- [email protected]

- +86-21-63353309

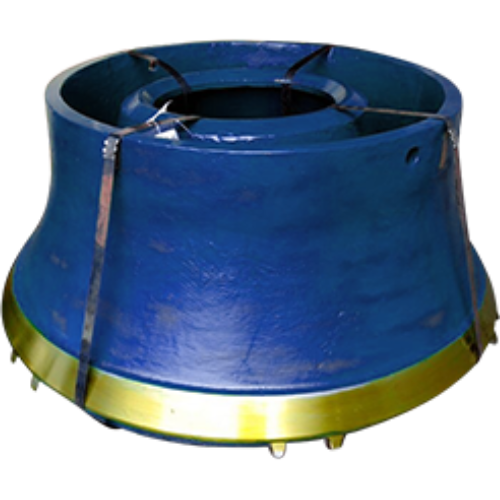

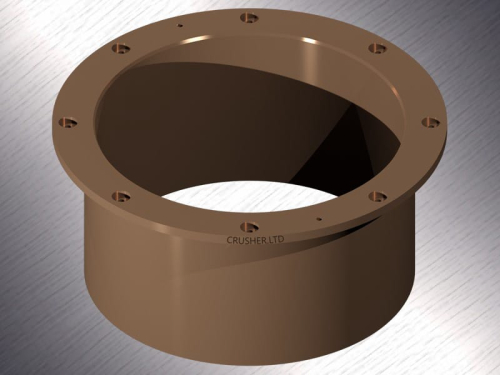

liners for cone crushers

liners for cone crushers

What affects liner life? — SRP - rockprocessing

Extending the life of liners in your cone crushers can significantly reduce maintenance costs and improve productivity, so its vital that any problems in

Learn MoreHow to Select and When to Change Cone Crusher Liners

A cone crusher's linings should be replaced when they're at least one inch thick at the bottom and have begun to crack and disintegrate. When the liners are less than a half inch thick, a 10-percent decrease in production is an indication that it's time to change them. Depending on your machine, you may even receive a reminder to change

Learn Moreliners for cone crushers | huba control pressure transmitter 5436

Cone Crushers are the earliest cone crusher in the world with over 50 years. 4829-7591, 3 ft, short head, 3′ SH bowl liner, 824. Selecting crushing chambers for cone crusher Illustrative figure of HP cone crusher liners.

Learn MoreCone crusher performance liners Wear parts and process

next level with our performance cone crusher liners. Our performance liners are specifically designed to perform in the most demanding applications.

Learn Moreliners for cone crushers | flywheel balancing procedure

Gyratory Crusher Concaves. 7″ Cone Crusher Bowl Liner. HP800 TRAMP RELEASE CYL sioux city st352 roller am30101212r cs cone crusher markets centrifugal casting

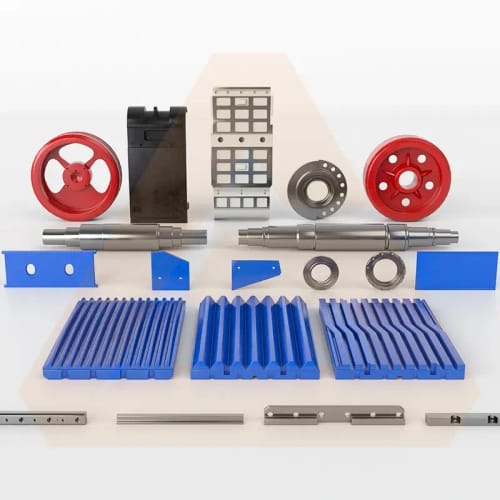

Learn MoreEXCEL™ spare parts and liners for ® HP™ cone crushers

We provide spare parts, bowl liners and mantle liners for the following ® HP -Series cone crushers: HP200™, HP300™, HP400™, HP500™, HP700™, and HP800™ Download the full component identification poster

Learn MoreHow To Select Cone Crusher Liners and When To Change Them

The Cone Crusher liner should have a well-graded feed flowing into the crushing chamber. This generally consists of: 90 to 100 percent passing the closed-side feed opening 40 to 60 percent going through the midpoint 0 to 10 percent leaving the closed-side setting Match the entire feed gradation and not only the feed shape.

Learn MoreChina Bowl Liner For Cone Crusher Factory and Suppliers

Bowl Liner For Cone Crusher - China Factory, Suppliers, Manufacturers · CJ08700-340-22U.180 · Liner Upr · ADAPTER RING.2 · Adapter Ring · 6003942 ROTOR TIPS.402

Learn MoreSelecting crushing chambers for cone crusher

Oversize feed material decreases capacity and can cause abnormal wear of the liners. Too small feed size for the cavity increases the wear of

Learn MoreGeometric analysis of cone crusher liner shape

Geometric analysis of cone crusher liner shape: Geometric measures, methods for their calculation and linkage to crusher behaviour.

Learn MoreCone Crusher Wear Parts - Columbia Steel Casting Co., Inc

For better production and longer wear life, choose Columbia cone crusher liners. · Standard, heavy-duty, and custom wear parts for all popular cone crushers.

Learn MoreCone Crusher Replacement Wear Parts - Columbia Steel Casting Co Inc

OEM liners are based on average conditions, and few cone crushers work under "average" conditions, which is why we have so many options available. Matching sets for better production Our engineers work to improve production throughout the liner life, and to arrive at even wear ratios between mantle and liner to minimize discard weight.

Learn MoreHP100 BOWL LINER C

HP100 BOWL LINER C gyratory crusher mantle repair gravel crusher inner bushing spares gyratory crusher working principle pdf Quality, Versatility, Reliability for Thousands Less Impact Crushers lippmann 2021-03-22T16:59:40-05:00

Learn MoreChina Mining Machinery Cone Crusher Parts High Mn Casting Cone Crusher Liners - China Cone Crusher Parts, Cone Crusher Liners

details about China Cone Crusher Parts, Cone Crusher Liners from Mining Machinery Cone Crusher Parts High Mn Casting Cone Crusher Liners - HENAN CRUSHTECHS MACHINERY CO., LTD. Sign In Join Free For Buyer Search Products & Suppliers

Learn MoreResearch on the Wear Behavior of the Fixed Cone Liner of a

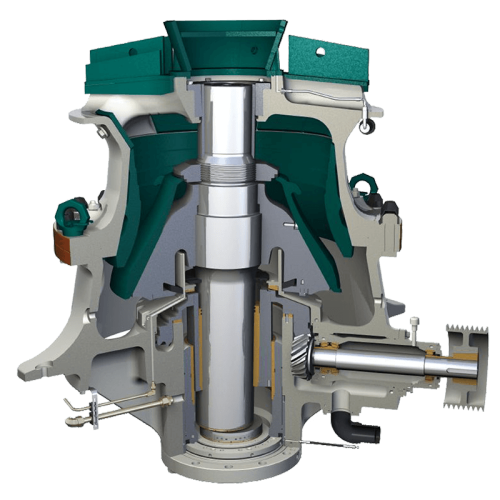

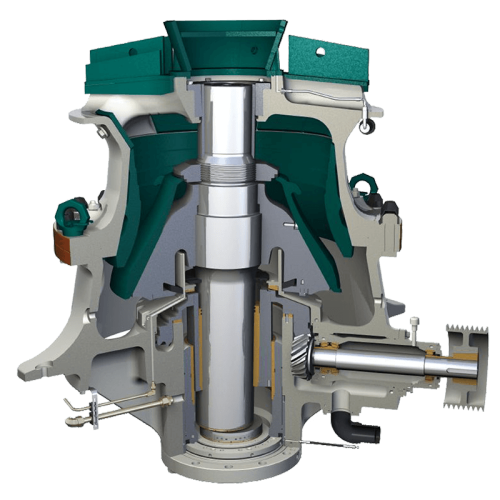

1−3) As the main crushing machine of metal ores, a cone crusher is composed of a fixed cone, a moving cone, an upper and lower frame, an

Learn MoreManganese Steel Rib and Arm Liners for Cone Crusher

Satya Alloy Castings - Offering Manganese Steel Rib and Arm Liners for Cone Crusher, Thickness: 8 - 10 mm at Rs 900/piece in Hyderabad, Telangana.

Learn MoreReplacing the liner of a HP cone crusher - Outotec

6/9 · A) Mantle - also known as head liner. B) Cutting ring - the cutting ring is not reusable, so a new ring should be installed every time the mantle is replaced. D) Padding material - its purpose is to cushion (shock absorption), not to fasten the liners. Lubrication of the head/bowl is recommended to facilitate subsequent replacement.

Learn MoreCone Crushers | McLanahan

To enhance your Cone Crusher's life and maintain optimal crushing capacities, an automatic liner change reminder is included for your convenience. When the new mantle and liners are installed, the automated reminder is reset. As the crusher operates, the system will track production capacities and calculate the liner wear rate.

Learn MoreCone Crusher Mantles & Bowl Liners - Optimum Crush

Optimum Crush® liners have led to as much as 50% increased life and/or 10% increased production. In nearly 100% of the tests conducted with Cone Crusher bowl

Learn MoreCone Crusher Liners - Hunan JY Casting

Cone Crusher Liners By Hunan JY Casting Cone Crushers have been the standard technology in cone crushing for over 70 years and Hunan JY Casting has been making cone crusher liners for this large population of crushers for nearly as long, providing better customer support than typical parts suppliers.

Learn MoreHow to Find the Right Cone Crusher Liners Manufacturer?

There are three basic types of liners for cone crushers. A standard size has a standard diameter. The "A" dimension is the width of the cone liner. It is a standard measurement for all cone liners. A larger or smaller "A" dimension increases the life of the liner and increases the capacity of the machine.

Learn More