- [email protected]

- +86-21-63353309

vibrating grizzly feeder design

vibrating grizzly feeder design

Vibratory Feeder: What Is It? How Does It Work? Types Of - IQS

2022. 9. 9. · Grizzly: This is a heavy-duty screen consisting of bars, rails, Chapter 5: Feeder Trough Design. The capacity of the vibrating feeder depends on the width of the trough, depth of material flow, bulk density of the material, and the linear feed rate. This is expressed by the formula, C = WdR / 4800

Learn MoreVibrating Grizzly Feeder - CPC Crushing and Screening Equipment

Vibrating Grizzly Feeder. Feed Capacity. The capacity of vibrating grizzly feeders is calculated according to the following formula: Q=3600 x f1 x f2 x f3 x L x H x V. where, Q=Feed Capacity in (m3/hr) To obtain capacity in Tons per Hour, multiply by bulk density of the material. Qt = Q x bd bd = 1.6 Tons/m3 for sand and crushed stone; f1 is

Learn MoreVibrating Grizzly Feeder: Finger-Screen™ | General Kinematics

Features: FINGER-DECKS offer a non-blinding design compared to wire mesh screens. Optional cascading decks improve screening efficiency. Modular decks are easy to replace. Using a single vibratory motor, there is virtually no maintenance required. Will fit into your existing footprint. Can be set-up to feed into your primary crusher.

Learn MorePDF HEAVY-DUTY VIBRATING FEEDERS - PECO Sales & RentalPDF

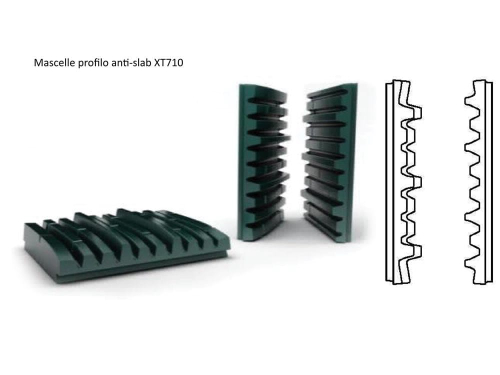

GRIZZLY BAR OPTIONS Lippmann heavy-duty replaceable grizzly bars are available in fabricated or cast steel design. They can be fixed or adjustable and bar lengths can be varied. Sections are offered in straight deck or step deck construction. Lippmann grizzly bars are tapered from top to bottom, and feed to discharge end, to provide a self

Learn Morevibrating feeder design pdf

nbsp 0183 32 Vibrating Feeder Design Handbook Hello my friends I need to handbook vibratory feeders design Thank you for your guidance Daneshvar hamid r gmail com 16th September 18 18 2 Gary Blenkhorn President Bulk Handling Technology Inc . Conveyor Dynamics Vibratory Feeder Systems.

Learn MoreVibrating Grizzly Feeders | McLanahan

Why McLanahan Vibrating Grizzly Feeders. The McLanahan Vibrating Grizzly Feeder has a history of reliability and durability. McLanahan offers feeders in five different widths to match up to

Learn MoreVibrating Grizzly Feeder / Step Deck Design

2005. 4. 29. · This way it is possible to handle a large bed depth of material moving faster in a feeder. In a vibrating grizzly feeder the exciter is fixed to give a throw angle which is larger than the vibrating feeder and less than a screen. so the stratification of material is lesser: hence we step the deck to prevent (reduce) piggy backing fines being

Learn MoreOEM manufacturer Vibrating Grizzly Feeder Design - ZFK Type Vibrating

Vibrating Mining Equipment Feature & Advantage Applications Service conditions: Requirements of Vibrating Feeder Machine for environmental conditions are as follows: 1. The ambient temperature is no more than +40℃; 2. Air relative humidity is no more than 90%; 3. It can be use

Learn MorePDF Vibrating Grizzly Feeder Advantage Series - TerexPDF

The VGF design is available with a 60" (1524 mm) grizzly section in a flat or sloped arrangement. The 20' (6.1 m) long feeders are also available with a 120" (3048 mm) grizzly section in a stepped arrangement. The grizzly bars are extra deep with an accentuated taper. This deep profile combined with the taper minimizes the

Learn MoreVibrating Feeder & Grizzly Feeder - Royal Engineering

Technical Details Royal Vibrating Feeder & Grizzly Feeder useful for continuous & uniform feeding of material from hopper to crusher / impactor / mill. Under size scalping bar arrangement in grizzly feeder. Machine body vibrate through eccentric shaft / vibratory motor. Welded steel body reinforced with heavy joints for impact loads.

Learn MoreIntrepid® Vibrating Grizzly Feeder | VGF | Superior Industries

Grizzly Section 01. Wear Liners Bolted or welded, these thick, abrasion-resistant segments protect wear areas and are easy to replace. 02. Grizzly Section Application-specific styles for dry or sticky material with an adjustable slope. 03. I-Beam Supports Manufactured 16" (406mm) from center to center to improve durability and impact resistance.

Learn Morevibro grizzly bares

grizzlies in Heavy Equipment in Canada. Road runner screening plant 3 deck 6x16, can be a wash plant 125,000 -linding stacker with grizzly 6500 -cat engine d9, with jackshaft and clutch 6500 -hough 90 loader 5000 -sander body 500 -nye trenching bucket 42 inches 2500 -plow with quick attachment from smaller loader 2000 -dyna packer , come with smooth roller and sheeps foot 6000 -50 ton float

Learn MoreVibrating Feeders for Conveying and Dosing • NetterVibration

We have developed vibrating feeders and dosing systems that provide solutions for a wide range of industries and Whatever your product and application may be, we design a totally customized feeder adapted to your needs. Netter Fritz-Lenges-Straße 3 55252 Mainz-Kastel +49 6134 2901-0 info(at)NetterVibration.com. Legal Notice

Learn Morevibrating grizzly feeder design China Manufacture, Exporter, Supplier

vibrating grizzly feeder design We now have a skilled, performance team to supply good quality services for our consumer. We often follow the tenet of customer-oriented, details-focused for vibrating grizzly feeder design Our items are commonly identified and trusted by customers and may fulfill continuously switching economic and social wants of

Learn MoreGrizzly with vibrating feeder - GrabCAD

2013. 8. 1. · Grizzly with vibrating feeder. Riaan. August 1st, 2013. One of the most common types of equipment used within the mining and quarrying industries. LHD / dump truck or

Learn MoreVibrating Grizzly Feeders | Deister Machine Company, Inc

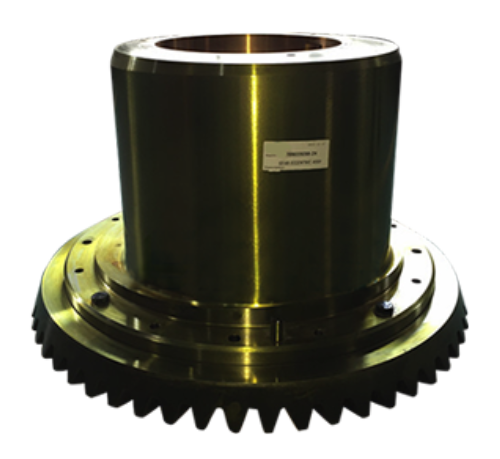

Vibrating grizzly feeders combine a pan section followed by at least one section of grizzly bars. Grizzly feeders are typically positioned under a dump hopper that is fed by haul trucks or loaders. The grizzly sections act to remove excess fines prior to the primary crusher. Download product sheet

Learn MoreVibrating Feeders

Electromagnetic vibrating feeders are offered in five standard sizes. Feeder capacity is based on sand at 100 lbs. per cubic foot. Troughs can be furnished in vee, tubular and wide flat pan designs in mild steel and 304 stainless. Typical applications include feeding to packaging, batching, mixing, drying and similar applications.

Learn MoreMcMinnville, OR

From design to construction, we are excited to help you with your next project! Let's connect virtually, or in person to discuss your project details! Call, Text or email to set up an appointment: 360-773-0940. [email protected]. McMinnville, OR 97128 [email protected] 360-773-0940 Page updated

Learn MoreGrizzly Feeders - Vibramech

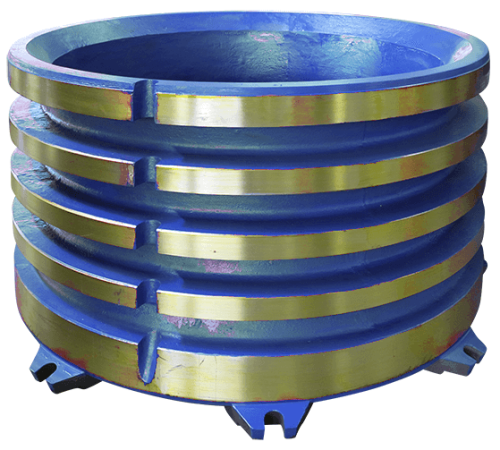

2020. 10. 6. · Vibramech Grizzly Feeders Feature: Sizes ranging in width from 0.6 - 3.0 m, ranging in mass up to 25 tons. Grizzly bars are available in cast manganese; cast manganese –CrMo alloy or wear resistant fabricated steel options. Feed pans can be lined either with rubber impact liners or wear resistant material. Installed on sub-frames where required.

Learn MoreMogensen Grizzly Feeder

Mogensen Vibrating Grizzly Feeders act as a coarse material separator while being designed to withstand the high impact forces found in aggregate primary dump loads, with a flat reinforced load area followed by sloping grizzly bar sets. Design Features. The Mogensen Vibrating Grizzly Feeder Range can be designed with various options that

Learn MoreVibrating feeder design handbook pdf - United States instructions

2022. 6. 2. · Details; Vibrating Feeder Design Handbook. the feeder and then obtained in the desired orientation. Compared with other conveying means vibrating feeders have low energy

Learn More