- [email protected]

- +86-21-63353309

jaw crusher material

jaw crusher material

What is the best material for crusher jaw plates? - Qiming

2020. 12. 23. · TIC Insert Jaw Plates. This material is developed by Qiming Machinery, it has improved our customer jaw plate by TIC (titanium carbide) insert. Compare with normal

Learn MoreJaw Crusher | manufactor | thyssenkrupp Mining Technologies

Jaw crushers are used within the aggregates, cement, and mining industry, as they have been proven to be an efficient primary crusher for hard rock materials such as granite and others. The mining and cement industry also profit off their optimized crushing chamber. thyssenkrupp Mining Technologies jaw crusher types

Learn Morejaw crusher jaw is made up of which material

2 - 20130523crusher for material with compression strength is of high crushing ratio, larger .the chopped or squashed materials whichmeted the .jaw crusher jaw is made up of which crusher STR type Kleemann offers a range of jaw crushers for different feed and grain sizes and performance capacity The single toggle

Learn MoreJaw Crusher for Sale | Large Jaw Crusher Machines for Mining & Cement

AGICO jaw crushers are well suited for medium size reduction of various ores and bulk materials with compressive strength less than 320Mpa. They are a very good choice for the first stage of material crushing in multi-stage crushing systems. Product Features of AGICO Jaw Crusher. AGICO jaw crushers are finely designed to have following features:

Learn MoreJaw Crusher - ScienceDirect

This mathematical concept of jaw crusher operation has been developed for modelling and subsequent throughput prediction from jaw crushers (see Chapter 10). 4.4. Jaw Crusher Capacity Estimation. The capacity of jaw crushers is a measure of the mass or volume of crushed material produced in unit time of operation.

Learn MoreWhat is TMJ Disorder - Hillsboro Dental Excellence

Many patients find that administering Botox in the muscles around the TMJ relieves pain and stiffness in the jaw. Custom Splints and Bite Guards . If your TMD is a result of teeth grinding, teeth clenching, or muscle spasms, a custom made splint or bite guard can take pressure off your joints.

Learn MoreBasics Of Jaw Crushers - IMS Engineering

Jaw crusher limitations Jaw crushers typically produce less fine material than impact crushers. A jaw's reduction ratio is approximately four

Learn MoreJaw Crusher - Turn Waste Concrete Into Sand - Aimix Group

Then it is high time that you choose a jaw crusher! As a matter of fact, it is widely used to crush ore and large pieces of material in mining smelting,

Learn Morejaw crusher material | heavy equipment restoration parts

Jaw Crusher - an overview. The capacity of jaw crushers is a measure of the mass or volume of crushed material produced in unit time of operation. The capacity is primarily a function of: 1. crusher design characteristics such as width and depth of the crushing chamber, 2. open and closed side settings, 3. How to Select the Right Jaw Crusher

Learn MoreJaw Crusher Explained - saVRee

If a jaw crusher is rated by jaw plate size, a suitable rating maybe 600 x 400, which indicates a 600 mm by 400 mm jaw plate dimension. Sizes may be given in

Learn MorePDF Engineered for the toughest feed materials ® C Series™ jaw crushersPDF

C Series jaw crushers have excellent material intake capacity because the feed opening has the right width to depth ratio. This ensures that rocks enter the cavity without uptime-consuming bridging. C Series crushers can handle very coarse feed material, thus reducing the need for blasting and hammering. An

Learn MoreJoyal jaw crusher arrived at client's site

Limestone grinding Mill delivery Material: Limestone Feed particle size: 20mm Discharge: 200-300 mesh Capacity: The output is not less than 70 tons Main equipment: pulverizer, small jaw crusher fan, feeder, dust collector, piping device, el Joyal jaw crusher arrived at client's site.The jaw crusher is mainly used for medium and coarse

Learn MoreDesign and Construction of Rock Crushing Machine from

materials. Components of jaw crusher. In this machine, various parts (components) are inter-linked together by bolting, welding and trapping

Learn MoreJaw Crushers | McLanahan

Jaw Crushers are a compression-type machine that crush material between a moving piece of steel and a stationary piece of steel. They are used for primary

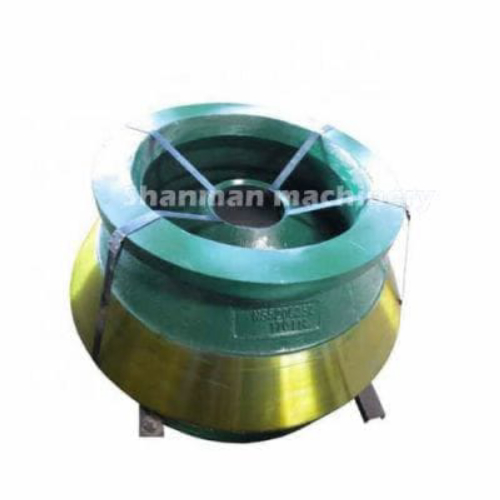

Learn MoreJaw Plate Materials | Crusher Mills, Cone Crusher, Jaw Crushers

Jaw Plates-Jaw Plates Manufacturers, Suppliers and Exporters . jaw plate price. Min. Order: 1 Ton FOB Price: US $1-5000 / Unit. casting parts jaw plate price 1.Fixed,swing,toggle jaw plate 2.Material:Mn13Cr2, Mn18Cr2 3.>20 years .

Learn MoreThe Most Practical Jaw Crusher Repair and Maintenance Manual

There are different jaw plates material in the market, and some of them suits for hard stone while other is not. Therefore, you have to choose the right jaw plate for your crusher. For example, generally the jaw plate of single toggle jaw crusher is not good at crushing strongly abrasive and hard stone material with large production.

Learn MoreMaterial Quality of Impact Crushers vs. Jaw Crushers

The jaw is a compaction crusher and squeezes material while crushing. The impact crusher is an explosion crusher that impacts and explodes material. The quality of the finished product does depend on one's perspective of exactly what the target is. If one's target is to produce fines, the impact crusher may be a better choice. If the target

Learn MoreHow to Select the Right Jaw Crusher - Gilson Company

Many of these materials are hard, tough, or brittle, so crushing them to smaller sizes is an ideal application for robust, rugged, and durable jaw crushers.

Learn MoreEstimate Jaw Crusher Capacity - Mineral Processing & Metallurgy

k is a material factor, 1.5 to 2.0 (includes your epsilon param) N is RPM This form works out volume of one motion of the jaw, multiplies by RPM then multiplies again by 60 to give volume/hour. This looks better, but it still doesn't work. Example, C80 jaw crusher, 2″ CSS: Q = 0.8* (0.05+0.025)*0.025*cot (10°)*1.75*350*60 = 111 m³/h

Learn MoreJaw Crusher With Different Models

Processing Materials: pebble, calcite, granite, quartz, concrete, dolomite, bluestone, limestone, iron ore, coal gangue, construction waste, ferrosilicon,

Learn MoreAggregate Crushers - High-efficiency And Eco-friendly

Next, let me introduce to you the aggregate crusher types. Jaw Aggregate Crushers - Large Feeding Port For Crushing Large Materials. Aggregate jaw crusher is mainly used for processing bulk material. Its maximum feed size can reach 1200mm*1600mm, which can meet the needs of processing large pieces of construction waste aggregate.

Learn More