- [email protected]

- +86-21-63353309

blake jaw crusher

blake jaw crusher

disadvantages of black type jaw crusher

Advantages And Disadvantages Of Dodge Jaw Crusher. 7 27 Advantages and disadvantages of blake jaw crusher reasons to use jaw crushers advantages and

Learn MoreCharacteristics and Comparison of Four Types of Jaw

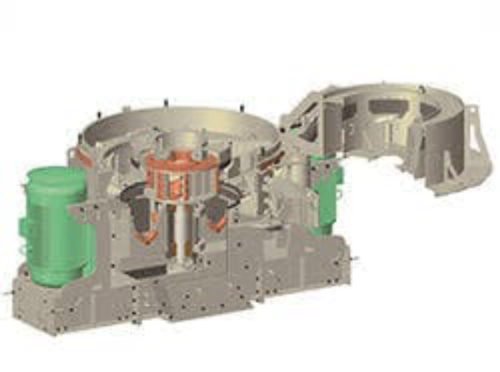

There are two jaws in a blake jaw crusher, one is stationary and vertical, the other is movable and swing.

Learn MoreJaw Crusher Capacities, Blake and Single-Toggle Or Overhead

Blake-type jaw crushers. The results of these tests were summarized in a simple first degree equation applicable to crushers using either straight or curved jaw plates. This equation first outlines the maximum capacity potential of a given crusher, then reduces this figure in accordance with installation circum-

Learn Moreparts of blake jaw crusher crusher worm wheel manufacture

There are two jaws of a Blake jaw crusher, one is the moving jaw and the other is fixed jaw Abstract— Keywords IJSER. Jaw crusher movement is guid-ed by pivoting one end of the swinging jaw. and an eccentric motion located at the opposite end [4]. 1.3 Different Types of Jaw Crusher . According to the amplitude of motion of the moving face

Learn MoreJaw Crusher - an overview | ScienceDirect Topics

A material is crushed in a Blake jaw crusher such that the average size of particle is reduced from 50 mm to 10 mm with the consumption of energy of 13.0 kW/(kg/s). What would be the

Learn MoreThe Blake Rock Crusher – Today in History: June 15

On June 15, 1858, Eli Whitney Blake of New Haven was granted US patent No. 20542 for a “machine for crushing stone.” The nephew of cotton-gin inventor Eli

Learn MoreJaw Crushers | McLanahan

The Jaw Crusher was first introduced by Eli Whitney Blake in 1858 as a double-toggle Jaw Crusher. Introduced in 1906, McLanahan’s Universal Jaw Crusher was one of the first modern era overhead eccentric Jaw Crushers. On the overhead eccentric style Jaw Crusher, the moving swing jaw is suspended on the eccentric shaft with heavy-duty double

Learn MoreBlake Jaw Crusher Specification-HN Mining Machinery

Blake jaw crusher is type of jaw crusher, wherein the swing jaw is pivoted at the top. On the basis of toggle, the market has been segmented into single and double. The double toggle jaw crusher segment held the largest market share of the global jaw crusher market in and is expected to witness the highest CAGR during the forecast period.

Learn MoreBlake Jaw Crusher--Discontinued - Mobil

Blake Jaw Crusher--Discontinued. Toggle. Mobil SHC 629, Equipment Operation : Standard Builder Operating Conditions. Bearing

Learn MoreBLAKE JAW CRUSHER - VSSUT

Before leaving, clean the equipment properly. BLAKE JAW CRUSHER. It is used for reducing run-of-mine ore or coal to a size small

Learn MoreBlake Jaw Crusher Specification - HN droled mine treatment equipment expert

Blake jaw crusher is type of jaw crusher, wherein the swing jaw is pivoted at the top. On the basis of toggle, the market has been segmented into single and double. The double toggle jaw crusher segment held the largest market share of the global jaw crusher market in and is expected to witness the highest CAGR during the forecast period.

Learn MoreJaw Crusher Explained - saVRee

The Blake crusher was first patented by Eli Whitney Blake in 1858 and it is the most common type of jaw crusher employed today. The Blake type jaw crusher has a fixed feed area and a variable discharge area. Blake type crushers come in various sizes and are commonly used for primary and secondary crushing roles. How Jaw Crushers Are Sized,

Learn MoreCharacteristics and Comparison of Four Types of Jaw Crushers

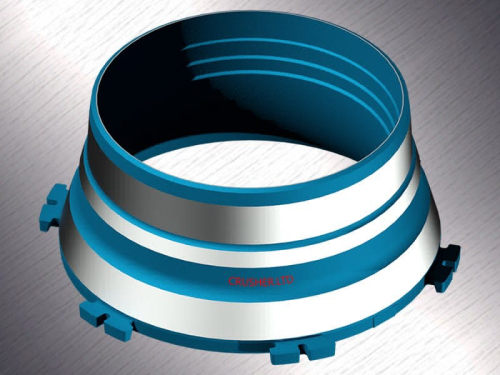

Blake jaw crusher There are two jaws in a blake jaw crusher, one is stationary and vertical, the other is movable and swing. The swing jaw reciprocates in a horizontal plane, and generally the angle between fixed jaw and movable jaw is of 20 °to30°. For blake-type crusher, its feeding area is fixed while discharging area is changeable. The

Learn Moreprocess of blake jaw crusher

Jaw crushers are classified by the method of pivoting the swing jaw (see attached figure). In the Blake crusher the jaw is pivoted at the top and thus has a fixed receiving area and a variable discharge opening. In the Dodge crusher the jaw is pivoted at the bottom, giving it a variable feed area but fixed delivery area.

Learn MoreHow does a Jaw Crusher Work - Mineral Processing

05/03/ · How does a Jaw Crusher Work - Mineral ProcessingLIKE, SHARE & Subscribe..The distinctive feature of this class of crusher isthe two plates which open and shu

Learn MoreAIM: CRUSHING AND GRINDING MAHINERY: - DTE Assam

BLAKE JAW CRUSHER: CONSTRUCTION: There are two distinct types of jaw crushers. The Blake and the Dodge. The Blake is by far.

Learn MoreDodge Crusher - Mineral Processing & Metallurgy

Their simplicity of operation and repair, combined with their ruggedness, enable them to be widely used as primary crushers. The three general forms of the jaw crusher are: Blake. Dodge and Universal. These are distinguished by the manner in which the movable jaw is moved in relation to the stationary jaw.

Learn MoreBlake Jaw Crusher Specification-HN Mining Machinery Manufacturer

Blake jaw crusher is type of jaw crusher, wherein the swing jaw is pivoted at the top. On the basis of toggle, the market has been segmented into single and double. The double toggle jaw crusher segment held the largest market share of the global jaw crusher market in and is expected to witness the highest CAGR during the forecast period.

Learn MoreWhat is a Jaw Crusher? – MEKA Crushing Equipment

All jaw crushers feature two jaws: one of which is fixed while the other moves. The working principle of jaw crushers is based on the reciprocating movement

Learn MoreAllis Chalmers Blake Jaw Crusher

Allis-Chalmers Manufacturing Company, spec sheet and operation manual for Blake jaw crusher and Dodge jaw crusher. Discusses plant layout and flowchart. 1) 54 x 74

Learn MoreBlake Jaw Crusher - 911 Metallurgist

The original Blake crusher was designed with a vertical stationary jaw. Probably the first departure from this arrangement was an 84 X 66″

Learn More