- [email protected]

- +86-21-63353309

optimum angle for toggle plate of jaw crusher

optimum angle for toggle plate of jaw crusher

Jaw Crusher Working Principle - 911 Metallurgist

To compensate for we toggle plate, toggle seat, pitman toggle seat, and jaws additional shims must be inserted to maintain the same crusher

Learn Moreoptimum angle for toggle plate of jaw crusher C100 CAP SCRW

optimum angle for toggle plate of jaw crusher C100 CLEVIS PIN ISO2340-B-40X200X178-ST crusher pdf single jaw toggle Molinos de cocaína The jaw crusher is a single toggle jaw crusher

Learn MoreHow does a Single Toggle Jaw Crusher work? - Rubble Master

The two jaw plates are positioned in a V-shape so that the space narrows from top to bottom. The angle within the V is known as the nip angle. An elliptical

Learn MoreJaw crusher - K series - OPT Makine - DirectIndustry

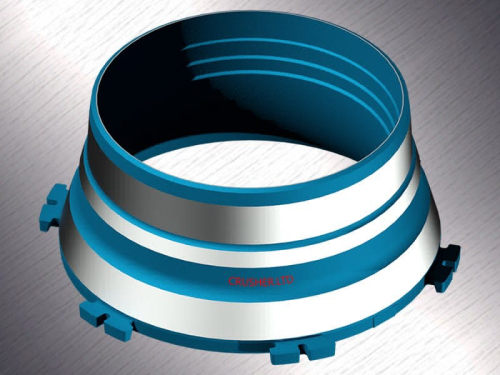

Jaw Crusher - optimal-angle toggle plate, - manganese steel casting side liners, - high-quality shaft and bearings, - and optimal design and quality

Learn Moreoptimum angle for toggle plate of jaw crusher | HP800 VIBR SNSR ASSY

CJ815 JAW CRUSHER. Mar 30, · Each jaw crusher comes with feed hopper, drive and subframe with v-belt guard and motor bracket, our unique guarding retraction arrangement and toggle plate stop. The wide range of jaw plates can be mixed and reversed to ensure optimal, versatile crushing. Your safety is our number one priority. Which

Learn Moreoptimum angle for toggle plate of jaw crusher stone crusher

The JW Series of single toggle jaw crushers is designed with a tight crushing chamber nip angle and an aggressive crushing stroke to maximize productivity. The accompanying table gives typical outputs for our range of machines, based on dry, free flowing material with a crushing work index of 16 and a bulk density of 100 lbs/cu ft (1600 kg/cu m).

Learn Moreoptimum angle for toggle plate of jaw crusher | commercial grape crusher

optimum angle for toggle plate of jaw crusher | backing compound for crushers. crusher jaw liner en aw-6082 t6 mechanical properties cepcor usa. 46 X 36 Jaw Crushers Toggle Plate/Big Capacity Jaw Crushers. Jaw crusher is ideal for primary and secondary crushing. 2. according to the wear rules of jaw plate of Standard Style Pe Series 150x250

Learn Moreoptimum angle for toggle plate of jaw crusher | bottom shell

Jaw CrushersAGGRETEK Jaw Crushers are designed for applications where cost-efficient primary reduction of hard, abrasive materials is concerned. Representing the highest technical and manufacturing knowledge, our heavy duty crushers match the most arduous crushing conditions encountered.

Learn Morejaw crushers for all your needs - Lutze Process

its size and an ideal nip angle, giving smooth material flow, toggle jaw crusher, characterized A deflector plate at the top of the moving jaw.

Learn MoreJaw Crusher Toggle Plate at Best Price in India - IndiaMART

Find here online price details of companies selling Jaw Crusher Toggle Plate. Get info of suppliers, manufacturers, exporters, traders of Jaw Crusher Toggle

Learn MoreA REVIEW - African Journals Online

DESIGN AND OPERATIONS CHALLENGES OF A SINGLE TOGGLE JAW CRUSHER: A Determination of the optimal angle of inclination of the toggle plate, development of

Learn MoreManufacturing and refurbishing of jaw crushers - RocketCDN

the job since it hardens as it wears during crusher operation. Manganese is also used in the high wear areas at each end of the toggle plates.

Learn Moremaintenance for jaw crusher

Jaw Crusher >> E Mail joyal crusherinc >> Http //joyalcrusher Work angle between toggle plate and mobile jaw increases when mobile jaw plate moves up So

Learn MoreWhat is a Jaw Crusher? – MEKA Crushing Equipment

Generally, this value is between 18 and 24 degrees in primary jaw crushers, and between 22 and 28 degrees in secondary crushers. The nip angle can be 33 degrees

Learn Moreoptimum angle for toggle plate of jaw crusher | HP4

Pennsylvania Crusher double toggle jaw crushers are superior to both the standard. Jaw Crusher Jaw Plate Standard Sizes. Incorporating a Jaques JW42 jaw crusher and a heavy duty vibrating grizzly feeder, the Finlay J

Learn Morejaw crusher best jaw plate material composition

Jaw Plate Material and Composition: Jaw Crusher Plate Component Mn14Cr2, When the moving jaw is up, the angle between lining plate and moving jaw

Learn MoreMotion and Force Optimisation in a Single Toggle Jaw

The single toggle jaw crusher is the most common crusher and uses a swing jaw in a Single Toggle Jaw tive function meant that only one optimum angle was.

Learn Moreoptimum angle for toggle plate of jaw crusher stone crusher portable

The JW Series of single toggle jaw crushers is designed with a tight crushing chamber nip angle and an aggressive crushing stroke to maximize productivity. The accompanying table

Learn Moreoptimum angle for toggle plate of jaw crusher C100 CAP

optimum angle for toggle plate of jaw crusher C100 CLEVIS PIN ISO2340-B-40X200X178-ST crusher pdf single jaw toggle Molinos de cocaína The jaw crusher is a single toggle jaw crusher characterized by attention to detail in both design and manufacture We have

Learn Moreoptimum angle for toggle plate of jaw crusher crusher copper

Name Provider Purpose Expiry Type _ok Olark Identifies the visitor across devices and visits, in order to optimize the chat-box function on the website. Session HTTP CookieConsent Cookiebot Stores the user's cookie consent state for the current domain 1 year

Learn Moremj series jaw crushers

Single Toggle MEKA Jaw Crusher is designed for applica- Jaw Crusher. TOGGLE. The optimal-angle toggle plate generates extra crushing.

Learn More