- [email protected]

- +86-21-63353309

jaw crusher mounting

jaw crusher mounting

Jaw Crushers Mounting Bearingsl

A method for mounting a jaw die plate of a jaw crusher detachably against a front end wall of the crusher by means of a fastening device operated from outside a side wall of the crusher. The die plate is secured in its place by means of friction between the fastening device and a counter surface of the front end wall and friction between the

Learn MoreCrusher Aggregate Equipment For Sale in HILLSBORO, OREGON - 28 Listings

Browse a wide selection of new and used Crusher Aggregate Equipment for sale near you at MachineryTrader.com. Find Crusher Aggregate Equipment from CEDARAPIDS, KPI-JCI, and , and more, for sale in HILLSBORO, OREGON

Learn MoreJaw crusher – Crushing and Screening service provider

The frame consists of two side plates of rolled steel, plus hollow castings at front frame end and moving jaw which give a high rigidity/weight ratio. Large-radius transition areas reduce stress concentrations and welds are positioned in low-stress areas. The advantage of a welded frame is that it is equally strong in

Learn MorePDF Engineered for the toughest feed materials ® C Series™ jaw crushersPDF

C Series jaw crushers have a strong pinned and bolted, non-welded frame construction and the highest power ratings in each size class, which brings benefits Mounting the crusher does not require anchor bolts. This is due to our unique solution where the crusher is standing on its own weight, and vibrations are absorbed by

Learn MoreJaw Crusher – Conmix Crusher

Jaw Crusher is consists of many parts, like eccentric draft, frame, large belt wheel mobile jaw crusher, flying wheel, toggle jaw plates, gap adjustment screw and so on. The main function of Jaw Crusher is to crush large rocks into smaller rocks, gravel, rock dust and gravel to satisfy different requirement for the products.

Learn MorePrimary Jaw Crushers - Moore Watson Ltd

Jaw Crusher Primary Jaw Crusher Secondary Jaw Crusher Tertiary Jaw Crusher Mobile crusher Skid Mounted Jaw Crusher.

Learn MorePe400x600 Jaw Crusher Mounting Bearing Model

Pe400x600 Jaw Crusher Mounting Bearing Model. Home / Pe400x600 Jaw Crusher Mounting Bearing Model; 400x600 Mining Jaw Breaker Price Pe 400 600 Jaw Stone . Jaw Crusher Used in Differente Construction Material Making Plant PE400X600. 2. Product introduction. The jaw crusher is a curved crushing type. Its working

Learn MoreJaw crusher C120 - Thomasnet

The crusher is mounted without bolts between crusher and structure using mounting pads, which absorb the dynamic forces thus reducing the dynamic loads trans-.

Learn MoreUsed Jaw Crushers for Sale | Surplus Record

Used 15.74" Merz Jaw Crusher, Model BB250/400, approximately 400mm (15.74") wide x 250mm (9.84") deep feed opening, 150mm more View Details Contact Seller Request Price Expand

Learn MoreRaJAWline Jaw Contouring - Style Aesthetics by RajaniMD

Style Aesthetics by RajaniMD Portland's Premiere MedSPA Botox - Lip Filler - CoolSculpting 1125 NW 9th Avenue, Suite 110 Portland, Oregon 97209 CALL 503.303.8313

Learn Moreinstallation of jaw crusher machine

Jaw Crusher Installation Operation – Free Articles Directory Jaw Crusher is generally installed above the concrete foundation. Given the weight of a larger

Learn MoreUS10549283B2 - Jaw crusher retraction assembly - Google

a jaw mounting assembly arranged to enable the second movable jaw to oscillate back and forth relative to the first jaw, wherein the jaw mounting assembly includes a jaw crusher retraction

Learn MoreEAGLE 18 X 36 JAW CRUSHER MOUNTED ON STAND

EAGLE 18 X 36 JAW CRUSHER MOUNTED ON STAND. Item #: 1-1167; Portable: No; Specifications: 75HP WESTINGHOUSE ELECTRIC MOTOR, 36" DISCHARGE CONVEYOR, MOVEABLE JAW

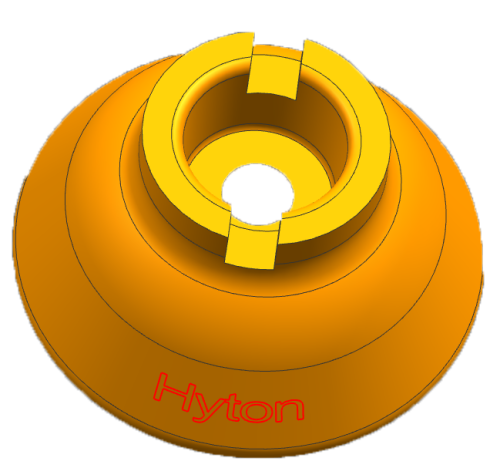

Learn MoreCone & Jaw Crusher Mounting - Perusahaan Uniflex Sdn Bhd

Perusahaan Uniflex Sdn Bhd - Cone & Jaw Crusher Mounting Supplier, Suppliers, Supply, Supplies Other Products and Services , We supply modumesh screening

Learn Moremount a jaw crusher

GreyHawk/ C3054 Portable Jaw Plant. The C3054 is an efficient primary jaw crusher for quarries, gravel pits, mines and recycling. Mounting of the crusher is made without a bolted connection

Learn MoreJaw Crusher | manufactor | thyssenkrupp Mining Technologies

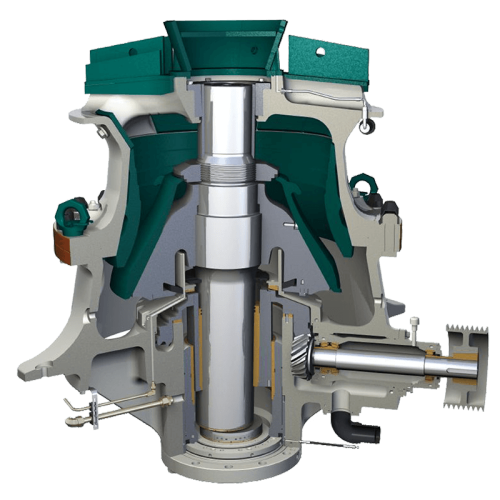

Double-toggle jaw crushers are the ideal machines for the hardest and most tenacious materials. They are equipped with a double-toggle system, which is controlled by a pitman that moves up and down under the influence of an eccentric shaft, causing the toggle plates to alternately flex and stretch. As a result, the swing jaw oscillates.

Learn Morejaw crusher installation dimensions

jaw crusher installation dimensions Jaw crushers are widely used in mining smelting building materials roads railways water conservancy and chemical

Learn MoreJaw crusher installation points and precautions

Since the jaw crusher is vibrating during operation, the machine should be installed on the concrete foundation. In order to reduce vibration,

Learn Morecrusher mantel | jaw crusher mounting

Aug 28, · Jaw crusher crushes on half-cycle and favors arrested crushing. The fixed jaw crusher foundation needs to be rugged to overcome the working stress. For gyratory crusher, the outer circle represents the stationary bowl covered by the concave and the inner circle represents the main shaft covered by the mantle.

Learn MoreJaw Crushers - Parker Plant

Options for mounting within static and mobile plant configurations. Rocksledger Jaw Crushers. Rocksizer. For primary stage medium to high capacity hard rock

Learn MoreJAW CRUSHER SERIES - Mining and Rock

The jaw crusher line is designed for the motor sizes listed in RPG and technical specifications. This means that for harder materials, the crusher will have to be operated at larger settings to avoid overload of drive and/or motor. Using oversized motors will lead to radically shorter crusher life and various mechanical problems.

Learn More