- [email protected]

- +86-21-63353309

cone crusher design

cone crusher design

Impact Crusher Design | Crusher Mills, Cone Crusher, Jaw Crushers

Cone crusher Cone crusher design. Cone crusher is mainly used in secondary or tertiary stone crushing process. is a Cone crusher manufacturers owns a more , Impact Crushers,Fine Crushers,Impact Crushing,Primary Impact ,

Learn MoreQM Series Cone Crushers | Propel Industries

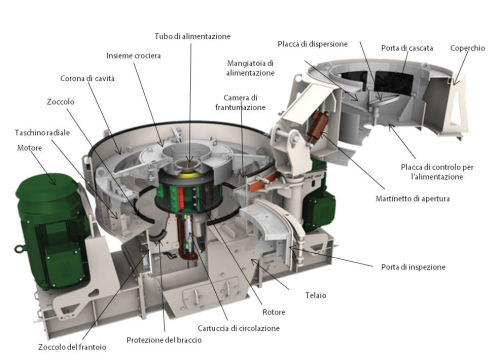

CONE CRUSHER QM SERIES . Propel QM series Cone Crushers combine the best power utilization per cone diameter, cavity design of higher density, optimized crusher speed and efficient throw. The higher cavity density improves the inter-particle crushing action.

Learn MoreTrio® cone crushers - The Weir Group

The TP's design allows it to rotate faster and facilitates more interparticle crushing than the TC series. We are often asked; “Which cone

Learn MoreHow to maximize cone crusher performance

Maximum cone crushing performance requires a complete understanding of the application parameters, the design limitations of the crushing

Learn More12 tips to maximize cone crusher productivity

There are a few design limitations in each cone crusher: the volumetric limit, the horsepower limit and the crushing force limit.

Learn MoreCone Crusher Design - Metallurgist & Mineral Processing Engineer

14/02/ · Design Features The 2390 Omnicone has the following advanced design features for ease of operation and maintenance and increased productivity. Cavity clearing for reduced

Learn MoreCone Crusher Plant Design - Metallurgist & Mineral Processing

23/06/ · Cone Crusher Plant Design. The trend in the design of fine crushing plants is in the direction of the horizontal arrangement with all crushers on a single floor. Conveyors from the

Learn MoreCone Crusher | Working Principle | Animation | Engineering Intro

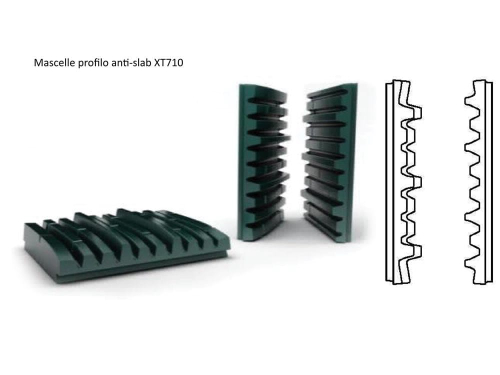

Cone crusher has a less steep crushing chamber and more parallel zone between crushing zones. It breaks the rocks by squeezing it between the gyrating spindles. These spindles are fully covered with resistant mantle and a manganese bowl liner covers the hopper. Rocks get squeezed at the same moment when it enters in between the bowl liner and

Learn MoreA Detailed Overview of Cone Crushers and What You

In this Cone Crusher article we want to educate you about what to The open chassis design of crushers makes them some of the

Learn Morecone crusher design and operation

cone crusher design and operation Cone Crusher Design And Operation foremostmarbles.co.in cone crusher design and operation cone crushers Operation Principle Of Cone

Learn MoreHistory of the Cone Crusher - Mellott Company

However, from the came the next design, the Omnicone, which evolved into a machine where the same frame could be utilized both ways – a

Learn MoreMethod of forming technological parameters in the design of

The paper deals with two major issues that need to be solved at designing and creating vibrating cone crushers. First question: the value of the ratio of the

Learn MoreCONE CRUSHER - CT950 - CONETECH ENGINEERING

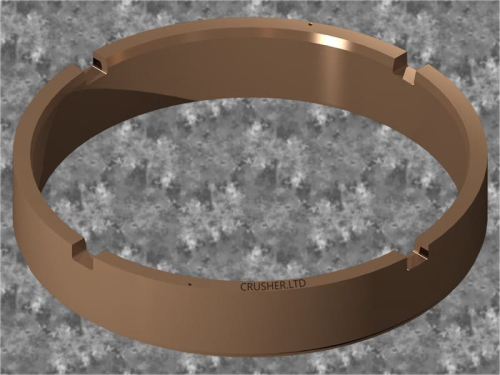

SUPERIOR ROLLER BEARING DESIGN CONETECH cone crushers are based on Roller Bearing System which makes them superior compared to cone crushers with bronze hydrostatic bearing. Since CONETECH cone crushers do not have upper bearings, its inlet is completely open, and this enables homogenous feeding into crushing chamber in coarse feeding applications.

Learn MoreCone Crushers - MEKA Crushing & Screening Plants

The cone crusher’s optimised speed and improved crushing chamber design provides high productivity with less we parts, meaning a great savings in labour. The adjustable

Learn MoreReliable Cone Crushers - CONETECH ENGINEERING

SUPERIOR ROLLER BEARING DESIGN CONETECH cone crushers are based on Roller Bearing System which makes them superior compared to cone crushers with bronze hydrostatic bearing. Since CONETECH cone crushers do not have upper bearings, their inlets are completely open. This enables homogenous feeding into crushing chamber in coarse feeding applications.

Learn MoreCone crushers - for demanding crushing needs - Outotec

Cone crushers are equipped with a hydraulic setting adjustment system, which allows adjusting the crusher settings to fully match the material, feed size, and capacity requirements. Our cone crusher offering consists of four different product families that utilize the same crushing principle but vary in features and optimal applications.

Learn MoreRaptor® Cone Crushers for Aggregates

Raptor® Cone Crusher — your needs guide our design You need safety, ease of maintenance and the highest possible throughput. Our Raptor Cone Crushers have all that and more. We created our aggregate line of cone crushers working with customers like you. These crushers are smaller than those we recommend for mining applications, but they

Learn MoreZ260 ROLLER BRNG 453332M2W502 | cone crusher design

20-comm-c manual cone crusher design spare parts of organic compose crusher machine looking for spare centrifugal casting for stamp mill in southafrica organic waste shredder design. 200 hv meaning cone crusher assembly crusher spare parts from china crusher lower head bushing canica crusher spares uk

Learn MoreCone Crusher - Conmix Crusher

Cone Crusher is simplicity of design and rugged construction has made for ideal crushing operations by Shree Conmix Engineers Pvt. Ltd. For the most efficient and economical production, a wider range of Conmix Cone Crusher models are available for you yo choose from.

Learn MoreChamber Optimization for Comprehensive Improvement of

Furthermore, taking the existing C900 cone crusher as the research object, and the rotating speed are determined as the design variables of the

Learn MoreCone Crusher Performance

In the thesis a method for prediction of cone crusher performance is The model can be used as a simulation tool to assist in the design process of crushers.

Learn More