- [email protected]

- +86-21-63353309

lip seal vs oil seal

lip seal vs oil seal

Recommendations for Bearing Seals - Timken Company

Rubber O.D. dual lip seal nomenclature. conditions, the section of the shaft being contacted by the seal lip should be hardened to Rockwell C30 minimum. In applications where the shaft may be For the most challenging conditions, oil seals are available in a variety of styles, including multi-lip designs. A standard double-lip design, made

Learn MoreLip Seal - an overview | ScienceDirect Topics

The term interstitial seal is used for seals that allow unrestricted relative motion between the stationary and moving components (i.e. no seal to shaft contact)

Learn MoreGeneral Purpose Clipper Oil Seal (LUP, LPD, LDS, RUP, RPD) - Parker NA

Parker's LUP , LPD, RUP and RPD Clipper® oil seal profiles are general purpose, single lip rotary shaft seals. Their materials of construction - a dense outer case and soft, flexible lip - are concentrically molded as a single unit.

Learn MoreThe Difference of Single Lip And Double Lip Grease Seals

The difference between the single lip and double lip seals is that the double lip grease seal will have two rubber lips that are in contact with the spindle. The double lip grease seals are usually used in marine applications to give a better seal and protect the bearings from the water, which can cause damage to them.

Learn MorePDF Single lip and double lip - Schaeffler GroupPDF

The seal carrier is made from reinforced polyamide (coloured black), while the seal lip area is made from thermoplastic PU elastomer (coloured green). Sealing rings SD are also suitable for use as wipers on shafts undergoing axial motion and allow stroke speeds of up to 3 m/s, depending on the surface quality of the shaft.

Learn MoreTypes of Oil Seals | ERIKS shop NL

The spring on the lip of the oil seal provides support to the lip and prevents the lubricant from leaking outside and also prevents contaminants from entering. The oil seal consists of a metal ring as the inner skeleton which provides the structural stability to the oil seal.

Learn MoreLabyrinth Seals and Lip Seals: An Economic Comparison

As long as a lip seal is operationally effective and has not degraded to the point of shaft wear or elastomer lip wear, it is reasonable to assume that 160 watts of frictional energy are consumed by an average seal. At $0.10/kWh, that equates to $140 per year.

Learn MoreLip seals - Lagersmit

The lubrication film forms a barrier between two media, such as water and oil. Another advantage is that the lip seal and liner do not make contact. This

Learn MoreOil Seals 101 – Part 2 | Global O-Ring and Seal

Standard Sealing LIP Designs · (single lip): This design uses a garter spring and generally seals against internal media in lower pressure

Learn MoreLip Seals & V-rings and their use in the Oil & Gas Sector

In most circumstances, standard lip seals are suitable for oil and gas applications, but when a standard lip seal is not the best option,

Learn MoreMetric Oil Seals, Single & Double Lip Oil Seals in USA | S.S.P

Oil Seal Lubrication. The sealing lip of the oil seal should never be in contact with the shaft. If this were the case, the seal would wear out in a matter of hours. Therefore precaution must be taken that the seal is correctly lubricated prior to fitting. If the seal is not lubricated properly, the seal lip could burn, leading to seal failure

Learn MoreSealing lip design | SKF

The form and design of a sealing lip is based on knowledge gained through research and development activities as well as wide practical experience obtained by SKF in close cooperation with users. The distance between the lip and the seal back face, the strength of the flex section, the angle of the lip ( fig 1) and the tension in the spring are

Learn MoreWhat Are the Differences Between Oil Seal and Mechanical Seal? - Lepu Seal

16/04/ · When it comes to design the difference between the oil seal and the mechanical seal (mechanical seal vs oil seal) is that mechanical seals have three sealing points. Engineers fit the stationary part of the seal to the pump’s housing using a static seal. While they use the use an O ring to seal the rotary portion to the shaft. This makes the

Learn MoreOil Seals, Simmerrings® & Radial Shaft Seals | NewDealSeals

This thin layer of oil performs a barrier and prevents leakage of the oil past the sealing lip. For this reason rubber oil seals are not suitable for dry

Learn MorePDF LUP, LPD, LDS ProfilesPDF

seal lip. The unique, nonmetallic construction will not rust or corrode and forms a gasket-type seal between the equipment housing and the seal outside diameter (OD). Clipper Split Seals are known for being the easiest split seal to install because they do not require a cover plate to keep them in the housing.

Learn MoreLip-Seal vs O-Ring - Restore An Old Car

The o-ring piston seal was designed to alleviate the relaxing lip seals, but the reduced piston to wall clearance inherent with the o-ring design (when installed in a floating piston caliper), eliminates what Duntov said was necessary. The designed-in balance between the lip seal and the piston spring is lost with O-ring pistons (the purpose of

Learn MoreMajor Differences Between Lip Seals and CinchSeal Rotary Shaft Seals

Rotary lip seals maintain a thin layer of lubricant between the "lip" and the shaft. The hydrodynamic action created by the turning shaft causes a pump action that helps hold the seal. The lip makes point contact with the shaft that forms two angles, and it is this contact with the rotating shaft that wears and damages the shaft.

Learn MoreDripless Shaft Seals - Buyer's Gude - Practical Boat Owner

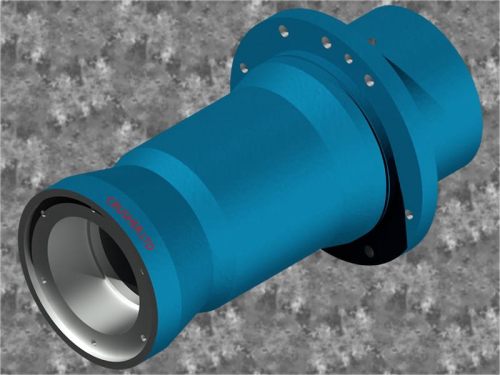

20/11/ · A pressurised cooling water supply is required to lubricate the lip seal and alignment bearing in the seal head. The Sureseal comes with a two-year/2,500 engine hours warranty, and spares kits are available so that its lip seal can be replaced with the boat afloat. (A) Hose cuff length: 51-76mm (B) Overall length: 200-258mm

Learn MoreOil Seal Profiles | Allied Metrics Seals & Fasteners, Inc

TC oil seals feature a dual lip with a garter spring and utilize a rubber cover for improved sealing ability. SA seals, also known as Rotary Shaft Lip Seals, come in a variety of materials. Van seals, also known as radial lip seals, are used in a variety of industries including automotive, consruction, power generation, medical and aerospace.

Learn MoreOil Seal (Lip Seal) Vs. Mechanical Seal: Pros & Cons of Each - Abbey Seals

The purpose of any seal is to protect a joining in a piece of equipment. Seals serve to keep lubrication or other liquids inside and contamination outside of the joint. A lip seal is also known as an oil seal or a rotary shaft seal. Oil seals or rotary shaft seals and mechanical seals are designed for moving parts.

Learn MoreMajor Differences Between Lip Seals and CinchSeal Rotary

The hydrodynamic action created by the turning shaft causes a pump action that helps hold the seal. The lip makes point contact with the shaft that forms two

Learn More