- [email protected]

- +86-21-63353309

crushing efficiency in size reduction

crushing efficiency in size reduction

crushing efficiency of a crusher

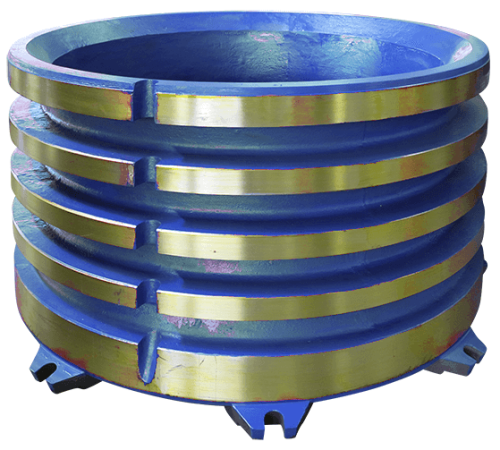

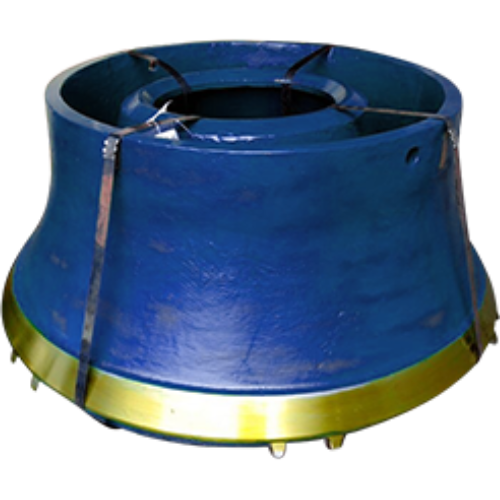

crushing efficiency of a crusher high efficiency cone crusher mantle germe edu.org ® HP Series™ cone crushers PFS Impact Crusher vipeakgroup.com Assessing the ene

Learn MoreCrushing Efficiency Of Size Reduction Equipment - Crusher Mills

06-CRUSHER-Effect of Blasting on Crushing Efficiency and Energy. Crushing and Grinding Efficiency and Energy and that an associated reduction in P80 size to 30 cm in the and the crushing and grinding equipment .

Learn MoreCrushing Efficiency Factors - Mineral Processing & Metallurgy

The results are shown in Figure 3-17. It is seen that for a reduction ratio of 1.32, the relative efficiency of crushing a multi-layer of particles is 72%. Note that crushing ratios in a ball mill are not well defined, but are believed to range up to 1.5 or even 2.0.

Learn MoreSize Reduction Operation - an overview | ScienceDirect Topics

Cutting and chopping are size reduction operations based on shearing through the use of sharp-edged moving elements (knives, blades). The term 'cutting' is usually reserved for operations resulting in particles with fairly regular geometric forms (cubes, juliennes, slices), while the term 'chopping' is applied mainly to random cutting.

Learn MoreUnit Operations - Size Reduction Flashcards | Quizlet

work required in crushing is proportional to the new surface created Rittinger's Crushing Law states that calls for relatively less energy for the smaller product particle than does the Rittinger Law Bond Crushing Law gross energy (kWh/ton of feed) needed to reduce very large feed to such a size that 80% of the product passes a 100 micron screen

Learn MorePDF SIZE REDUCTION - akahl.comPDF

size reduction for the biomass industry are, for example, higher energy efficiency, more eco-nomical drying, and improved pelleting. AMANDUS KAHL supplies four different size reduction machines, which are used in various industries, namely the pan grinder mill, the crushing roller mill, the crumbler and the ham-mer mill.

Learn MoreSize Reduction and Energy Requirement - ScienceDirect

The mechanisms of size reduction during crushing and grinding are different. The chief difference is that in crushing operations the size reduction is more by compression and impact and less by attrition while in grinding; the forces of attrition are much greater. This efficiency factor is only used when R is outside the range R RO ± 2. 7

Learn MorePDF SIZE REDUCTION - Universiti Teknologi MalaysiaPDF

SIZE REDUCTION 2. require a small power input per unit of product 1. have a large capacity •An ideal crusher would: 3. yield a product of the single size distribution desired •cost of power is a major expense in size reduction equipment, so the factors that control this cost are important where e S = surface energy per unit area C e S (A wb A

Learn MorePrinciples Of Size Reduction By Crushing

Principles Of Size Reduction By Crushing. A material consisting originally of 20 mm particle crushed to an average size of 5 mm and required 30 kjkg for this size reduction determine the energy required to crush the material from 20 mm to 3 mm assuming a rittingers law b kicks law and c bonds law solution a applying rittingers law as expressed by equation 410.

Learn MoreSize Reduction | PDF | Mill (Grinding) | Physical Sciences - Scribd

Knife cutters • Dicers • slitters Jaw Crusher • The swinging jaw makes an angle of 200 to 300 with the fixed jaw • Feed opening may be up to 2.5m x 2.0m • processing up to 1200 t/h • Product size is adjusted by adjusting the gap size

Learn MoreShredder & Crusher Systems for Size Reduction - RecyclingInside

10/7 · The Shredder Unit can be made with crusher and separator units according to customer demand. It is possible to reduce the grain size up to 1 mm if the shredder designed with the crusher. PCBs, which are electronic waste, is approximately 40×40 cm in size. They feed directly into the shredder and the resulting product size is in the range of 25

Learn MoreTips to maximize crushing efficiency - Pit & Quarry

5/13 · Efficiency can be defined by the ratio of a machine’s work to the energy supplied to the machine. To apply what this means to your crusher, operations produce the exact sizes in

Learn MoreCHAPTER 3 Size Reduction and Size Separation

Example-II: The absorptive power of charcoal and kaolin increases after size reduction due to increase in surface area. 2. Size reduction produces particles in narrow size range. Mixing of powders with narrow size range is easier. 3. Pharmaceutical suspensions

Learn MoreLarge Size Reduction Crusher

Stone jaw crusher: high size reduction ratio Min. Order: 1 Set FOB Price: US $1-9999999 / Set Stone Jaw Crusher: 1.Big reduction ratio Jaw stone crusher; size reduction ratio of a crusher calculated the size reduction ratio of crusher,method

Learn MoreCrusher Efficiency Determination | Crusher Mills, Cone Crusher, Jaw Crushers

Ore size reduction circuits e.g. crusher efficiency checks. Determination of up to 6 different material size fractions via a multi- tier vibrating screen. critical speed formula for ball mill – ore mineral crushers

Learn MoreCrushing Efficiency Of Size Reduction Equipment

crusher performance in reduction ratio – beltconveyers.net. Mining Equipment; Crushing Plant; Spare Parts; . Crusher Type Size, mm Reduction Ratio Average 7:1 high reduction

Learn MoreCrushing Efficiency Calculator | Calculate Crushing Efficiency

To use this online calculator for Crushing Efficiency, enter Surface Energy per Unit Area (es), Area of Product (Ab), Area of Feed (Aa) & Energy Absorbed by Material (Wh) and hit the calculate button. Here is how the Crushing Efficiency calculation can be explained with given input values -> 73.97727 = (17.5* (100-7))/22.

Learn MoreHP4 NUT G4121008 crushing efficiency in size reduction

HP4 NUT G4121008 crushing efficiency of jaw crusher flange, parted sae3000 4" supplier outer bushing sbm jaw crusher astm a182. Size of rear axle nut ? Jul 07, · For those of you who have time to shop, I bought this socket from Sears on-line Part # 00994221000 - .99 -. NHT Axle Nut 1/2" Drive 34mm (Socket) Click to expand

Learn MoreCHAPTER 20: SIZE REDUCTION – EQUIPMENT FOR SIZE

D f / D p – Size reduction ratio • Coarse grinding has RRs below 8:1 • Fine grinding can exceed 100:1 • Grinding of coarse particles in which the increase in surface area per unit mass is

Learn MoreHow Material Size Directly Affects Size Reduction Energy

Rittinger's Law — The energy required for reduction in particle size of a solid is directly proportional to the increase in surface area. E = K R f c (1/L 2 - 1/L 1) Kick's Law — The amount of energy required to crush a given quantity of material to a specified fraction of its original size is the same, regardless of the original size.

Learn More