- [email protected]

- +86-21-63353309

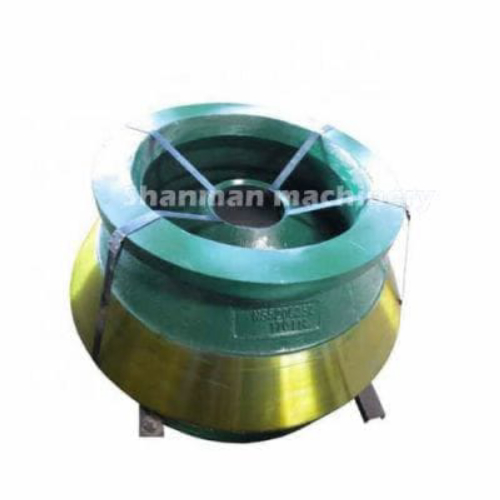

crusher liners

crusher liners

Crusher Wear Parts - Foreman Equipment Ltd

Wear occurs in all crushers, but you can help control costs by choosing the right liner configuration for the desired application. Crusher wear parts from

Learn MoreCrusher Liners, Shredder Parts, Mill Liners Foundry- Hunan JY Casting

What We Offer Hunan JY Casting manufactures crusher wear parts (cone crusher liners, crusher jaw plates, crusher blow bars), shredder wear parts (shredder hammer, grates, caps, anvils), mill liners (lifting plates, shell liners, end liners), and apron feeder pans for the most popular brands. Custom or OEM Wear Parts

Learn MoreManganese Parts - Australian Crushing and Mining

Our Manganese & Chrome liners are of the highest quality and have been known and proven to consistently out last and out Finlay Cone Crusher Liner.

Learn MoreCrusher Liners - HNS Crushing Solution

Crusher Liners. Posted on December 24, December 24, by HNS-CS. Premium crusher wear parts. HNS-CS premium manganese steel and alloy crusher liners are independently proven in mining and aggregate production to achieve and often exceed the performance of the equivalent Original Equipment Manufacturers castings.

Learn MoreCrusher Wear Parts & Liners | Wear & Impact Resistant Steel

Find crusher wear parts and liners for all types of impact crushers. Clifton Steel can make the right wear liner for the job.

Learn MoreThe Different Types of Mill Liners You Should Know

Crusher Liners When you're selecting a crusher liner, you'll need to consider the size of the feed going into the crusher. If it's too small, the bottom portion of the crusher liner will wear out faster since the crushers are coned shaped. And if the rocks are too big, they will circulate at the top.

Learn MoreCone Crusher Liners | Crushing Wear Parts

We are a leading manufacturer and supplier of quality crusher liners and wear parts, customized for each application. Get in touch with us today to learn

Learn MoreCone Crusher Liners Selection - Wear Parts For Industry | Qiming Casting

2.Crusher Liner’s Material. Cone crusher wear parts, concave and mantle, are casting by manganese steel. Mangalloy, also called manganese steel or Hadfield steel, is a steel alloy containing an average of around 13% manganese. Mangalloy is known for its high impact strength and resistance to abrasion once in its work-hardened state.

Learn MoreCone Crusher Liners - EB Castworld % Cone Crusher Liners

EB uses Mn13, Mn13Cr2, Mn17Cr2, Mn18, Mn18Cr2 to produce Cone Crusher Liners according to the customer’s working environment to effectively prevent the wear during the crushing process and greatly extend its service life. Our Experience: 13 Year Experience in Heat-resistant Steel Field. 18 Year Expertise in Wear-resistant Material Field.

Learn MoreR Crusher Wear Parts Reference Guide

crusher tools E.G. Jaw liners are subject to numerous pressure and impact stresses. Several other factors affect the wear lifetime of crusher wear parts as listed in below Diagram . Wear occurs in all crushers , however wear costs can be controlled by selecting

Learn MoreCone Crusher Liners - Tempus Steel

Producing manganese crusher liners to best suit applications such as iron ore crushing, pebble crushing in gold/copper circuits, or crushing highly abrasive

Learn MoreGyratory Crusher Liners

Increase your operation's efficiency with our expert knowledge and high-quality equipment. We are the OEM manufacturer of Gyratory Crusher Liners.

Learn MoreCrusher Liners | Cone Crusher Liners | Crushing Wear Parts

Crusher Liners CSP is a leading supplier of cast, forged, and fabricated wear solutions to OEM and aftermarket crusher operators. We have over 30 years' experience supplying crushing wear parts to global mining and mineral processing, oil sands, steel, cement, power and aggregate customers.

Learn MoreProlonging Cone Crusher Liners Working Life - Precision Casting

This occurs when the stone being crushed is forced against the liner causing it to 'work-harden'. 'Green' manganese starts off at around 25 Rockwell (250 Brinell) and can achieve a hardness of approximately 60 Rockwell (660 Brinell) after a period of work-hardening. Liner selection When selecting a crusher the bowl liner also varies in type:

Learn MoreGeometric analysis of cone crusher liner shape

Geometric analysis of cone crusher liner shape: Geometric measures, methods for their calculation and linkage to crusher behaviour. Author links

Learn MoreAR Steel Crusher Liners - Crusher Wear Liner Supplies - Ford Steel

Ford Steel offers Wearalloy 400, 450, 500, Nickel Chrome Plus Plate and Mangalloy plate up to 4-inches thick for AR steel crusher liners in impact, jaw, cone and other types of crushers. Wearalloy Superclad available for use as cheek plates too. Our company provides crusher wear liner supplies to a wide range of industries including: Sand & Gravel

Learn MoreWorld-Leading Crusher Liners - CMS Cepcor

Our premium manganese steel and alloy crusher liners are independently proven in mining and aggregate production to achieve and often exceed the performance

Learn MoreParts 48′ Gyradisc upper liner | maintenance of vertical roller

Our high quality crusher parts are made for the HP Crusher 300 and 400 series, Gyradisc Crushers 36 48 54 66, and 2 3 4 4.25 5.5 7 Cone Crushers. Symons. For more than 100 years, the ® brand of forming systems has stood as the preferred system for concrete forming around the globe.

Learn MoreBowl Liner & Mantle | Wear Resistant Crusher Parts - GTEK

Cone Crusher Mantle & Bowl Liner are used for compressing rocks and ores into small size. GTEK provides OEM interchangeable mantles & bowl liners with long

Learn MoreManganese Crusher Liners - Mining Wear Parts

Will manganese crusher liners optimise my crusher performance? Our aftermarket Manganese crusher liners for cone, jaw, gyratory, and impact crushers are cast

Learn MoreJaw Crusher Plates | Chrome White Iron

Nanhai Heavy Machinery Inc. offers high-quality products for mining like cone crusher liners, jaw crusher plates, chrome white iron protective covers, etc.

Learn More