- [email protected]

- +86-21-63353309

gyratory crusher lube system

gyratory crusher lube system

HP500 SPLIT FLANGE 1A32FLB32 | gyratory crusher lube system

PF impact crusher read more It can crush all kinds of coarse, medium and fine materials (granite, limestone, concrete, etc.) with a feed particle size not exceeding 500mm and a compressive strength not exceeding 350MPa. , Energy, cement, chemical, construction and other industries

Learn MoreUS2628788A - Gyratory crusher - Google Patents

B02C2/045 Crushing or disintegrating by gyratory or cone crushers An added object is to provide an improved lubrication system for acrusher of the

Learn Morefr/analyse gyratory crusher gear system.md at main - GitHub

CMS Cepcor system to suit 3' Standard and Shorthead.Manufactured in the United Kingdom.CMS Cepcor lubrication system.Compatible with all 3' cone crushers

Learn MoreGP300 MAIN SHAFT GP300 | gyratory crusher lube system

What is High Manganese Steel Cone Crusher Wear Parts Suit. Check out the new High Manganese Steel Cone Crusher Wear Parts Suit Gp300 Main Shaft Assy from Jiangsu Hyton Mechanical Equipment Co., Ltd.. Here are multi-dimension videos for your reference such as product videos and company videos.

Learn Morelubrication system of cone crusher slideshare

Gyratory Crusher Lube System YouTube. Feb 08, · The lubrication system is comprised of an oil reservoir, pumps, heat exchanger, and protective instrumentation. Its function is to lubricate and cool the crusher moving parts and keep them clean The lubrication of Gyratory crushers may be one of the special problems that the Jaw crusher

Learn MoreCVB2050 RUBBER LINER | gyratory crusher lube system

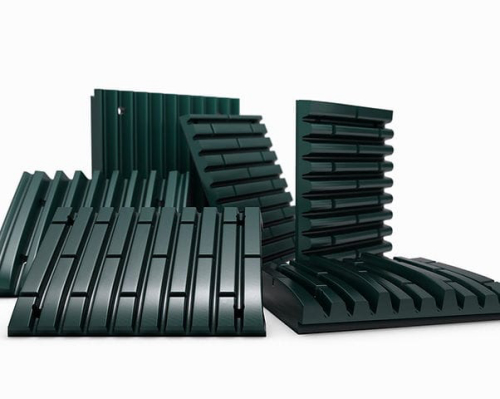

BDI Wear Parts is a dynamically growing company with many years of experiences in production and supply of Crusher wear parts, Crusher spare parts, and Ball mill liners and Forged steel balls. We supply wear parts to the USA, Canada, Europe, Australia and Africa. Gb Th Cat Gen Complet Low Res - Calaméo

Learn MoreGYRATORY-CRUSHERS.pdf - RocketCDN

When the feed to a gyratory crusher is run-of-mine it is normally Efficient lubrication systems are the key to trouble free gyratory crusher operation.

Learn MoreCrusher | IQ Oil Australia

Crusher ; Client: BHP Billiton Iron Ore ; System: Crusher Lube Tanks, Gearbox Primary & Secondary, Gyratory Crusher. ; Oil: 2000L ISO 150 ; ISO Prior to CJC®: 24/22

Learn MoreGrease Lubricating System Used in Different Types of Stone Crusher

Normally, operating an oil-lubricated crusher with contaminated lubricating oil (old, dirty oil) is a common mistake followed by maintenance people. As a thumb rule, operators should use gear lubricants added with extreme pressure additive with a minimum oil viscosity of 22 CST at the bearing operating temperature.

Learn Moregyratory crusher pinion shaft

Gyratory Crusher Lube System Feb 8 How a Gyratory Crusher Lube System Works Certain components in the crusher pinion shaft and bearings pinion and

Learn Moregyratory crusher working G10SEC V-BELT PULLEY SPC 530/8, ECCENTRIC

Gyratory crushers work on the same principle as cone crushers (Figure 4.4(c)). These have a gyratory motion driven by an eccentric wheel. gyratory crusher lube system working. Gyratory Crusher Lube System Gyratory Crusher Animation gyratory crusher working animation Oct 17 working animation of gyratory crusher

Learn MoreCone Crusher Lube Systems | Crusher Mills, Cone Crusher, Jaw

New Cone Crusher Products » Cone Crusher Enhancement Products. We offer following new products to enhance your CS cone crushers: 4 ¼' Cone Crusher. Turbocharge Kit; . Lube

Learn MorePrimary Gyratory Crusher Failure Lubrication System

Lubrication System At Primary Crusher android-hubo.de. Lubrication System At Primary Crusher. Lubrication system at primary crusher minig machine lubrication system at primary crusher 2019-6-6 the lubrication of gyratory crushers may be one of the special problems that the jaw crusher isnt as readily exposed to this crusher because it may be loaded from two

Learn MoreCG800i Gyratory Crushers — SRP

Our Tank Instrument Monitoring System (TIMS) provides real-time monitoring of the crusher lubrication system to ensure it functions optimally. Monitoring the Lubrication system, spider bearing grease system and overpressure system, it ensures oils are at the right flow and temperature, and triggers alarms to protect the crusher.

Learn MoreInstruction Manual for Gyratory Crusher PXZ-1500II

1 Section 1 Safe Operation of Equipment 1.1 Introduction The gyratory crusher of CITIC Heavy Machinery company is mainly used in mines, quarries, metallurgy and other fields. During its process of design and manufacturing, we take full account of the influence

Learn MoreIntroduce The Lubrication System of Gyratory Crusher

Pastebin.com is the number one paste tool since 2002. Pastebin is a website where you can store text online for a set period of time. A self-contained lubricating system of gyratory crusher for operatively lubricating the mounting mechanism and the drive train

Learn More5 30 Replacement Parts SUPERIOR MK II Gyratory Crushers Section 5

LUBRICATION OIL COOLERS SUPERIOR gyratory crusher lubrication systems canbe supplied with either an air-to-oil or a water-to-oil heat exchanger to maintain the oil at the proper operating tem- perature. Air-To-Oil CoolersSUPERIOR gyratory crushers are generally supplied with an air-to-oil type cooler.

Learn MorePDF DESIGNED TO CRUSH SMART BUILT TO MEAN BUSINESS - Mining and ...PDF

These reliable, premium, gyratory crushers are full of smart innovations and connected 24/7 to My Sandvik. Tough crushing together with a complete overview of crusher performance - to maximize uptime and The lubrication system contains a suite of smart alarms and monitoring systems to keep your crushing at maximum efficiency. It monitors

Learn MoreGyratory Crushers - SolidsWiki

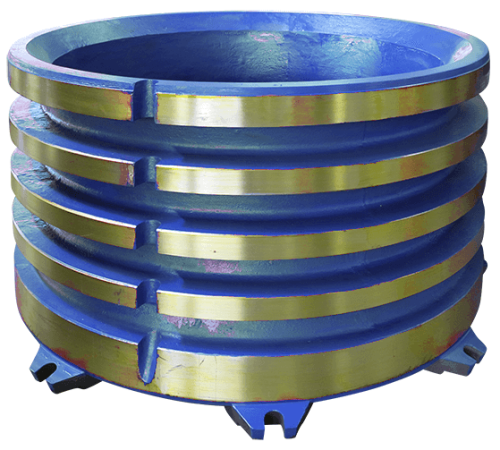

A Gyratory Crusher is a large crushing machinery, using the gyratory sports in casing cone thin oil lubrication system components etc.

Learn MoreFive steps to optimize crusher's lubrication system - Outotec

1. Monitoring of lube oil temperature A lot can be learned about a cone crusher by simply watching the supply oil temperature and comparing it to the return oil temperature. Return oil temperature should be in the range of 60~140ºF (15~60ºC), although ideally in the range of 100~130ºF (38~54ºC).

Learn MoreUS5944265A - Gyratory crusher having self-contained lubrication system

US5944265A US08/786,034 US78603497A US5944265A US 5944265 A US5944265 A US 5944265A US 78603497 A US78603497 A US 78603497A US 5944265 A US5944265 A US 5944265A Authority US Unite

Learn More