- [email protected]

- +86-21-63353309

valve spring manufacturing process

valve spring manufacturing process

How Springs Are Made | Coiling Technologies, Inc

Springs are generally made of hardened steel. The spring manufacturer has the option of using either pre-hardened steel before forming the spring, or they can also harden the spring after the formation process. The most commonly used spring steels are music wire, stainless steel, chrome silicon, oil tempered wire, and chrome vanadium.

Learn MoreManufacturing Process|For new customer

The treatment is carried out in advance of setting after fabrication for the purpose of improvement in fatigue strength of the spring which receives load

Learn MoreVALVE SPINGS - Accurate Springs

It is used in the Engine of any vehicle. "We manufacture Valve springs from wire dia 1.5 mm to 12 mm." The difference between regular compression Spring and the valve spring is that this spring works in high RPM and hot conditions the temperature may be around 150º C. Also valve spring has a variable pitch in some cases.

Learn MoreManufacturing | Valve Magazine

10/08/2022 · The Future of Valve Manufacturing is Already Here. Companies in the valve and control products industry are responding to a confluence of forces that are changing the landscape of manufacturing – automation, agility and digitalization to name a few. #basics. Manufacturing 7/8/2022.

Learn MoreDESIGN AND ANALYSIS OF ENGINE VALVE SPRING - IJSER

Abstract—Valve helical spring is a critical part in valve train of the IC engine. then make modification as per condition, then manufacture a.

Learn MoreSpring Manufacturing | Plymouth Spring Company

Spring Manufacturing. As a premier manufacturer of custom springs, Plymouth Spring Company, Inc., has manufacturing capabilities that reflect the comprehensive nature of the services that we provide. We operate a facility that is designed with the flexibility to provide maximum value regardless of run size-from a single prototype to high

Learn MoreProducts - American Valve Center

Valves American Valve Center is USA Division of Basso S.A. of Argentina, a valve manufacturer of automotive and heavy-duty diesel valves for distribution in North and Central America. Our High-Quality Engine Valves are manufactured for Passenger Car & Truck, Heavy Duty Diesel and High Performance/Racing applications.

Learn MoreSpring manufacturing process - Yongjia Sanhe Spring Co., Ltd

06/06/ · Spring manufacturing process, Yongjia Sanhe Spring Co., Ltd.

Learn MoreHow Are Springs Made - The Spring Manufacturing Process

21/05/ · The process of manufacturing springs is fairly straightforward, with some variations based on the type of spring being made. In their most basic variation, springs are created via a

Learn MoreUS6027577A - Manufacturing method of valve spring superior in ... - Google

according to another aspect of the present invention, this object is accomplished by providing a manufacturing method of a valve spring, comprising the steps of applying nitriding treatment to a

Learn MoreHigh-strength valve spring and it's manufacturing method

The high-strength valve spring uses, as the material, a steel containing 0.5-0.8% C, 1.2-2.5 wt % Si, 0.4-0.8 wt % Mn, 0.7-1.0 wt % Cr, balance Fe and

Learn MoreValve Spring Manufacturing with PAC Racing Prings

01/04/ · Get a sneak peak inside our Southfield Michigan Manufacturing Facility and see why PAC Racing is a leader in spring and splined bar manufacturing!

Learn Moreeffects-of-raw-material-surface-defects-on-high-strength-cr-si

Abstract- Engine valve springs are operated by the repetition from steel making/ wire/ spring manufacturing processes. These.

Learn MoreHow springs is made - material, manufacture, making, history

One process, called mechanical plating, involves tumbling the spring in a container with metallic powder, water, accelerant chemicals, and tiny glass beads that

Learn MoreMANUFACTURE MECHANICAL VALVE SPRING COMPRESSOR

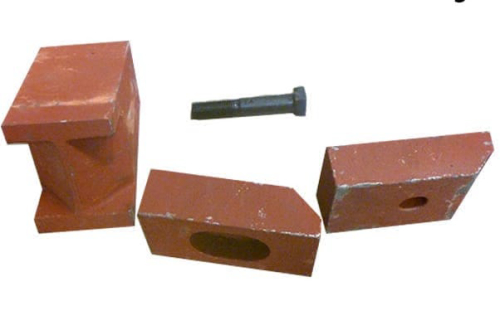

Mechanical valves in most I-type head engines are removed and re-installed using a “Valve Spring Compressor” considered as “Special Service Tool (SST).”. Removal and re-installation of valves in any automotive engines must ensure and apply safety both on the work and the worker. In this idea, the researchers planned, fabricated and

Learn MoreHigh Performance Spring Failure: A Case Study of a Valve Spring

20/07/ · The spring supplied to us was a valve spring for use in a high-performance combustion engine. Manufactured from super clean silicon chrome vanadium wire, the spring had also been exposed to variety of advanced post processing techniques (including dual shot peening) to improve the fatigue life and relaxation of the spring – a great example of

Learn More10 Steps Let You Simply Know The Process Manufacturing of ... - THINKTANK

Through the issued the manufacturing procedure card to apply the raw materials from the warehouse supervisor for machining workshop. Body, bonnet, seat, and plug, etc are machined on CNC machines. after being machined our QA inspects and measures the dimensions again. Step 4: Process Inspect

Learn MoreHigh Strength, Oil-tempered Steel Wire for Valve Springs, Manufactured

2.1 Advancement of valve spring manufacturing technologies Although large stresses are applied to the wire surfaces of coil springs, the wire surfaces inescapably have some irregularities, such as decarburized layers and flaws, which become weak points. Spring Fig. 2 Manufacturing process of oil-tempered steel wire for valve spring Wire rod

Learn MoreA Design of Manufacturing Processes for Valve-Spring

New manufacturing processes for a valve-spring retainer (VSR) are proposed by replacing the initial solid billet for commercially available thick-walled

Learn MoreBritish Valve Spring Manufacturer - Hanson Springs

Part of the spring manufacturing process at Hanson Springs' UK based spring production & supply. Technology. Order critical spring components with complete

Learn MoreValve Spring Wire

Valve springs are typically made by cold coiling of wire that has been subjected to shaving, cold drawing, hardening and tempering. Fatigue strength and sag resistance are two major factors. Tensile strength has increased over the years from 1700 MPa (247 ksi) to as much as 2150 MPa (312 ksi).

Learn More