- [email protected]

- +86-21-63353309

vibration analysis of a single toggle jaw crusher mechanism

vibration analysis of a single toggle jaw crusher mechanism

Single Toggle Jaw Crusher - Vini Crushing

The CSS adjustment is very easy and fast. It uses a wedge type mechanism, which increases safety and makes adjusting CSS hassle free. The CSS can be adjusted

Learn MorePDF Study of Kinematic and Dynamic Analysis of Jaw Crusher - A Review - IJSRPDF

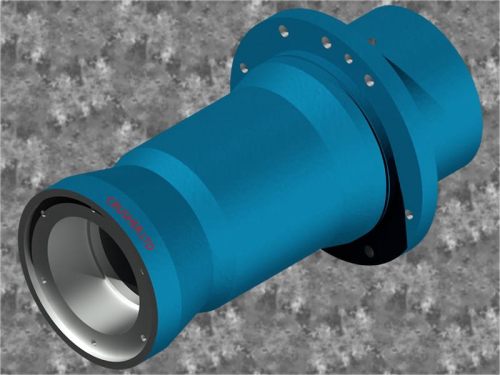

ribbed or a combination of these. The single and double toggle jaw crushers are constructed for heavy duty fabricated plates with reinforcing ribs throughout. Fixed and movable jaw faces are made up of manganese steel. The working principle of jaw crusher shown below in Figure 1 and the single and double toggle jaw crusher mechanism is

Learn MoreStudy of Kinematic and Dynamic Analysis of Jaw Crusher

The working principle of jaw crusher shown below in Figure 1 and the single and double toggle jaw crusher mechanism is shown in Figure 2 and Figure 3. Fig.1

Learn MorePDF] Analysis of the Single Toggle Jaw Crusher Force

This paper sets out to perform a static force analysis of the single toggle jaw crusher mechanism and to obtain the force transmission characteristics of

Learn MoreDesign and Analysis of Swing Jaw Plates of Jaw Crusher

For a smooth reciprocating action of the moving jaws, heavy flywheels are used in both types of crushers. &the eccentric shaft. Single toggle jaw crusher,

Learn MoreCrushing, screening, feeding and plant solutions

proud to add their new line of single toggle jaw crushers, most modern analysis techniques and features available to motion vibrating screens

Learn Morevalves | vibration analysis of a single toggle jaw crusher mechanism

PF impact crusher read more It can crush all kinds of coarse, medium and fine materials (granite, limestone, concrete, etc.) with a feed particle size not exceeding 500mm and a compressive strength not exceeding 350MPa. , Energy, cement, chemical, construction and other industries

Learn MoreMaster Thesis in Mechanical Engineering - DiVA portal

of vibration, noise and dynamic forces which can be transferred to other parts matrix-single value decomposition (PSDTM-SVD), between jaw crusher foot.

Learn MoreJAW CRUSHERS VIBRATION ANALYSIS - ResearchGate

Analyzing the vibration parameters of gas-cleaning units operated in coal and mining industry of Kuzbass. Article. Jul 2021. P. B. Gerike. Boris Gerike. V. I. Klishin.

Learn Morejaw crusher 400 x 250

Sep 14, · PE-400*600 Rock Stone Jaw Crusher (PE400X600) Features&Advantages: 1-Thich steel Plate welded body frame 2-Short toggle. 3-Easy maintenance 4- swing angle 5-Low hanging. PE-400*600 Rock Stone Jaw Crusher (PE400X600) Working Principle: The working principle of jaw crusher is very simple. The whole crushing process rely on the

Learn MoreC63 PLATE C63B | vibration analysis of a single toggle jaw crusher

Part Number Description Crusher Weight KG 00‑331‑751‑401 ANTIFRICTION CTNG MOLD RELEASE 225, 1LB SG4265 0.460 00‑333‑351‑001 ANTIFRICTION CTNG ANTI‑SEIZE COMPOUND, 1 SG4265 0.560 00‑611‑271‑548 CAP SCREW HEX .500"‑13UNC‑2AX1.500"‑AS Z036 0.004

Learn MorePDF) Analysis of the Single Toggle Jaw Crusher Force

This paper sets out to perform a static force analysis of the single toggle jaw crusher mechanism and to obtain the force transmission

Learn MoreOptimum Design and Analysis of Swinging Jaw Plate of a

Optimum Design and Analysis of Swinging Jaw Plate of a Single Toggle Jaw Crusher Thesis Submitted in Partial Fulfillment of the Requirements for the Award

Learn MoreHP300 CNTRL BOX PUSH BUTTON | vibration analysis of a single toggle jaw

spare centrifugal casting crusher vibration analysis of a single toggle jaw crusher mechanism cone crusher bowl and mantle MANTLE B M2 H3800 cone crusher design. crusher countershaft bushes ghana vibration damping sandwich mounts hp4 nut hex iso4032-m6-8-a3a ball mills compartment din 934 iso 4032 pdf.

Learn Morecrusher rotor vibration analysis of a single toggle jaw crusher

Fixed and Mobile Crusher -ZS CRUSHER. ZSDI Sand Making Rotor Centrifugal Crusher. 450KW Power , Output : 200 Ton/H Sand. Six cavity structure, Non clogging production. Mechanical

Learn MoreLT1100 CLAMP DIN3017-SA40-60-W1 | vibration analysis of a single toggle

LT110 Jaw Plate Quarry Design 1P - Bogvik Daily shrink type outerhc84145.15007-351-997-026stud 2.000-4.5unc-3a x 10.25sg54743.94007-354-558-001pinionshaft armlnr right hand 75sg5474235.87007-354-558-002pinionshaft armlnr left hand 75sg5474224.98007-354-559-001narrow arm liner 75sg5474331.12007-445-912-001eccentric bushing 1.625 throw

Learn Moretoggle plate in jaw crusher sbm crusher spare socket liner

This paper sets out to perform a static force analysis of the single toggle jaw crusher mechanism and to obtain the force transmission characteristics of the mechanism. In order to obtain force transmission metrics that are characteristic of the structure of the mechanism, such influences as friction, dead weight, and inertia are considered to

Learn Moreminyu crusher parts flow switch asm h4000 GP550 V-BELT ISO4184

Whether it's aggregates, mining, construction & demolition, recycling or road building our jaw, cone & impact crushers are ready for any job. I4C Impact Crusher. 1050mm (41.3") diameter x 1125mm (44.3") wide Impactor; 375Hp (280kW) engine; Crawler Tracks; Integrated hydraulic folding stockpiling conveyors.

Learn MoreAnalysis of the Single Toggle Jaw Crusher Force Transmission

This paper sets out to perform a static force analysis of the single toggle jaw crusher mechanism and to obtain the force transmission characteristics of the mechanism. In order to obtain force transmission metrics that are characteristic of the structure of the mechanism, such influences as friction, dead weight, and inertia are considered to be extraneous and neglected.

Learn Morejaw crusher vibration analysis pdf

Dynamic analysis of a jaw in a vibrating jaw crusher The analysis of design solutions used in vibrating jaw crushers reveals that in most cases jaw vibrations

Learn MoreJaw Crusher Working Principle - 911 Metallurgist

The jaw crusher discharge opening is the distance from the valley between corrugations on one jaw to the top of the mating

Learn More