- [email protected]

- +86-21-63353309

stone crushing process pdf

stone crushing process pdf

PDF 11.19.2 Crushed Stone Processing - epa.govPDF

11.19.2 Crushed Stone Processing 11.19.2.1 Process Description1-2 Major rock types processed by the rock and crushed stone industry include limestone, granite, dolomite, traprock, sandstone, quartz, and quartzite. Minor types include calcareous marl, marble, shell, and slate.

Learn MorePDF) Experimental study of crushing process of the crushed stone

PDF | Currently, crushers operating in a central impact manner have become widely used, which has several advantages over roller, cone, and cheek | Find, read and cite all the research you need

Learn MorePre-Feasibility Study - Ministry of Commerce

2021. 2. 27. · 5.1 Stone Crushing - Production Process The main machinery involved in the stone crushing industry is Hammer Crusher, Vibrators, Rotor, Conveyers and Support Structure. The

Learn MoreThe Complete Guide to Crushed Stone and Gravel

2019. 11. 11. · Crushed stone: The term “crushed stone” usually refers to stone that has a mixture of stone dust in it. This type of stone is best used for a base when heavy compaction is needed. As a result, it is typically used for the base of concrete and paving projects, foundations of structures, and driveway bases.

Learn MoreHighway Stone Crushing Plant And Process Pdf

Production Stone Crushing Mtbvorselaar. Coal crushing plant production flowsheet.Process flowsheet of coal mining plant, highway stone crushing plant and process pdf; coal preparation process flow; posts related to process flowsheet of a mining.Typical process flow sheet for steam coal production sieve bends/ clean.Buy stone and sand crushing production line in -

Learn MorePDF AP-42 Section 11.19.2 Crushed Stone Processing and Pulverized ... - US EPAPDF

11.19.2.1 Process Description 24, 25 Crushed Stone Processing Major rock types processed by the crushed stone industry include limestone, granite, dolomite, traprock, sandstone, quartz, and quartzite. Some stone crushing plants produce manufactured sand. This is a small-sized rock product with a maximum size of 0.50 centimeters (3/16 th

Learn MoreAP-42 Section 11.19.2 Crushed Stone Processing and Pulverized

2015. 9. 10. · Crushed Stone Processing . Emissions of PM, PM-10, and PM-2.5 occur from a number of operations in stone quarrying and processing. A substantial portion of these

Learn MorePDF Stone Crushing Process Flows - sinojawcrusher.comPDF

Stone Crushing Process includes vibrating feeder, jaw crusher, cone crusher, impact crusher, vibrating screen and belt conveyor etc. We design this stone crushing production line with the capacity from 50t/h to 500t/h, and supplies a whole set of stone crushing production line. Also, if you have special needs, we can design a line especially

Learn MoreCrushing Plant Design and Layout Considerations - Metallurgist & Mineral Processing

2016. 2. 24. · • Electronic control of crusher discharge opening and feed rate. With adjustment of a crusher’s discharge opening, as the production continues through an on-line coarse size analysis of the crushed product (digital image analyses). Dance, A. 2001) • More attention is being paid to the impact on crushing circuit design caused by variations

Learn MoreSTONE CRUSHER - PHD

2018. 8. 21. · involved in the stone crushing industry is Hammer Crusher, Screen, Conveyors etc. The process involved is to feed the stone in to the Hammer Crushers to make it further smaller

Learn MorePDF Design and Construction of Rock Crushing Machine from Locally Sourced ...PDF

Design and Construction of Rock Crushing Machine from Locally Sourced Materials for Indigenous Use Introduction Crushing is one of the preliminary stages in mineral processing from the ore. The process is required to reduce rocks and lumps to smaller pieces. Rollers or jaw crushers are employed in this situation.

Learn MorePDF Pre-Feasibility Study - Ministry of CommercePDF

5.1 Stone Crushing - Production Process The main machinery involved in the stone crushing industry is Hammer Crusher, Vibrators, Rotor, Conveyers and Support Structure. The process involved is to feed the stone in to the Hammer Crushers to make it further smaller in size as required by the customer. In the hammer crusher, the stone is crushed.

Learn MorePDF Crushing Plant - crusherinc.comPDF

Process of 180-200 TPH Jaw & Cone Crushing Plant >> E-Mail:[email protected] >> Http://www.crusherinc.com Big materials are fed to the jaw crusher evenly and gradually by vibrating feeder through a hopper for primary crushing. After first crushing, the material will transferred to cone crusher by belt conveyor for secondary crush;

Learn MoreCrushing Principles of Mechanical Crushing - Metallurgist & Mineral Processing

2016. 1. 12. · Optimization of a Final Crushing Stage This method applies to other crushers where a control variable is available The crushers are the last size reduction stage in the value chain. Over crushing is common. The connection between crusher setting and yield is often unknown The rock cannot be repaired. We need to control the crusher

Learn MorePDF Design of impact stone crusher machine - CitefactorPDF

design impact stone crusher. Impact stone crusher involves the use of impact rather than pressure to crush materials. The material is held within a cage, with openings of the desired size at the bottom, end or at sides to allow crushed material to escape through them. Impact stone crusher is used with soft materials, medium to hard stones and

Learn Morerock crusher machinery process principle pdf

OPERATION AND MAINTENANCE OF CRUSHER HOUSE FOR. In CHP crusher work on principle of combination of impact and attrition crushing.In this type of crushing first coal is break due t

Learn MoreConstruction Working and Maintenance of Crushers for Crushing

2018. 12. 26. · 1 Construction, Working and Maintenance of Crushers for Crushing Bulk Materials www.practicalmaintenance.net Construction, Working and Maintenance of Crushers for Crushing Bulk Materials By K. P. Shah Email: kpshah123[at]gmail.com (Please replace [at] with @) Committed to improve the Quality of Life For more articles on mechanical maintenance, visit

Learn MoreSTONE CRUSHERS STCH

MODEL STCH 200 STCH 225 STCH 250 Tractor (hp) 280-400 280-400 280-400 PTO (rpm) 1000 1000 1000 Working width (mm) 2080 2320 2560 Total width (mm) 2566 2806 3046 Weight (kg) 4850 5050 5250 Rotor diameter (mm) 695 695 695 Max shredding diameter (mm) 500 500 500 Max working depth (mm) 250 250 250 No. teeth type STC/3+STC/3/HD+STC/FP 50+4+4

Learn MorePDF 11.19.1 Sand And Gravel Processing - US EPAPDF

emission factors for the crushing, screening, and handling and transfer operations associated with stone crushing can be found in Section 11.19.2, "Crushed Stone Processing." In the absence of other data, the emission factors presented in Section 11.19.2 can be used to estimate emissions from corresponding sand and gravel processing sources.

Learn MoreComprehensive Industry Document Stone Crushers

2018. 11. 19. · Bridges, Canals etc. Stone Crushers also need electricity supply and large number of man power for its operation. It also needs access roads for the movement of mined stone

Learn MorePDF Crushing Plant Design and Layout ConsiderationsPDF

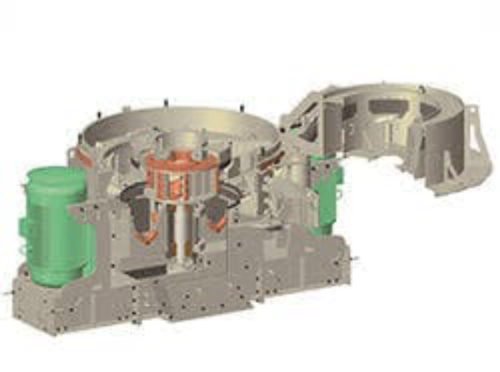

There are three main steps in designing a good crushing plant: process design, equipment selection, and layout. The first two are dictated by production requirements and design parameters, but the layout can reflect the input, preferences and operational experience of a number of parties.

Learn More