- [email protected]

- +86-21-63353309

wear plates for impact crusher

wear plates for impact crusher

wear plates for impact crusher | crusher countershaft bushing flat

Impact Plate, Power Crusher (Model PC12071) I1270-09-03-00DB: Impact Plate, Hartl (Model 1275) H1275.10.04.00: Feed Chute Liner,Power Crusher (Model PC12071) Tip Carrier Wear Plate Center (Reversible, With Hardware Kit) B96-39-4150L: Tip Carrier Wear Plate Outer (Reversible, With Hardware Kit) 10 Ways to Get the Most Out of Your Mobile

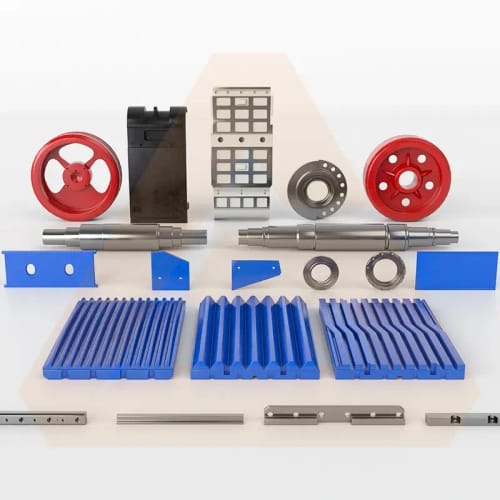

Learn MoreImpact Crusher Wear Parts For Popular Brands By MGS Casting

If you demand the peace of mind that comes with ISO 9001-certified, fully-guaranteed, and warranted replacement parts for your impact crusher, MGS Casting is your best choice! Common Name: blow bars, high manganese blow bars, high chrome blow bars, ceramics blow bars. Cast Material: Cr13,Cr23,Cr26, TIC Insert alloy steel, Ceramic. Cast

Learn MoreReplacement Wear Liners from Samscreen

If you need wear liners for your jaw, cone or impact crushing machine, Cheek plates for crushers; Side wear liners; Wear liners; Crusher wear liners

Learn MoreWear Parts - Manganese Crushtech Systems

Wearing Spares · Major wear parts include: · Jaw Crusher fixed & swing jaw, cheek plates, wedge, etc. · Cone Crusher bowl liner, mantle liner, concave ring,

Learn MoreCrusher Wear Part Photos - Kenco Engineering Inc

Kenco TCI studded wear plates, easily rotated to all wear positions, allow quick repairs in Cedarapids hammermills.

Learn MoreLiner plate - Hardox Wearparts

Custom-made liner plate made in Hardox® and Duroxite® delivers outstanding wear resistance in chutes, feeders, crushers, bins, buckets and more. Wear is mainly either sliding wear or impact wear. Duroxite® is ideal for low to moderate impact, while Hardox® can withstand all kinds of impact and keep on performing.

Learn MoreWhat Is Impact Plate |Wear Liner - Quarrying & Aggregates

The impact plate (wear liner) is the second vulnerable part in the impact crusher to the plate hammer, which bears a large impact force.

Learn MoreImpact Crusher Parts - Wear Parts For Industry | Qiming Casting

Qiming Casting can supply impact crusher wear parts with the best quality and suitable price. For impact crusher parts, Qiming Casting manufactures crusher blow bars and impact plates for popular brands with manganese steel, chromium steel, TIC inserts alloy steel, ceramic inserts, and martensitic steel. No matter which material you want, call

Learn MoreImpact crusher parts - Outotec

Available wear parts · Rotor tip sets · Back-up tips · Tip / Cavity wear plates · Upper and lower wear plates · Top and bottom lipped wear plates · Feed tube and feed

Learn Morewear plates for impact crusher | decathlon hk sale

WEAR PLATE - Hammer Crusher Parts. The impact resistance of manganese and wear resistance of ceramics are well combined. The whole life time of hammers will largely increased which doubled in normal cases.(These hammers are suitable for crushing clinkers in cement plants or similar materials which is not very hard.) Crusher Wear Parts For Jaw

Learn MoreManganese Wear Plate, Cone Crusher Spare Parts | John Heine

Jaw and Cone Crusher Liners / Manganese Wear Parts to suit most Crushers/Screens in the different grades from 14% to 22% Manganese. Very High Quality 22%

Learn Morewear plates for impact crusher | laboratory laboratory jaw crusher

Abrasion resistant wear part for vsi crusher rotor. An abrasion resistant wear plate is mountable within a rotor or a vertical shaft impact crusher to protect the rotor from material fed into the

Learn MoreHow does an impact crusher work? | RUBBLE MASTER

Impact crusher hammers, wear liners, and impact plates are consumables and need to be replaced frequently. Wear items are chewed up in the crushing process and need to be monitored and changed frequently. The higher the abrasion, hardness, and fines-content the faster the wear.

Learn Morewear plates for impact crusher | spare head bushing ceramic for micro

Horizontal Impact Crusher. Vertical Shaft Impactor; Screening. About Screening; Incline Screen Plants. 7'x20' 3-Deck Screen Plant; 6'x20' 3-Deck Screen Plant; HX900 Wear Protection; Service; Contact. ELRUS USA Contacts; ELRUS Canada Contacts; Blog. Customer Testimonials; In-Stock. Pre-Owned Inventory;

Learn MoreIMPACT CRUSHER WEAR PARTS - Precision Casting

Impact Crusher is a crushing machine that uses impact energy to crush materials. When the machine is working, motor drives the rotor rotates at a high speed. When the material enters

Learn MoreBuy Wholesale crusher wear plate at Affordable Prices

You'll get wholesale crusher wear plate that specializes in mining, with reinforced chassis, and run on more powerful engines. Whether you want to transport

Learn MoreWhat are the Materials of the Jaw Crusher Plates and Which is Better

However, due to the structure of the crusher, the opening angle between the movable and fixed jaws is too large, which is easy to cause abrasive sliding and deformation due to deformation. Insufficient hardening makes the surface hardness of the jaw plate low, short-cut abrasive cutting, and the jaw plate wears faster.

Learn Morewear plates for impact crusher | Minyu MCC51 spare part

176242 Impact plate - plain (front bolted) For crushing and screening wear parts, spares, liners & internals contact Crusher Consumables Limited. We offer OEM & aftermarket parts for a large range of machines including the 176242 Impact plate - plain (front bolted). Jaw Plate - Jaw Crusher Wear Parts. Willingindustry export stone crushers

Learn MoreCSP Impact Crusher wear parts - Cast Steel Products

932 rows · Distributor plates Wear plates Anvils and shoes Custom designed to suit your

Learn MoreWhat are the Materials of the Jaw Crusher Plates and Which is

High manganese steel. High manganese steel is the traditional material of the jaw plate of jaw crusher, which has good impact load resistance. However, due to the structure of the crusher, the opening angle between the movable and fixed jaws is too large, which is easy to cause abrasive sliding and deformation due to deformation.

Learn MoreExchanging jaw crusher wear plates - Qiming Machinery

If a jaw shim plate is used, there is no wear plate. Exchanging jaw crusher wear plates steps: Position the hook of a mobile crane vertically

Learn More