- [email protected]

- +86-21-63353309

sag mill liners

sag mill liners

SAG Mill Distributor Archives - Page 4 of 4 - NCP International

NCP International supplies new and refurbished grinding mills, SAG mills, We supply competitively priced new mill liners, as well as new Chromoly and

Learn MorePDF Continuous improvement in SAG mill liner design using new technologiesPDF

An industrial case study is presented of a 38' diameter SAG mill, which was experiencing challenges associated to liner breakage and low efficiency with the old liner design. Through a

Learn MoreWhat's the Difference Between SAG Mill and Ball Mill

The biggest characteristic of the sag mill is that the crushing ratio is large. The particle size of the materials to be ground is 300 ~ 400mm, sometimes even larger, and the minimum particle size of the materials to be discharged can reach 0.1 mm. The calculation shows that the crushing ratio can reach 3000 ~ 4000, while the ball mill's

Learn MoreSAG Mill Liners Breakage - Grinding & Classification Circuits

After a brief survey of SAG mill operation, CDI can tell whether we can guarantee to: Improve ore throughput (>10%), Liner shell life increase (>20%), Reduce kW-hours/ton for the liner life cycle to designate P80 vs. existing system. Eliminate liner breakage This survey is at no cost to you. S Standartenfurer 7 years ago Like

Learn MoreContinuous improvement in SAG mill liner design using new

An industrial case study is presented of a 38’ diameter SAG mill, which was experiencing challenges associated to liner breakage and low efficiency with the old liner design. Through a

Learn MoreMill liners: grinding out a legacy - Mining Technology

Typically, steel liners are used in aggressive AG/SAG Mill and ROD Mill applications, as rubber will not last on its own. Trelleborg does offer

Learn MoreThe design and evolution of SAG mill liner trails - Hatch

Development of SAG liners has always been of considerable interest to mill operators as liners significantly affect plant performance (throughput,

Learn MoreSAG Mill Liner - Casteel Foundry

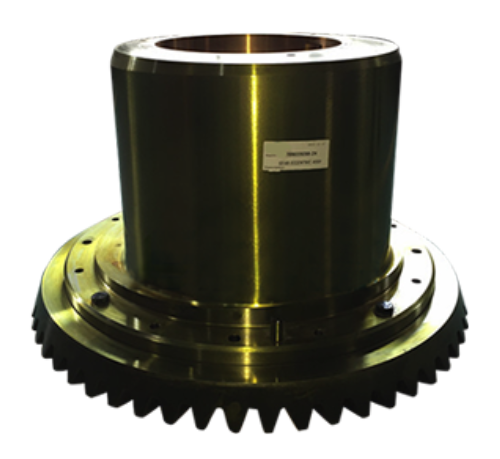

AG /SAG Mill liners is divided into medium Cr-Mo liner plate (A kind of casting steel with the chromium content at 4-6%, the carbon content at 0.4-0.8%)and low Cr-Mo Liner plate (A kind of casting steel with the chromium content at 1.2-2.5%, the carbon content at 0.3-0.6%). Its distinctive feature is to adopt multivariate alloy design.

Learn MoreLeaner and Meaner SAG Mills | Unicast Wear Parts

Among the new innovations that are improving the milling process is a condition monitoring technology that tracks SAG mill liners and

Learn MoreSag Co LLC · 1979 Se 74th Ave, Hillsboro, OR 97123

SAG CO LLC (Registry# 187452496) is a business registered with Oregon Secretary of State, Corporation Division. The business registry date is September 27, 2021.

Learn MoreGrate Liners at Discharge End for SAG Mills EB17014

Quality SAG Mill Liner suppliers provide Grate Liners at Discharge End for SAG Mills EB17014 -Eternal Bliss Alloy Casting & Forging Co., Ltd. from China. Sign In | Join Free | My qualitydress.com: For Buyers. SAG Mill Liner: Place of Origin: China: Brand Name: Eternal Bliss: Certification: ISO9001- : Model Number: EB17014: MOQ: 1 piece

Learn MoreMill liner solutions

options — mill liners offer industry leading wear protection for your SAG and ball mills. And, by incorporating unique geometric.

Learn MoreThe Selection and Design of Mill Liners - MillTraj

ABSTRACT. Dramatic shortcomings of mill liner designs, especially of large SAG mills, - such as rapid failure and even mill shell damage arising from

Learn MorePDF) Understanding the effects of liner we SAG mill

PDF | On Sep 7, , Paul Toor and others published Understanding the effects of liner we SAG mill performance | Find, read and cite

Learn MoreSAG Mill Liners for Discharge Grate - EB Castworld

SAG Mill Liners for Discharge Grate Special Features: The material of SAG mill liner castings are low C or high C Cr-Mo Alloy steel,which depends on the specific working condition of the SAG mill. The hardness of AS2074 L2B is HB310-HB380. We can make big size SAG mill liner castings with Sodium Silicate Sand Process & Resin Sand Process.

Learn MoreSAG mill liner selection to maximise productivity - Ausenco

With an increasing treatment of complex ore bodies with variable competencies, SAG mill liners and discharge systems are proving to be crucial components

Learn MoreSAG mill increases productivity, reduces unscheduled

SAG mill increases productivity, reduces unscheduled shutdowns via proper liner bolt installation, lubrication. Case study: MOLYKOTE® P-74 Assembly Paste

Learn MorePDF Semi-autogenous grinding (SAG) mill liner design and developmentPDF

with increasing mill speed as shell lifters wear, is a promising current development in shell liner design and SAG mill opera-tion providing the potential for lower energy consumption, increased throughput, and start-up "on-grind" with new lifters (Veloo et al., 2006b). Highly worn shell lifters can still deliver adequate (though

Learn MoreSteel-casted mill liners for mining - Fundiciones Estanda

Metallic liners for all kind of SAG mills, AG, ball mills and rod mills present in the grinding processes of minerals. Liners profile design upon client´s

Learn MoreKey considerations when selecting a mill lining system

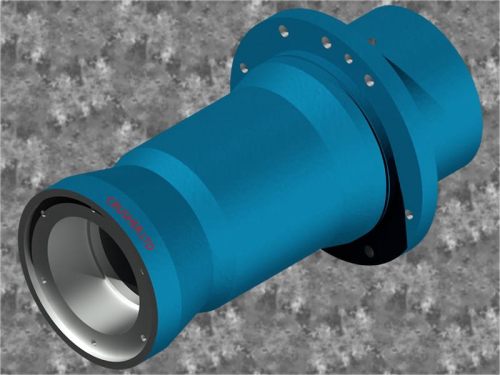

SAG and ball mills grind material through different actions and are usually applied in different stages of the process. SAG mills usually have a

Learn MoreChina AG / SAG Mill Liners Inner Pulp Lifter Liners Cr-Mo Steel Wearing

China AG / SAG Mill Liners Inner Pulp Lifter Liners Cr-Mo Steel Wearing Spare Parts, Find details about China Wear Resistant Castings from AG / SAG Mill Liners Inner Pulp Lifter Liners Cr-Mo Steel Wearing Spare Parts - Eternal Bliss Alloy Casting & Forging Co.,LTD..

Learn More