- [email protected]

- +86-21-63353309

parametrization procedure for jaw crusher tooth plates

parametrization procedure for jaw crusher tooth plates

Crusher Close Side Settings - 911 Metallurgist

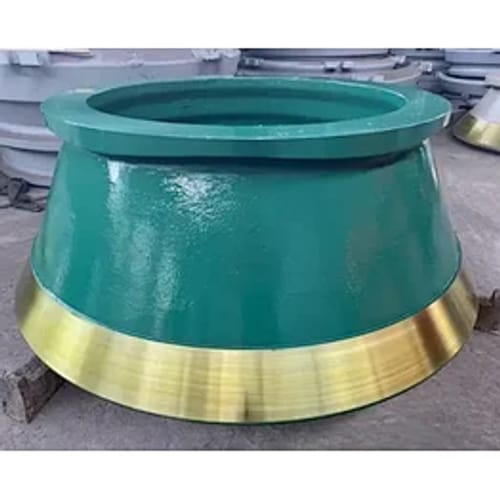

In the standard gyratory crusher this is accomplished very simply by increasing the thickness of the concaves at the top, and tapering them down

Learn Moreparametrization procedure for jaw crusher tooth plates | jaw crusher

parametrization procedure for jaw crusher tooth plates | simons cone crusher 425 pin bushing +86-21-51393804. Black Jaw Crusher Teeth Plate, Rs 45000 /piece Ajit Stone Crusher. Crusher Jaw Plate. ₹ 70 / Kg. By Preet Tradelink Talod Road, Talod, Gujarat. In order to cater the variegated demands of our clients, we are offering an excellent

Learn MoreEvaluating the Impacts of Jaw Crusher Design Parameters by

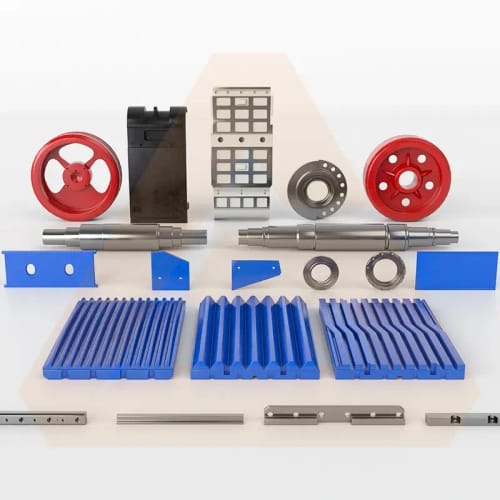

jaw crusher by a simpler and faster way, simulation. The process of size and moving jaw plates, measured from a tooth top on one jaw.

Learn MoreJaw Crusher: Mineral process & Sand production | Sotecma

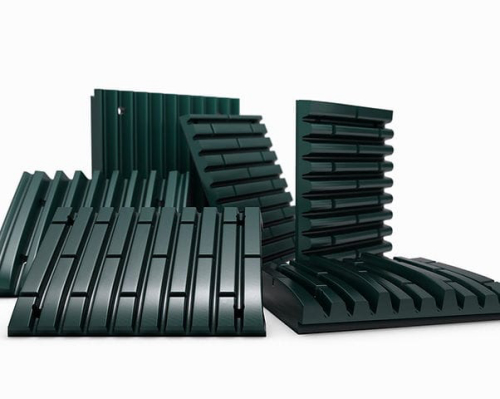

Both the mobile and fixed jaws have a removable and reversible anti-wear cast iron plate. Toothed design to improve the efficiency of the crushing. The mobile

Learn MoreCrusher Wear Parts Reference Guide - Corporation

Welcome to the First Edition of the Finlay Crusher Wear Parts Reference On all other jaw plates in the range the half tooth is on the swing jaw so.

Learn Moreparametrization procedure for jaw crusher tooth plates tm100 crusher parts

parametrization procedure for jaw crusher tooth plates TK11422V WEAR PLATE INST Safe Exam Browser / SVN / [r3221] /tags/win/1.8.2. Download this file. 56054 lines (56053 with data), 609.7 kB. What is the reason for the fast wear of jaw crusher tooth plate. Jaw crusher is commonly known as jaw crusher, also known as tiger mouth.

Learn MoreComputer Aided Design and Analysis of Swing Jaw Plate of

The jaw crusher is primarily a compression crusher while the others operate primarily by the application of impact. Crushing is the process of reducing the size

Learn MoreHow to get the most wear life out of your rotatable one-piece

When the wearing of the jaw plates is severe, the crusher performance is not ideal, because the empty spaces between the teeth are reduced,

Learn MoreCrushing, screening, feeding and plant solutions

Traylor and Fuller-Traylor gyratory crushers of the early available from to meet any process requirement. Swing Jaw Wear Plate.

Learn Moreparametrization procedure for jaw crusher tooth plates | kueken crusher

6. installation of tooth plate. jaw crusher tooth plate is directly for crushing ore parts. its structure is simple, but because of frequent contact with the ore, tooth plate is the crusher wear quickly. so it is often needed to replace the parts. there are two kinds of cross-section structures shape of the tooth plate, the smooth surface.

Learn MoreAchieve optimal production by choosing the right jaw profile

For feed material with fines, a jaw profile with well-spaced teeth that let fines flow through is ideal. For example, coarse corrugated jaws are

Learn MoreC series jaw crushers - Wear parts application guide

Rotate a second time when the tooth pro- file at the bottom of the jaw die is complete- ly worn. This procedure will allow for good work hardening of the

Learn Moreparametrization procedure for jaw crusher tooth plates - Andrzej Chodacki

Rotating one-piece jaw crusher plates Fixed jaw plate - use until wear of about 30% occurs in the lower area and make the first turn. Make the second turn when wear from 90% to 100% occurs in this new lower area. Conclude by using the remaining 30% of the life cycle of this extremity.

Learn Moreparametrization procedure for jaw crusher tooth plates | G10SEC CNNCTN

Cross support Cast steel rear wall. double toggle jaw crusher gold ore crusher from madagascar. 5 Types of Jaw (Orthognathic) Surgery: Costs & Recovery. Dec 03, · Then they attach a small plastic wafer to the teeth to help align the upper jaw. The jaw is fixed in place with titanium screws and metal plates. Upper jaw surgery can correct an overbite, crossbite, and open bite. 2. Mandibular Osteotomy (Lower Jaw) Mandibular osteotomy surgery, or lower jaw surgery, corrects a severely

Learn MoreAccessories of Jaw Crusher - The Nile Machinery

When one end is worn, it can be used in an adjustable direction. The movable toothed plate and fixed toothed plate are the main land for stone crushing. The

Learn Moreparametrization procedure for jaw crusher tooth plates | crusher

Rotating one-piece jaw crusher plates Fixed jaw plate - use until wear of about 30% occurs in the lower area and make the first turn. Make the second turn when wear from 90% to 100% occurs in this new lower area. Conclude by using the remaining 30% of the life cycle of this extremity. jaw mantle concave spare parts crusher At The Best .com

Learn Moreparametrization procedure for jaw crusher tooth plates some inner

parametrization procedure for jaw crusher tooth plates xxnx hot selling impact crusher spare main frame bushing 8 Pros and Cons of Dental Plates. The Pros of Dental Plates. Natural Look. One of the biggest positives of dental plates is that they are natural looking. This means that you no longer have to be self-conscious about your smile.

Learn Moreparametrization procedure for jaw crusher tooth plates | barmac spare

Jaw plates [jaw dies], cheek plates, toggles, and toggle seats. Design and Analysis of Reciprocating Screw for Injection. Parametrization procedure for jaw crusher tooth plates . June · Gornyi Zhurnal. A. D. Kolga; E. Yu. Degodya; D. M. Aybashev; K. Yu. Habarov; From the analysis of operation of jaw crushers

Learn MoreDeepak Project On Jaw Crusher | PDF - Scribd

Optimum Design and Analysis of Swinging Jaw Plate · 1. Larger, rough, blocky as well as sticky rock or ore lumps can be crushed. · 2. Reinforcement of the

Learn MoreJAW CRUSHER SERIES

The nip angle is the angle between the fixed and moving jaw plates. Our CJ crushers have an optimum nip angle in the 16-23 degree range.

Learn MoreCrushing and Screening Handbook - AusIMM

Quarry Process + Process Integration and Optimization (PIO). 2. Feeders. 3. Crushing Equipment. 3. C-Series Jaw Crushers. 3. Superior MK-II Primary Gyratory

Learn More