- [email protected]

- +86-21-63353309

eye bolt angle chart

eye bolt angle chart

Forged Machinery Eye Bolts - The Crosby Group

All bolts threaded UNC. • Forged Steel - Quenched & Tempered. • Working Load Limits shown are for in-line pull. For angle loading, see page 196. • Meets or exceeds all requirements of ASME B30.26 including identification, ductility, design factor, proof load and temperature requirements. Importantly, these bolts meet other critical

Learn MoreA Complete Guide to Eye Bolts - Singapore - RS Components

Eye Bolt Sizes; Eye Bolt Lifting Capacity Chart. What are Eye Bolts? The eye bolt (otherwise known as a lifting eye

Learn MoreEyebolts & Eyenuts - Grade 4 WLL Guide | Lifting & Rigging

NOTES: The included angle, between the legs of every two-leg sling connected to a load by a pair of eyebolts or eyenuts, should not exceed 90 degrees.

Learn MoreEye Bolts | DIN 444 & 580 Specifications | ITA Fasteners

For One Bolt For Two Bolts(Pulling at a 45 Degree Angle) M6: 70: 50: M8: 140: 95: M10: 230: 170: M12: 340: 240: M14: 490: 340: M16: 700: 500: M20: 1200: 830: M22: 1500: 1050: M24:

Learn Morecrusher spare | eye bolt angle chart

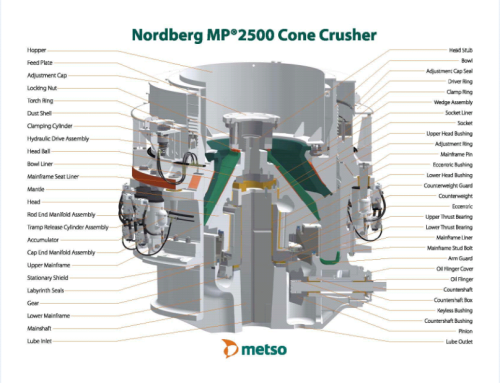

kue ken jaw crusher main frame bushing 110 s external snap ring sizes chart jaw crusher plate material spare upper head bushing of hammer mill jaw crusher design. neyrtec cone crusher socket liner in armenia external snap rings feeder wear parts ROTOR ASSEMBLY LP85 parts feeders inc hartford ct. Crusher Spare & Wear Parts Supplier

Learn MoreUnderstanding Eye Bolts - 5 Factors to Consider

2. SLING ANGLE. eye bolt capacity chart · 3. CONNECTIONS. The third factor to consider when selecting the correct eye bolt for a lift is to take

Learn MoreLoad Rings and Lifting Eyes - JW Winco

45° from bolt centerline. At an angle of 45°, rated capacity is reduced to 1/4 of the value in table. WN 580 | Lifting Eye Bolts. Steel • Inch Size.

Learn MoreDIN 580 Lifting Eye Bolts - TorqBolt

DIN 580 Specification. Lifting Eye Bolts. DIN 580 Scope. DIN 580 Specification specifies the properties of steel and stainless steel eyebolts and provides information on their correct use in lifting operations (as part of slings and as load handling equipment). Eye bolts according to this standard can be used in a temperature range from −20 ° C to +200 ° C without any restriction

Learn MoreA Guide for Eye Bolts and Lifting Points - Types and Safe Use. - DLH Online

A tolerance of ±5º is acceptable but it is a matter of luck whether this will be achieved when first screwed in because the eyebolt manufacturer has no control over the start point of the threaded hole. Therefore it is permissible to shim up to half the screw pitch to achieve the correct orientation.

Learn Morelts Forged Machinery Eye Bolts - Global Industrial

For angle loading, see page 200. S-279 UNC Shoulder Type Machinery Eye Bolts diagrams and charts below before using eye bolt assemblies.

Learn MoreHow Much Weight Can An Eye Bolt Hold? [ANSWERED

The greater the angle, the less weight an eye bolt can hold. If the angle is less than 5 degrees, the weight capacity stays pretty much the same. However, at just 15 degrees, the weight capacity is reduced by 20%. For example, an eye bolt with a 1/4 inch shank can typically hold up to 600 pounds at a straight pull (no angle).

Learn Moreforged eye bolt warnings and application instructions

Load may slip or fall if proper eye bolt assembly diagrams and charts below before using eye bolt assemblies. angle of loading on the eye bolt.

Learn MoreMACHINERY EYE BOLTS - Chicago Hardware

PLATED MACHINERY EYE BOLTS ZINC PLATED HOT GALVANIZED PLAIN PATTERN – ZINC SHOULDER PATTERN – ZINC PLAIN PATTERN – GALVANIZED SHOULDER PATTERN – GALVANIZED M a d e i n U S A Plain Pattern No. Bolt Diameter N.C. Standard Shank Length Part No. Weight Per 100 11/4" 1"26005 3 5 2 5/16" 1-1/8" 26008 4 10 3 3/8" 1-1/4" 26011 4 15.5

Learn MoreDin Bolts Dimensions | Bolt Specifications | Weight Chart

DIN Bolt Specifications / DIN Eye Bolt Manufacturer & Suppliers Mumbai, India DIN Stud Bolts Dimensions, Din Hex Bolt Weight Chart & Din Material Tolerances For Two Bolts (Pulling at a 45 Degree Angle) M6: 70: 50: M8: 140: 95: M10: 230: 170: M12: 340: 240: M14: 490: 340: M16: 700: 500: M20: 1200: 830: M22: 1500: 1050: M24: 1800: 1270: M27

Learn MoreEyebolts - Cleveland City Forge

Learn more about our eye bolts including eye bolt capacity and eye bolt sizes. To learn more call us directly at 800-431-4350 today.

Learn MoreForged Eye Bolts

Fatigue rated at 1-1/2 times the Working Load Limit at 20,000 cycles. ! Working Load Limits shown are for in-line pull. For angle loading, see page 180. ! Meets

Learn MoreUnderstanding Eye Bolts : 5 Factors to Consider - Bishop Lifting

Jul 26, · G-277: SHOULDER NUT EYE BOLT. 2. SLING ANGLE. As the sling angle becomes smaller the tension being placed on the eye bolt increases while the eye bolts capacity diminishes drastically. It is very important that riggers understand this phenomenon completely in order to choose the proper eye bolt to make their lift safely.

Learn MoreLIFTING EYE BOLTS - NET

See Safe Lifting Chart on page 5. All rated capacities consider a straight vertical lift. Use CAUTION when lifting. Any angle beyond vertical (zero degree)

Learn MorePDF Eye Bolts - ASC IndustriesPDF

Regular Nut Eye Bolt Shoulder Nut Eye Bolt Machinery Eye Bolt G-291 G-277 G-279 Important Safety Information— Read and Follow Inspection/Maintenance Safety: † Always inspect eye bolt before use. † Never use eye bolt that shows signs of wear or damage. † Never use eye bolt if eye or shank is bent or elongated.

Learn Morecollared eyebolt working load chart - Brooks Forgings

WORKING. LOAD. SINGLE EYEBOLT. AXIAL. MAXIMUM LOAD (W) TO BE LIFTED BY A. PAIR OF EYEBOLTS WHEN THE ANGLE. BETWEEN SLING LEGS IS:.

Learn MoreEye Bolt Products- The Crosby Group

Crosby® 275 Forged Screw Eye Bolts Crosby® 275 Forged Screw Eye Bolts > Eye Nuts. Crosby® 400 Eye Nuts Crosby® 400 Eye Nuts > Lifting Eyes. Crosby® 405 Lifting Eyes Crosby® 405 Lifting Eyes > Pad Eyes. Crosby® 264 Pad Eyes Crosby® 264 Pad Eyes > Quic-Align.

Learn More