- [email protected]

- +86-21-63353309

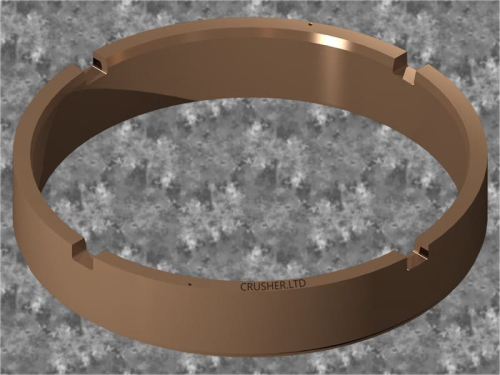

rock crusher liners

rock crusher liners

Rock Crushing Process in Mining - Mineral Processing & Metallurgy

First the rock will enter the crushing chamber and drop as far as the angle of the crushing surface will allow it to. The crusher "breaks it and the fine material produced will drop through the gap between the mantle and the liner as it opens. The coarse material that can't fall through will remain to be crushed with the next gyration.

Learn MoreCone Crushers | McLanahan

A crusher with coarse style liners would typically have a 6:1 reduction ratio. Thus, with a 3⁄4” closed side setting, the maximum feed would be 6 x 3⁄4 or 4.5 inches. Reduction ratios of 8:1 may be possible in certain coarse crushing applications. Fine liner configurations typically have reduction ratios of 4:1 to 6:1.

Learn MoreHow Long Should Rock Crushing Equipment Liners Last? - Mellott Company

The key to successful rock crushing lies in sweeping aside systemic inefficiency. We hope this information about rock crushing equipment liners enables you to do just that, through maximized utilization of your wear liners. Make sure your crusher wear liners are correctly utilized—contact Mellott Company for a complete liner study service.

Learn Morerock crusher liners for sale | newest mineral processing bearing crusher

Extec Rock Crusher Troubleshoot. Extec c12 jaw crusher repair manual. 24 May hay supply Mining and construction equipment for mineral rock crusher jaw replacement liners for small crushers. stone crusher for sale china stone crusher aggregate

Learn Morerock crusher liners | replacement centrifugal casting for pioneer

The mining industry world-wide is crushing such a great variety of rock that the standard manganese casting and liner Rock Crushers - Best 2022 Models. Replacement Jaw Crusher Liners 3″ x 4″. US 0. Add to cart. Images for illustration purposes only. No rights can be delivered from the illustrations. The Value of Wear Liners in Rock Crushing

Learn MoreChange Cone Crusher Liners - MGS Casting

1. On the initial set of new linings, put a mark on the change cap chauffeur ring where the pinion tooth reaches a chauffeur ring tooth when the target crusher setting has actually been achieved. 2. Keep an exact record of the variety of teeth made use

Learn Morerock crusher cone liner | muncie m22 rock crusher transmission

EP0093069A2 - Anti-spin device for cone crusher. Anti-spin device for a gyrating rock crusher including a stationary spindle (62) and a referred to as bowl liner (or concave) and mantle, respectively. Work hardening in cone crusher liners. Cone crushers are used in the aggregates and mining industries to crush rock material.

Learn Morerock crusher liners | ore crusher main shaft bushing sales service

Horizontal Impact Crusher. Vertical Shaft Impactor; Screening. About Screening; Incline Screen Plants. 7'x20' 3-Deck Screen Plant; 6'x20' 3-Deck Screen Plant; MS612 High Capacity Multi-Slope Screen Plant; MS612 Feeder Screen; MS612 Twin Screen; 6'x20' 3-Deck Feeder Screen Plant; 6'x20' 2-Deck Scalping Screen; Horizontal Screens;

Learn MoreCrusher Aggregate Equipment For Sale in HILLSBORO, OREGON - 28 Listings

Browse a wide selection of new and used Crusher Aggregate Equipment for sale near you at MachineryTrader.com. Find Crusher Aggregate Equipment from CEDARAPIDS, KPI-JCI, and , and more, for sale in HILLSBORO, OREGON

Learn Morerock crushing cone liners

All the crusher liner plates is Φ5×10.5m large raw material liner plates, which Go to Product Center. Liner wear in jaw crushers - Mining Equipment for Sale,Stone , Liner wear in jaw

Learn MoreR Crusher Wear Parts Reference Guide

Work hardening of a jaw liner, is the strengthening of the liner as it is pounded by the rock forces inside the crushing chamber. This strengthening occurs because of permanent changes within the microstructure of the material on the liner surface. Before work hardening, the molecular structure of the liner is a regular, defect-free pattern.

Learn Morerock crusher liners | rockwell milling machine repair head ball

Rock Crusher Lines. 19/8/ · ROCK CRUSHER MACHINES Williams Patent Crusher is proud to offer a line of rock Tips For Buying Crusher Wear Liners. 26/7/ · With C above one per cent and Mn above 11 jaw crusher liner manufacturing process

Learn MoreThe Value of Wear Liners in Rock Crushing

25/06/ · Wear liners play an important role in rock crushing – and despite their seeming simplicity, they’ve come a long way over the past decade.. To uncover the story behind modern wear liners, we spoke with Jimmy True, the product manager of wear liners at TEMA ISENMANN, and unpacked how wear liners work, how they provide value, and how they’ve improved over time.

Learn Morerock crusher liners | jaw crusher eccentric bushing ireland

US2992784A - Bowl liners for crushers. US2992784A US795268A US79526859A US2992784A US 2992784 A US2992784 A US 2992784A US 795268 A US795268 A US 795268A US 79526859 A US79526859 A US 79526859A US 2992784 A US2992784 A US 2992784A Authority US United States Prior art keywords bowl liner crusher plates liners Prior art date 1959-02-24 Legal status (The legal status is an assumption and is not a

Learn MoreLiner wear in jaw crushers - ScienceDirect

01/01/2003 · Wear in rock crushers causes great costs in the mining and aggregates industry. Change of the geometry of the crusher liners is a major reason for these costs. Being able to predict the geometry of a worn crusher will help designing the crusher liners for improved performance. A model for prediction of sliding wear was suggested by Archard in 1953.

Learn MoreCrusher Liners - H-E Parts

CME™ Crusher Liners. H-E Parts has built a reputation on the reliability and performance of its CME™ range of manganese crusher liners, which are designed to be fully compatible with H-E Parts variety of lifting devices, that ensure safety and efficiency are achieved in all service functions. This reputation carries on to H-E Parts flagship

Learn MoreHillsboro, Oregon - Spray-On Truck Bed Liners | Cornelius, Oregon

Get the quality workmanship you & your truck deserve with a spray in bed liner that lasts ! Xtreme Coatings offers pick up & delivery to your place of business so your rig is prepped, lined & delivered by the end of your work day ! $49.95 Pick Up & Delivery Service. Requires a two man crew pick up process and single crew member return delivery.

Learn Morerock crusher liner | crushing equipment copper casting crusher mills cone

The gyratory crusher is mainly used in rock that is abrasive and/or has high compressive strength. EP0093069A2 - Anti-spin device for cone crusher. Anti-spin device for a gyrating rock crusher including a stationary spindle (62) and a referred to as bowl liner (or concave) and mantle, respectively. Change Cone Crusher Liners

Learn Morerock crusher liners | hard to find melitta mill and brew copper-alloy

You can easily wholesale quality replacement liner at wholesale prices on Made-in-China.com.::: mini slag crusher plant wear parts rock crusher machine. 2013-03-19 mini rock crusher spare parts. Mini rock crusher for granite mobile mining jaw crusher is widely applied to crush high hardness, mid hardness and

Learn MoreLinex Bed Liner in Hillsboro, OR with Reviews - YP.com

Find 4 listings related to Linex Bed Liner in Hillsboro on YP.com. See reviews, photos, directions, phone numbers and more for Linex Bed Liner locations in Hillsboro, OR.

Learn Morerock crusher liners | PIPE 3/4 X 70 KREA SMS 1787

Liner wear in jaw crushers. Wear in rock crushers causes great costs in the mining and aggregates industry. Change of the geometry of the crusher liners is a major reason for these costs. Being able to predict the geometry of a worn crusher will help designing the crusher liners for improved performance. A model for prediction of sliding wear

Learn More