- [email protected]

- +86-21-63353309

jaw crusher and gyratory crusher

jaw crusher and gyratory crusher

Gyratory Crusher HOW IT WORK | Crusher Mills, Cone Crusher, Jaw Crushers

Gyratory crusher,primary gyratory crushers maintenance,working if you have used Gyratory Crusher of questions,gyratory crusher sizing how gyratory crusher works - Crusher South Africa how a gyratory crusher works | Crusher Solutions Gyratory and cone crushers work in pretty much the same way, although they have slightly

Learn MoreHow Gyratory Cone Crusher Works | Crusher Mills, Cone Crusher, Jaw Crushers

Jaw-type gyratory crusher type BK 160-190 Two Ciros® cone crushers installed in a gravel works. Capacity: approx. 60t/h each. how gyratory crusher works - Crusher South Africa. how a gyratory crusher works | Crusher Solutions Gyratory and cone crushers work in pretty much the same way, although they have slightly different designs.

Learn MoreJaw crusher - SlideShare

Gyratory Crusher • A gyratory crusher is similar in basic concept to a jaw crusher, consisting of a concave surface and a conical head; both

Learn MoreJaw Crusher VS Gyratory Crusher - Luoyang Dahua

Comparison of performance advantages of gyratory crusher and jaw crusher. The outstanding advantage of the gyratory crusher is that the crushing wall is large, which can reach -9.5, and sometimes it can be as high as 13.5. The production efficiency is high, and the work is relatively stable. Either side can feed ore and can be crowded with ore.

Learn MoreStone Crusher For Sale Philippines-SBM Industrial Technology Group

In mine processing and production, jaw crusher and hydraulic gyratory crusher are usually used as primary crushing equipment. Among them, jaw crusher is widely used in Philippines and other countries. However, with the continuous improvement of the country's requirements for the green development of sand and gravel mines, enterprises have

Learn More3 Types of Crushers - Optimum Crush

There are two kinds of jaw crushers: single toggle and double toggle. The single toggle jaw crusher uses a Shaft rotation for a compressive action. The double toggle crusher has two shafts toggle plates each. Gyratory crushers. Gyratory crushers are mostly restricted for primary crushing purposes, but they see some usage for secondary crushing

Learn MoreCrushers - All crusher types for your reduction needs - Outotec

The disadvantage of this type of crusher, when high capacity is required, is the relatively small discharge width, limiting the capacity as compared with the discharge circuit of a gyratory crusher. Jaw crushers are mainly used in plants producing up to approximately 1600 t/h. Primary crushing with gyratory crushers

Learn MoreGyratory Crushers | Crusher Mills, Cone Crusher, Jaw Crushers

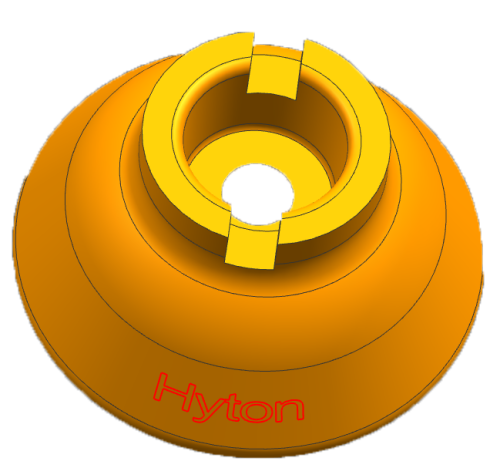

gyratory crusher ( jrtr krshr ) ( mechanical engineering ) A primary breaking machine in the form of two cones, an outer fixed cone and a solid inner erect, Gyratory Crusher Parts,Gyratory Crusher Offers Manufacturers,

Learn MoreThe comparison between Gyratory Crusher with Jaw ... - PRLog

here we will make a difference between jaw crusher and gyratory crusher. 1.The crushing of gyratory crusher is continuously, so gyratory

Learn MoreGyratory Crusher | Hazemag North America

A gyratory crusher is one of the main types of primary crushers in a mine or ore processing plant. Gyratory crushers are designated in size either by the

Learn MoreCrushing, screening, feeding and plant solutions

Traylor and Fuller-Traylor gyratory crushers of the early. 1900s. crushers have proud to add their new line of single toggle jaw crushers,.

Learn Morebetween gyratory crusher and a cone crusher

Gyratory Crusher Cone Crusher Mantle Differences Jul 25 Difference between jaw crusher and gyratory crusher Any of you that are at all familiar with the

Learn MoreType of crushers and their difference - JXSC Mining

10/12/ · Jaw crusher is used as primary crusher, it’s reduction ratio is usually 6:1. It uses compressive force to break the material, this mechanical pressure is achieved by the two jaws of the crusher. Similar to a jaw crusher, the gyratory crusher pulverizers the stones by placing them between two manganese steel plates and going straight down

Learn MorePDF 2. Gyratory CrushersPDF

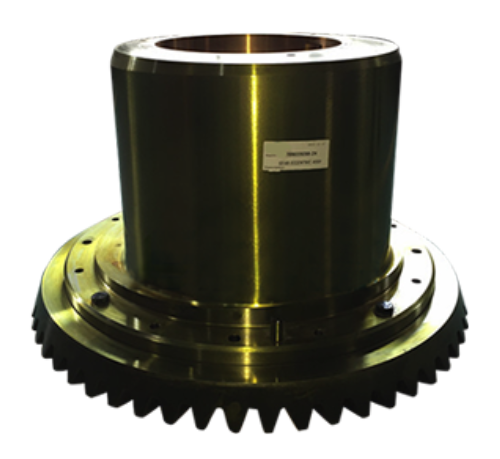

jaw and gyratory crushers. Manufacturers redesigned their gyratories to reduce the feed opening, decrease the closed-side setting, and in- The gyratory crusher has been built in three types known respec- tively as the suspended-spindle, the supported-spindle and the fixed- spindle type. The second type, with the hydraulic piston as the sup

Learn MoreDifference Between Jaw Crusher and Gyratory Crusher - JXSC

The gyratory crusher is continuous crushing. Its outstanding advantage is high productivity, the ratio of crushing is big, up to 6-9.5. Some of the crushing ratios can reach 13.5, and the work is smooth, vibration is small. Jaw crusher is intermittent crushing, crushing efficiency is relatively low.

Learn MoreJaw and Gyratory Crushers | Materials | Manufactured Goods

Jaw and Gyratory Crushers - View presentation slides online. Scribd is the world's largest social reading and publishing site. Open navigation menu. Close suggestions Search Search. en

Learn MoreWhat Type of Crusher Is Best for Primary Crushing?

Types of Primary Crushers · Gyratory Crushers · Jaw Crushers · Hammermills · Horizontal Shaft Impact Crushers · Sizers · Roll Crushers · Cone Crushers

Learn MoreWhat is a Gyratory Crusher | Quarrying & Aggregates

The gyratory crusher is a typical mining compression crusher, which is widely used in the coarse crushing of abrasive or high compressive strength rocks. Gyratory crusher vs jaw crusher. Compared with the jaw crusher, its advantages are: The crushing process of the gyratory crusher is to rotate one circle along the annular crushing cavity

Learn MoreCompare Gyratory Crusher vs Jaw Crusher

The Jaw crusher is the smaller of the two and its single feed point will make it a logical choice for underground workings. In the actual

Learn MoreGyratory Crusher Explained - saVRee

Gyratory Crusher Components Gyratory crushers were invented by Charles Brown in 1877 and further developed by Gates in 1881 (they were commonly referred to as

Learn MoreThe Features and Differences between Jaw Crusher and Gyratory

02/09/ · d. It is required to feed the ore with a uniform particle size, otherwise the crusher is easy to be blocked, and the miner must be set before crushing. e. It is suitable for crushing

Learn More