- [email protected]

- +86-21-63353309

css jaw crusher

css jaw crusher

Engineered for the toughest feed materials ® C

adjust CSS and feed rate. IC10C can be connected to customer's plant wide automation by using standard communication protocols. Metrics fleet ® C Series™ jaw crushers are designed to handle the toughest feed materials in the primary crushing stage. They have proven their performance in at least 10,000 reference cases since

Learn Morevn/css cone crusher.md at main · /vn - GitHub

Our cone crushers have large feed size opening (to accept odd oversized material coming out of jaw crusher),and a large setting range to ensure

Learn MoreJaw Crushers | McLanahan

The Jaw Crusher was first introduced by Eli Whitney Blake in 1858 as a double-toggle Jaw Crusher. Introduced in 1906, McLanahan’s Universal Jaw Crusher was one of the first

Learn MoreC96™ jaw crusher - Outotec

C96™ jaw crusher is an all-round crushing machine well equipped to serve in stationary and mobile applications both on the ground and underground. Generally used as a primary crusher, ® C96™ can also be utilized in later stages of the size reduction process. Extremely reliable. Outstanding performance.

Learn MorePDF Measuring the Crusher OSS CSS Closed Side SettingPDF

How to check the opening of the jaw crusher Whenever a jaw crusher is off and at rest (stopped), it will remain in the open position at its open-side setting (OSS). However, the adjustment of your crusher is performed at its closed-side setting (CSS). OSS is measured while the crusher is stopped.

Learn MoreCrusher Close Side Settings - 911 Metallurgist

The closed side setting can be calculated by deducting the stroke from the OSS. CSS is the most important crusher parameter since it defines the

Learn MoreClosed Side Setting (CSS) Measurement Device

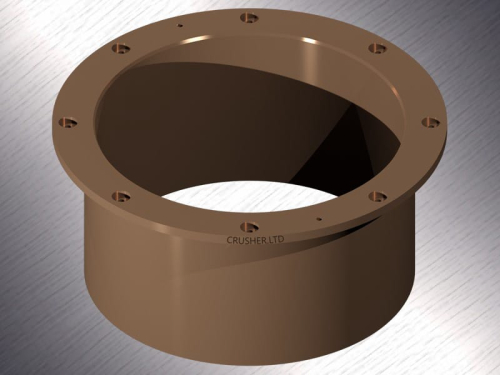

Crusher Operation What is the Closed Side Setting (CSS)?-Minimum gap setting of when the mantle bowl rotates within the crusher or moving plate is closest to the fixed plate in a jaw

Learn Morecss in jaw crusher

Mobile Jaw Crusher Closed Side Setting (CSS) range. CSS is the smallest discharge opening dimension on the jaw. OSS is the largest discharge opening dimension on the jaw. It is equal to the CSS plus the throw of the swing stock. The dimension on the discharge end of the jaw liners are measured from Peak to Root.

Learn MoreHow to measure css and oss jaw crusher - Bensheim Mining Machinery

5-1 Gape CSS OSS Gape Figure 51 Schematic diagram of a crusher showingg the open- and closed-side settings 51 Jaw and Gyratory Crushers Jaw and gyratory crushers Crusher A gyratory crusher is similar in basic concept to a jaw crusher consisting of a concave surface and a conical head both surfaces are typically lined with manganese

Learn Morecss on jaw crushers

Optimalisasi Closed Side Setting (CSS) Jaw Crusher. Based on the initial CSS jaw crusher settings that have been applied, it is 80 mm which results in a split production of 172.51 tons / day with a return percentage of 9.04% and a work efficiency of 62.88%. For the second CSS reset, it is known that it is 70 mm, resulting in a split production

Learn MoreCss Jaw Crusher Setting Mm For Mm Product

Jaw Crusher Series. The jaw shim plate is installed on the fixed side, except on cj211 and cj412 where the two plates are installed on both sides.This is optional equipment.Jaw shim plate is installed instead of the wear plate.2 jaw crusher series css mm cj211 60 110-160 70 120-180 80 135-205 90 150-230 100 160-250 125 195-310 150 230-370.

Learn Morejaw crushers for all your needs - Lutze Process

All our jaw crushers are of the single The jaw crusher is a single toggle jaw crusher, characterized smaller than the crusher's CSS.

Learn MoreHow to Calculate and Solve for Capacity of Jaw Crusher | Mineral

Find the gape size when the capacity of jaw crushers is 5, the width of crusher is 3 and the closed single setting of jaw crusher is 6. This implies that; C JC = Capacity of Jaw Crushers = 5. W = Width of Crusher = 3. CSS = Closed Single Setting of Jaw Crushers = 6. G = CJC x CSS / W. G = 5 x 6 / 3. G = 30 / 3.

Learn MoreCrushing & Screening Tip #4 - CSS (Closed Side Setting

You need to allow for the stroke of the crusher - a CSS of 75mm on a jaw crusher will result in a finished product of 115mm-150mm with a 40mm

Learn MorePDF Engineered for the toughest feed materials ® C Series™ jaw crushersPDF

C Series jaw crushers have a strong pinned and bolted, non-welded frame construction and the highest power ratings in each size class, which brings benefits to stationary, underground and mobile crushing applications. They are designed to the highest safety standards to make the use and maintenance as easy as possible.

Learn MoreCJ412 Jaw crusher - rockprocessing

Advantages ; Capacity (by hour), 165 - 790 mtph ; Motor power, 132 kW (200 hp) ; Closed side setting (CSS) range, 75 - 275 mm (2.9 - 10.8 in.) ; Jaw plates, CC, ST,

Learn MorePower draw of the crusher when varying the speed and CSS

For instance, jaw and gyratory type crushers are mainly used to break down huge rock blocks in crushing -screening plants and, therefore, they are declared

Learn MoreC Series™ jaw crushers - Outotec

C Series™ jaw crushers have proven to be reliable and productive in thousands of mining, quarrying, recycling and industrial applications with up to 11,000 jaw crusher installations since 1975. Developed to crush the hardest ores and rocks, jaw crushers also perform outstandingly with less demanding materials.

Learn MoreCone crusher basics in 4 minutes — SRP

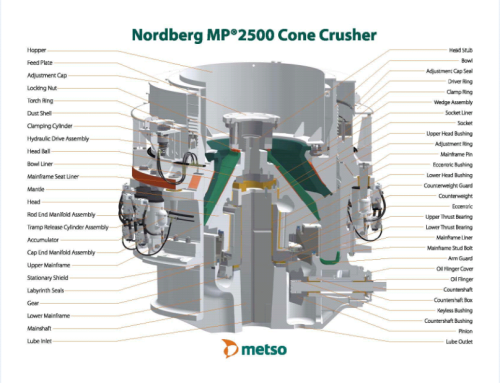

As the smallest distance between the concave and the mantle, the CSS is the final crushing zone, and is vital for determining the product size, as well as

Learn MoreTrio® CT4254 Series Primary Jaw Crusher - The Weir Group

Trio® CT series jaw crushers are available in an extensive range of sizes suitable for mobile Average production rate for range of CSS.

Learn MoreAMIT 135: Lesson 5 Crushing - Mining Mill Operator Training

Measurement of the crusher's closed side setting (CSS) varies depending on the jaw profile that is being used and has an impact on the crusher's capacity

Learn More