- [email protected]

- +86-21-63353309

feed stage distillation column

feed stage distillation column

Beyond Reflux and Tray Count, Chemical Engineering ... - ERIC

In this work, different alternatives for locating the optimal feed stage in a distillation column as well as the effect of the feed temperature are studied,

Learn MoreEquilibrium Separation Column

One of the first design steps required for distillation column is to determine the number of theoretical stages required and the feed location.

Learn MoreOptimization and Dynamics of Distillation Column Using

upon is finding the optimum feed tray locations of distillation columns. observed that minimum reboiler duty is 40.8 MW when feed is at stage 10

Learn MoreStage-to-stage calculations of distillation columns by fixed-point

Jun 08, · For simplicity, a distillation column with one single feed on stage N F (N F = 2 in the example of Fig. 2) and without any side-draws is considered. The method described in the

Learn MoreOptimization of Feed Locations for Double-feed Columns

It is found that the appropriate feed stages of a double-feed column are positions For chemical plants, typical double-feed distillation columns are

Learn Morefeed-stages-in-a-distillation-column - LearnChemE

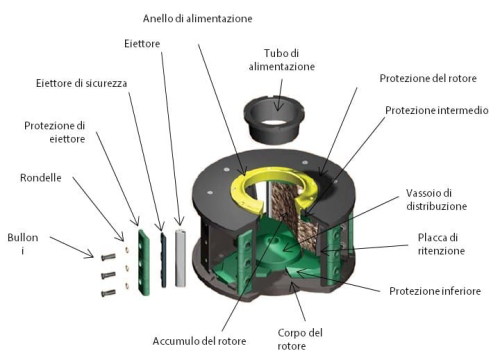

The flow rates to and from a feed stage of a distillation column are proportional to the thickness of the arrows in the figure. Liquid (blue) flows down the column and vapor (green) flows up.

Learn MorePDF A simple design method for multicomponent distillation columnsPDF

The discrepancy between the feed stage compositions thus computed is used to revise the products compositions. However, this method did not gain acceptance and currently there are Stage N Figure 1: (a) A distillation Column & (b) Feed Stage F, z fi, q Feed Stage V f+1 y f+1,i T f+1 (a) (b) L f x f,i T f V f y T f L f-1 x f-1,i T f-1 F, z fi

Learn MoreAnalysis of the effect of feed composition and thermal

A trayed distillation column is normally divided into a series of stages to allow multiple liquid-vapor contacting leading to a cascade of equilibrium stages.

Learn MorePDF CHEMCAD SCDS Column - web1.eng.famu.fsu.eduPDF

CHEMCAD SCDS Distillation Column, page 1 of 17 08December2005 CHEMCAD SCDS Distillation Column SUPERTEAM 2005 Experiment 300 ECH4404L By: Lakshmi Kastury Subcooled delta T, enter 32.2 C. For the number of stages enter 6, and for the feed stage for stream 1 enter 2. Figure 9 Note: 1. Actual number of stages is 6, consisting of 4 trays plus a

Learn MoreFeed Stages in a Distillation Column

Feed Stages in a Distillation Column. feed quaty. 07. The fow rate t n ro ee tag f dst aton coumn are proport n t th thckness f th arrows n the fgure. Lqud (bue) fows down the coumn and vapor

Learn MoreIf we increase feed rate into a distillation column, do we have to make

It really depends on what you are feeding as much as the feed rate. Let's say you are distilling alcohol. If you heat exchange the waste water with the feed you only concern your self with how much alcohol is coming into the column. That means you maintain the same product to reflux ratio no matter your feed rate. Donald Pearline

Learn MoreDistillation Column - an overview | ScienceDirect Topics

A typical distillation column consists of several major parts: 1. A vertical shell where separation of the components is carried out. 2. Column internals such as trays, or plates, or packings that are used to enhance component separation. 3. A reboiler to provide the necessary vaporization for the distillation process. 4.

Learn MoreDistillation Column Design - COSTELLO

Determining the number of stages required for the desired degree of separation and the location of the feed tray is merely the first steps in producing an

Learn MoreImpact of Feed on Liquid and Vapor Flows in a Distillation Column

Organized by textbook: https://learncheme.com/Uses an interactive simulation to describe the impact of the state of the feed to a distillation column on the

Learn MoreAnalysis of the connecting zone between consecutive sections

Tray by tray methods for the design of distillation columns cannot compete with column, it flashes adiabatically and spontaneously to the feed stage

Learn MoreColumn distillation optimum feed stage - Big Chemical Encyclopedia

A distillation column will use the optimum feed stage. A liquid side stream is withdrawn on the third stage below the total condenser at a rate of 15.0 kmol/h. The feed is a two phase mixture

Learn MoreDistillation Column: Types and Designing Consideration

1 Types of Distillation Columns. 1.1 Batch Column. The feed to the column is added batch by batch in this process. After charging the column with a “batch,” the distillation process begins.

Learn MoreColumn distillation stages, calculating number - Big Chemical Encyclopedia

Distillation stage calculations are usually performed with ideal stages, The number of ideal stages required for the separation is divided by the overall column efficiency (Sec, 7,1,1) to obtain the required number of trays. In packed towers, the number of stages in the column is multiplied by the HETP ( Height Equivalent of a Theoretical Plate

Learn MoreFactors Affecting Distillation Column Operation

The state of the feed mixture and feed composition affects the operating lines and hence the number of stages required for separation. It also affects the location of feed tray. During

Learn MorePDF Chapter 4: Column Distillation: Internal Stage-by-Stage Balances - TUPDF

We can perform the internal stage-by-stage balances from either the top (i.e.a condenser) or the bottom (i.e.a re-boiler) of the column 2 In the enriching (rectifying)section (i.e.the section above the feed stage), it is convenient to perform the balances for the area that goes around the desired stage and the condenser

Learn MorePDF Aspen Tutorial #6: Aspen Distillation - University of WashingtonPDF

The DSTWU unit operation is designed for single feed, two product distillation processes. This column completes calculations using Gilliland's, Winn's, and Underwood's methods for calculations of stages and reflux ratios as indicated in Table 1. These calculations are completed based on two assumptions, constant molar overflow and

Learn More