- [email protected]

- +86-21-63353309

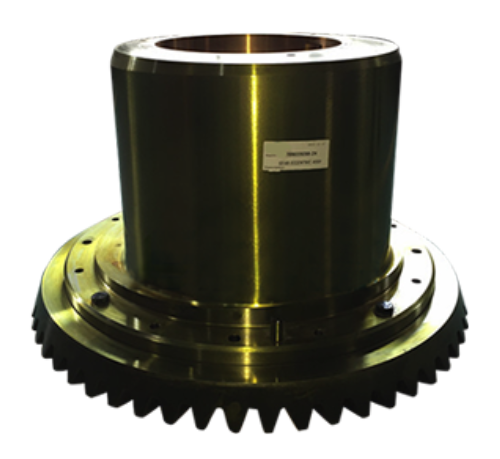

helical gear

helical gear

Helical Gear - NextDayGears.com Helical Gears Fast

A Helical Gear can be used to adjust the rotation angle by 90 degrees when mounted on perpendicular shafts. Its normal gear ratio range is 3:2 to 10:1. Helicals have a larger contact ratio than spur gears. A pair of helical gears has the same helix angle but the helix direction is opposite. If you lay the Helical Ge the table and the teeth

Learn MoreHelical Geared Motor and Worm Gearbox Manufacturer | Decent Engineers

Decent Engineers. Call +91-7942539660 89% Response Rate. SEND EMAIL. Two Stage Helical Gear Motor. Price: ₹ 5,000 / Piece. Get Best Quote. Foot Mounted Helical Geared Motor. Price: ₹ 6,000 / Piece. Get Best Quote.

Learn MoreHelical Gearbox: Working Principles & Application - Linquip

A helical gearbox is technically a spur gear set with a 0° helix angle. For helical types, helix angles mostly run between 15° and 30°. The

Learn MoreHelical Gears - MISUMI

Spur gears used for the power transmission between unparallel shafts. Features: Helical gears have a higher contact ratio than spur gears, resulting in

Learn MoreHelical Gears - McMaster-Carr

Standard helical components have a 21 1/2° helix angle so they only transmit motion in a straight line since the helix angle is so small. Made from alloy steel,

Learn MoreHelical Gears | KHK Gear Manufacturer

Helical gears are one type of cylindrical gears with slanted tooth trace. Compared to spur gears, they have the larger contact ratio and excel in quietness

Learn MoreDesign of Transmission Systems - Helical Gears - Google

The spur gear that has helix teeth (helicoids teeth) is called Helical Gear. Helical gears can transmits force between parallel shafts and non parallel shafts. They are widely used in different

Learn More1126 Helical gear Images, Stock Photos & Vectors

Find Helical gear stock images in HD and millions of other royalty-free stock photos, illustrations and vectors in the Shutterstock collection.

Learn MoreQuality Helical Gear Speed Reducer & Helical Worm Gear

Helical Gear Speed Reducer. Equivalent 380V Helical Gear Speed Reducer 36000N.M. Electric 0.18 To 0.75KW Helical Bevel Gear Reducer 80-750N.M. In Line Coaxial Helical Gear Speed Reducer HT250 R Series. Helical Worm Gear Reducer. S Series Helical Worm Geared Motors 4000N.M. 2.5-360rpm Helical Worm Gear Reducer R Series With Motor

Learn MoreWhat is a helical gear? - Quora

Helical Gear is a type of gear wheel which forms one of the mandatory and significant parts of a Transmission system, which generally is called a Gearbox, of a

Learn MoreHelical Gears | Helical Gear Hob | Helical Gear Set - Koro

Koro manufactures helical gears complete or will cut helical gear teeth on customer supplied blanks. We make helical gears for the following industries: aviation, defense and aerospace instrumentation, commercial, energy, general industry and equipment, healthcare, leisure, musical instrument, power tool, scientific research and transportation. Koro manufactures helical gears

Learn MoreHelical gear Definition & Meaning - Merriam-Webster

The meaning of HELICAL GEAR is a gear wheel having teeth set obliquely to the axis of rotation : screw wheel.

Learn MoreHelical gears: What are they and where are they used?

Helical gears are often the default choice in applications that are suitable for spur gears but have non-parallel shafts. They are also used in

Learn MoreAll About Helical Gears - What They Are and How They Work

Helical gears are power transmission components primarily used to decrease speed and increase torque between rotating shafts. Essentially, they can be split between two groups, those that transmit power between parallel shafts and those that transmit power between non-parallel shafts, commonly referred to as cross-axis gears.

Learn MoreGear - Wikipedia

Double helical gears overcome the problem of axial thrust presented by single helical gears by using a double set of teeth, slanted in

Learn MoreHelical Gears Selection Guide: Types, Features, Applications

Helical gears are cylindrical gears whose teeth are not parallel to the axis of rotation. The teeth are angled and appear as a segment of a helix.

Learn MoreAdvantages and Disadvantages of Helical Gears

Helical gears can be used with both parallel and non-parallel shafts. Because the teeth engage more gradually, helical gears offer smoother gear operation, reducing shock loads and causing less noise and vibration. This makes them ideal for high-speed applications where noise abatement is a requirement.

Learn MorePrecision Helical Gear Manufacturing at Gear Motions

Helical gears have teeth that are set on an angle to the gear axis. The features and benefits are similar to spur gears but can be a better option when

Learn MoreHelical Gears | Helical Gear Hob | Helical Gear Set - Koro Industries

Koro Industries: Helical Gears and Helical Gear Set Manufacturing Capabilities. We manufacture to your specifications. Overall Length (helical gears and shafts) - Up to 14 inches long. Diametral Pitch (helical gears and shafts) -200 - 8 D.P. Pressure Angle (helical gears and shafts) - Nearly any angle that can be produced with a hob.

Learn MoreCustom Helical Gears Manufacturer - PIC Design

Helical Gears. Helical gears have slanted teeth that are cut at an angle to the axis of rotation. This helix angle can be up to 45 degrees and can be left- or right-handed. Compared to spur gears, helical gears are quieter and produce less vibration, so

Learn MoreWhat is double helical gear? - buysch.adamstankandlift.com

What are helical gears? Helical gears are one type of cylindrical gears where the teeth are curved into a helix shape. Compared to spur gears (straight teeth), properly designed helical gears can have a larger total contact ratio which can improve vibration and noise. Badly designed helical gears can be noisier than well designed spur gears.

Learn More