- [email protected]

- +86-21-63353309

grate cooler design

grate cooler design

Grate cooler control method and apparatus - Google Patents

Horizontal and inclined grate coolers are usually designed for cooling clinker from rotary kilns in cement plants. The cooler is normally positioned below

Learn MoreCement Kilns: Rotary Coolers

The standard design coolers shown above were installed at Kent in 1949 to replace the original (1922) concentric coolers. On some smaller kilns, such as Wouldham 7 & 8, the concentric coolers were simply removed, and the kilns run with no cooling at all. A tentative list of the concentric cooler installations is as follows:

Learn MoreEP0525380A1 - Grate cooler - Google Patents

The invention relates to a grate cooler, in which the drive device is surrounded by a drive housing, the inner space of which is sealed in an airtight manner in relation to the atmosphere, but on the other hand has a pressure-equalisation connection to the inner space of the cooler housing. Such a grate cooler is characterised by considerably reduced expenditure for sealing the cooler

Learn MoreOffice Water Coolers Hillsboro

Hillsboro Water Cooler Systems. Choose from the largeest selection of office water dispensers in Hillsboro We provide low priced water coolers and bottleless water machines all over the state of Hillsboro from top brands of bottleless point of use water machines like Brio, Oasis water coolers, Atlantis bottleless machines, Kenmore, G3 and Clover water cooler models.

Learn MoreHeat Exchange Modeling of a Grate Clinker Cooler and

The concept of the exergy analysis is applied to a grate cooler of a cement production facility. design of the cooling process.

Learn MoreGrate Cooler – Clinker Cooler | AGICO Grate Cooler In Cement Plant

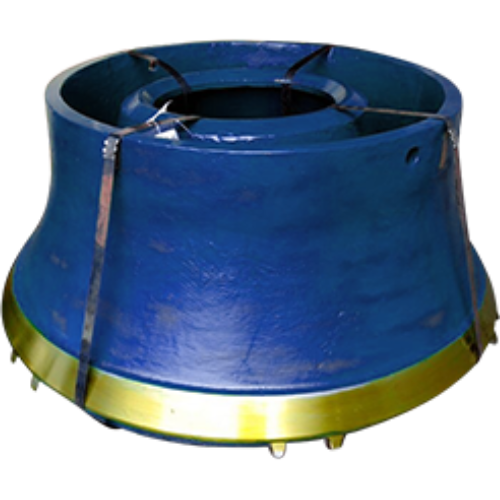

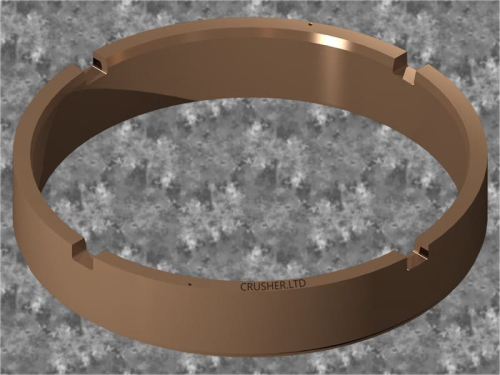

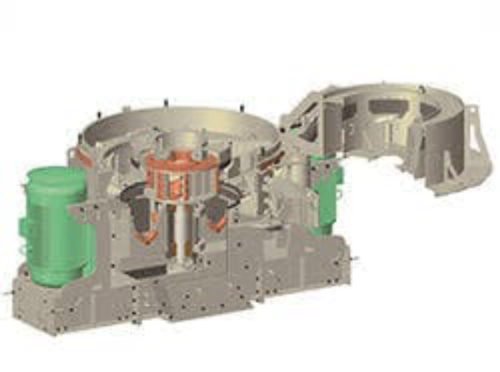

Grate cooler consists of upper case, lower case, lower frame, grate bed, hydraulic transmission device, grate bed support device, clinker crusher, automatic lubrication device, and cooling fan.

Learn Moremodelling of clinker cooler and evaluation of its performance

The design model was scaled down to a ratio 25:1, that is, existing cooler twenty-five (25) and model (Test rig) one (1). The scaling down was based on

Learn MoreMaintenance Of Under Grate Pressure in Grate ... - ijareeie

ABSTRACT: A design of Internal Model Control based PID controller for maintaining the under grate pressure of a grate cooler used in cement plants is

Learn MoreClinker Cooler Unit - FONS Teknoloji

Fons Delta Cooler has been designed in a very smart and compact way; with this compact design, it can respond to the needs of each cement plant separately.

Learn Moreperformance evaluation of a grate cooler in a cement ... - IJSEAS

This study revealed that the grate cooler efficiency estimated through heat consumption balances conformed to the designed standard.

Learn MoreOptimization Design of the Grate Cooler Based on the Power

As an important process during the cement production, grate cooler plays significance roles on clinker cooling and waste heat recovery.

Learn MoreClinker Cooler, Cement Cooler, Grate Cooler | Clinker Production

The traditional grate cooler can be divided into rotary cooler, vibrating clinker cooler and push clinker cooler. The grate bed is the core part of grate cooler. The push type grate plate is made up of fixed grate plate and moved grate plate by radial arrangement. Working principle of clinker cooler The grate cooler is a type of quench cooler.

Learn MoreRotary coolers - for optimised material processing

It too can handle a large range of materials at high temperatures and can be supplied in a hybrid design in order to suit smaller plants without compromising on performance. Unax Cooler Compared to past grate cooler designs, this planetary cooler improves on durability, reliability and simplicity. Despite the Unax Cooler and rotary coolers

Learn MoreMulti-objective optimization design of air distribution of grate cooler

Grate cooler plays a very important role in cement production line whose main functions are quenching high temperature clinker and redistributing the exhaust hot air as shown in Fig. 1 (a). Increasing clinker cooling efficiency has great effects on decreasing power consumption of cooling fans and improving quality of clinker.

Learn Moregrate cooler Latest Research Papers | ScienceGate

Find the latest published documents for grate cooler, Related hot topics, top authors, the most cited documents, and related journals

Learn MoreD9.2 Analysis of oxyfuel clinker cooler operational performance

performance (efficiency), as well as the potential impacts of CO2–rich cooling gas on clinker quality. The oxyfuel clinker cooler prototype was designed

Learn MoreGrate kiln pelletizing plant - Outotec

Benefits Grate Kiln design allows for a lower bed depth compared to a straight grate, resulting in more uniform temperature profile, a lower pressure drop, and less power consumption. Grate Kiln systems consist of three major pieces of equipment. Process overview Grate Kiln systems consist of three major pieces of equipment.

Learn MoreEP0473885A1 - Grate cooler - Google Patents

The aim of the invention is to design a grate cooler in such a manner that the device used to support the swing frame (1) on the stationary abutment (2) can be manufactured simply and is

Learn MoreCooler Options | World Cement

Ask any cement plant manager about the clinker cooler in his plant, The new erection concept, which utilises a modular design,

Learn MoreGrate Cooler - INFINITY FOR CEMENT EQUIPMENT

This design delivers high degree of utilization and minimize overhaul maintenance costs due to eliminating

Learn More