- [email protected]

- +86-21-63353309

parker cartridge valves pdf

parker cartridge valves pdf

PDF Catalog HY15-3502/US Contents Bodies and Cavities - Fluid Power SolutionsPDF

Parker Hannifin Corporation Hydraulic Cartridge Systems Aluminum and Steel Bodies Light weight aluminum bodies are available for low pressure applications. Durable steel bodies are available for higher pressures. Slotted Mounting Holes Allows several bodies to be stacked together and held by one set of bolts. Yellow Zinc Coating

Learn MorePDF 20SLC2 B - hydradynellc.comPDF

Specifications Technical Information Rated Flow303 LPM (80 GPM) Maximum Inlet240 Bar (3500 PSI) Pressure Leakage @Port 1 to 2 150 SSU (32 cst)82 cc/min. (5 in3/min.) @ 240 Bar (3500 PSI) Cartridge MaterialAll parts steel. All operating parts hardened steel. Operating Temp.-45°C to +93.3°C (Polyurethane) Range/Seals(-50°F to +200°F)

Learn MorePDF Direct Acting Relief Valve Technical Information Series RD102PDF

Parker Hannifin Corporation Hydraulic Cartridge Systems Specifications Technical Information Rated Flow38 LPM (10 GPM) Maximum Inlet250 Bar (3600 PSI) Pressure Maximum210 Bar (3000 PSI) Pressure Setting Maximum Tank210 Bar (3000 PSI) Pressure Reseat Pressure85% of crack pressure Leakage at5 drops/min. (.33 cc/min.)

Learn MorePDF Catalog HY15-3501/US Contents Proportional ValvesPDF

Parker proportional valves. The override is generally a push type that is flush with the end of the tube. Consult the individual catalog pages for more details. TECHNICAL TERMS To help in applying our proportional valve line of product, we have listed some technical terms below, as well as some helpful hints in applying our valves.

Learn MoreContents Slip-In Cartridge Valves - Hidroser

Parker Hannifin Corporation. Hydraulics Group. Catalogue HY11-3500/UK. 8. 8-1 content08.INDD CM 28.08.13. Contents. Chapter 8: Slip-In Cartridge Valves.

Learn More2-Way Slip-In Cartridge Valve - Series CE, CP | Parker NA

2-way slip-in cartridge valves series CE and CP are hydraulically controlled seat valves which are universally applicable. The complete modular system covers all sizes.

Learn MoreHydraulic Cartridge Systems

2014. 2. 19. · Parker is a recognized leader in integrated circuit design focusing on flexibility, innovation and support. Application engineering and manufacturing support facilities are located throughout North America, Europe, Scandinavia and in other areas around the world. The Parker Hydraulic Cartridge Systems Applications Engineering team is thoroughly

Learn More2-Way Slip-In Cartridge Valves Characteristics Series CE, CP, C

Slip-in cartridge, cover, and pilot system are valve elements that permit single and combined functions. Series CE offers poppet and sleeve combinations for.

Learn MoreParker Valve Industrial DIN Slip-In Cartridge Valves - Scribd

Parker Valve Industrial DIN Slip-in Cartridge Valves.pdf - Free download as PDF Parker Hannin Corporation Hydraulic Valve Division Elyria, Ohio, USA.

Learn MoreParker 7321B/ 7322B Series Water Valves

Parker 7321B/7322B are diaphragm pilot operated solenoid valves and require a minimum differential pressure to operate. This serie is available in both Normally

Learn MoreParker Valve Cartridge Load and Motor Control Valves

2012. 12. 3. · LM1 Load and Motor Control Valves Catalog HY15-3502/US Technical Tips Parker Hannifin Corporation Hydraulic Cartridge Systems Check Valves Shuttle Valves Load/Motor Controls Flow Controls Pressure Controls Logic Elements Directional Controls Manual Valves

Learn MoreSolenoid Valves Contents - TAIYO

Parker Hannifin Corporation. Hydraulic Cartridge Systems. Check. Valves. Shuttle. Valves. Load/Motor Manual Overrides: Many of our solenoid valves are.

Learn MorePDF Parker Valve Industrial DIN Slip-In Cartridge ValvesPDF

Series CE and C 2-way slip-in cartridge valves are hydraulically controlled seat valves that are designed for compact block installation. Slip-in cartridge, cover, and pilot system are valve elements that permit single and combined functions. Features •Installation cavity and mounting pattern according to ISO 7368. •One sleeve only for all poppets.

Learn MoreA04B2PZN - Direct Acting Relief Valves | Parker NA

Parker’s direct acting relief valves are available in several cavity sizes and are designed for continuous duty applications with pressures up to 420 bar Screw in cartridge valve; Cavity Size: C10-2; Function: HY15-3503R1.pdf: Pressure Control Technical Tips:

Learn MorePDF Hydraulic Cartridge Systems - Industrial Automation SupplierPDF

Cartridge Style Check Valve. For additional information see Technical Tips on pages CV1-CV4. Features •Spherical poppet for low leakage •"D"-Ring eliminates back-up rings •Dual sense paths for reduced P •All external parts zinc plated Catalog HY15-3502/USSuper Coil Series 5/8 I.D.

Learn MorePDF Parker Valve Cartridge Directional Control ValvesPDF

Diverter Valve, Normally Open, Pilot to Close Vent and Pressure Compensating Flow Control Element. Features •Two switching and one compensating spring available •Very accurate flow regulation when used with separate orifice •Sealed pilot option available •Industry common cavity •Hardened working parts for maximum durability

Learn MoreParker-Hydraulic-Cartridge-Systems-HY15-3502.pdf

The individual product catalog pages detail fully the product specifications and operating parameters of each valve. Additionally, dimensional information, as

Learn MoreParker Hannifin - Relief Valves Technical Information Series

2008. 3. 17. · Parker Hannifin Corporation Hydraulic Valve Division Elyria, Ohio 44035 USA Relief Valves Series RAH101 Performance Curve Flow vs. Inlet Pressure (Pressure rise through

Learn MoreCatalog HY14-2500/US - Regional Hose

Industrial Hydraulic Valves. Catalog HY14-2500/US intro-index.indd dd. III. Parker Hannifin Corporation. Hydraulic Valve Division. Elyria, Ohio, USA.

Learn MoreCP084P - Wainbee

Parker Hannifin Corporation. Hydraulic Cartridge Systems. Check. Valves. Shuttle. Valves. Load/Motor. Controls. Flow. Controls. Pressure. Controls.

Learn MoreCartridge Valves | ParkerCA - Parker Hannifin

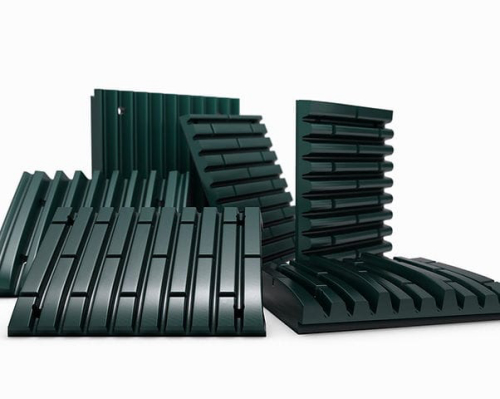

Our cartridge valves offer numerous features and benefits including a space-saving approach, less manifold machining for a lower manifold cost, and no manifold orifices to machine or press in. Additionally, cartridge valves are 100% tested and there are no loose parts; the sleeve, plunger, spring and orifice are pressed together as one unit.

Learn More