps lubrication oil cleaner with 24/7 fine filtration, reducing we your internal crusher components and extending oil life by up to 5 times. Advantages Automation & Connectivity System (ACS) Automatically adapts the crusher to varying feed conditions ensuring maximum 24/7 performance

Learn More