- [email protected]

- +86-21-63353309

tube making process

tube making process

The Wine Making Process from Start to Finish at Adirondack Winery

Adirondack Winery's Wine Making Process de-mystified! Since most of you who visit our Tasting Rooms in Lake George and Bolton Landing have never seen HOW we make our delicious Fruit Infused Wines,

Learn MoreCold drawn seamless steel tube process - Sunny Steel

Cold drawn seamless steel tubes process: round tube → heating → perforation → Heading → annealing → pickling → oiled (copper) → multi-pass cold drawn (cold rolled) → blank tube → heat treatment → straightening →hydrostatic testing (testing) → mark → storage.

Learn MoreMaking Memory Chips – Process Steps

From laptops to mobile phones to connected cars and homes, memory and storage are helping change how the world works, plays, communicates and connects. Check

Learn MoreHow to Make Grape Juice {the Easiest Way!} - The Seasoned Mom

Place 1 cup of grapes in a quart-size mason jar. Pour ½ cup of sugar over the grapes. Add boiling water to fill the jar about halfway. Stir until the sugar dissolves in the hot water. Fill the jar the rest of the way with boiling water, leaving a ¼-inch of headspace at the top. Secure the lids and rings.

Learn MoreWhat is Wire Drawing, Tube Drawing and Making? - ExtruDesign

This roughly formed seamless tube is further rolled in a “plug rolling mill”. The final operations of “reeling” and “sizing” are further conducted on the cooling tubes to improve the size and finish tubes. Conclusion. We have discussed the wire drawing process and the tube drawing and making of tubes with the schematic diagram.

Learn MoreWhat does a Process Engineer do? Role & Responsibilities

Process engineers spend their workdays managing the operations of a manufacturing facility. Some of their common daily tasks include monitoring the plant's production processes, testing and maintaining equipment, overseeing the safety of employees, and ensuring the factory maintains compliance with local and federal regulations.

Learn MoreUS2628516A - Tube making process - Google Patents

US2628516A - Tube making process - Google Patents Tube making process Download PDF Info Publication number US2628516A tube mandrel cavity Prior art date 1949-07-09 Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the

Learn MoreTube filling equipment

Tube filling equipment A tube is a collapsible package, made of plastic or metal, used for packaging highly viscous liquids or pastes. Considerations for choosing a suitable tube filling system include the nature and viscosity of the product to be filled, the tube material, capping requirements, and the desired filling speed and volume.

Learn MorePipe and Tube Marking Marking Process for Your Company

The dot peen marking machine is portable, easy to use, and can mark large size pipes and tubes with outright efficiency. You can check how to use it here. Weight: around 3.5 kg. Marking area: 140mmx60mm (HS-PE01) & 70mm x 20mm (HS-PE02) Marking speed: 30-40mm/s. Power supply: AC 100V-240V.

Learn MoreTube Making Process_Shandong Jinding Stainless Steel Tube Co.,Ltd

Tube Making Process-Shandong Jinding Stainless Steel Tube Co.,Ltd-Theprocessflowfortheproductionofsteelpipesisasfollows:1.Samplepreparation

Learn MoreSteel Pipe Manufacturing Processes - mandrel mill process

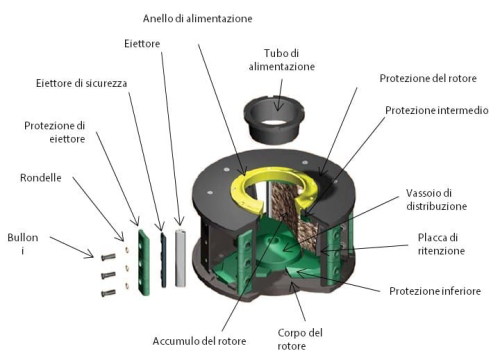

The pierced billet or hollow shell is rollreduced in outside diameter and wall thickness. The rolled tube simultaneously burnished inside and outside by a

Learn MoreChina Welded Tube Making Process Supplier and Factory, Manufacturers

Getting started; Welded Tube Making Process; Welded Tube Making Process - Manufacturers, Factory, Suppliers from China. We can easily normally satisfy our respected buyers with our excellent high-quality, excellent selling price and good service due to we've been far more expert and more hard-working and do it in cost-effective way for Welded Tube Making Process, Alloy Steel Pipe Manufacturers

Learn MoreWelded vs Seamless Stainless Steel Tu

The tu is manufactured through an extrusion process where the tube is drawn from a solid stainless steel billet and extruded into a hollow form. The billets

Learn More4 Steps to Make a Paper Tube - Spiral Paper Tube & Core

Step 4: Cut the paper tube. The cutting unit the final step in the process. Some manufactures use saws to cut the paper tubes while others use knives. The image below shows a manufacturer using rotary knives. The paper tube is being directed into the cutting unit, and at the right time, all of the rotating knives will come in towards the paper

Learn MoreEasy Customer Login - Let's make the login process easy and simple for

Customers can easily register or login to your website through their mobile phone number. This is a fast and easy process where the customer enters the phone number and an OTP is generated by the App and sent to the customer's mobile for authentication within few seconds. Customers can login immediately after entering the OTP login code.

Learn MoreCN103331326A - Tube making process of high molybdenum alloy

Jul 04, · The invention discloses a tube making process of high molybdenum alloy. The process comprises the following steps of: (1), detecting a blank material and performing primary acid pickling; (2) performing endoscopy, polishing, rolling for deforming, deoiling and inner and outer surface inspection on the tube blanks subjected to acid pickling to obtain a semi-finished

Learn MoreStainless Steel Pipe and Tube Manufacturing Process

In the tubes-mill, the strip is gradually converted into the tubular shape. The fitted welding machine is then used to weld trim edges of the strip using TIG

Learn MorePaper Tube: What Is It? How Is It Made? Types, Uses - IQS Directory

The paper tube material is rotary or saw cut into paper cans or composite cans, shipping tubes, push tubes, pyrotechnic tubes, display poles, converting cores, concrete piling forms, and other paper tube products. Large fiber or composite drums and even paper straws are manufactured in a similar winding process.

Learn MoreTube Making Process - Permanent Steel

Jan 21, · Tube Making Process 1. Sample preparation: In order to facilitate the inspection, the production and installation accuracy of the steel pipe 2. Steel plate splicing and blanking:

Learn MoreProcess of Tube Drawing | Metallurgy - Engineering Notes India

The cylindrical mandrel and the tube are pulled together through the die. The process is generally used to reduce the thickness of tube. Since the area of cross section of tube increases towards the entry side its speed decreases while the mandrel being rigid moves with the same speed as the speed of tube at the exit.

Learn MoreTube and pipe manufacturing - the basics - Expometals

Tube and pipe manufacturing Tubular steel products are manufactured mainly by two different methods resulting in seamless pipes or in welded pipes. The

Learn More