- [email protected]

- +86-21-63353309

wear rate in crusher

wear rate in crusher

wear rate in crusher crusher wear main shaft bushing for sale indonesia

Name Provider Purpose Expiry Type; _ok: Olark: Identifies the visitor across devices and visits, in order to optimize the chat-box function on the website.

Learn MorePrediction of Cone Crusher Performance Considering Liner

Lindqvist and Evertsson [15] developed a wear model to predict the worn geometry of cone crushers. In the model, it is proposed that wear is proportional to the

Learn MorePrediction Model for Liner Wear Considering the Motion

The wear model is derived based on Archard theory and is calibrated with the measured wear profiles of the liner from a PYGB1821 cone crusher.

Learn Morewear rate in crusher | pioneer 3042 jaw crusher specs

Resolving high wear in cone crushers. The seeming high wear rate near the top of the liner set you describe begins near that same time and progressively diminishes gross output rate. This is

Learn Morewear rate in crusher | crusher machine countershaft bushes

Study of the wear behavior of limestone impact crusher. However, wear analysis shows high wear toward the centre of the blow bar and this can be attributed to non-uniform feeding of the

Learn MoreWhat is the wear profile of your crusher trying to tell you

Join this recorded webinar hosted by liner expert Greg Schellinger to learn more about how we can use the worn profiles of crushers to diagnose and improve the

Learn MoreCrusher Wear Studies for Better Productivity | Columbia Steel

Crusher wear studies by Columbia Steel take the guesswork out of cone liner, jaw plate, and gyratory wear part choices, benefiting your operation with

Learn Moreintroduces a new range of crusher wear parts

Our customers rely on wear solutions to ensure smooth crushing operations. The specific requirements of the business and process vary greatly from one

Learn Morewear rate in crusher | MP1000 SOLENOID VALVE EMDV-10-N-3A

jaw crusher wear rates - metrumbvba-metaalwerkenbe Balanced wear rates If a crusher is experiencing widely different wear rates between stationary and movable jaws, the faster wearing jaw can be cast of Xtralloy and its facing jaw of standard L68 alloy to achieve balanced we the two jaws jaw crusher liners rate5060 4448 iron giant series

Learn MorePDF R Crusher Wear Parts Reference GuidePDF

This Guide has been developed to help Dealers personnel to expand their knowledge of Crusher Wear part options & terminology and help relay this information to end users in a clear and logical manner. The Guide is broken down into following sections : 1. Wear Parts Overview 2. Jaw Crusher Wear Parts 3.• Cone Crusher Wear Parts 4.

Learn Morewear rate in crusher | flare fitting sizes

Rock crusher transmission diagram guide to muncie m20 m21 and m22 four-speed transmissions aug 03 the m22 rock crusher would come later to A method for determining the adjustment of a crusher gap setting and/or crusher rate of wear in a gyratory crusher with hydraulic adjustment of Urban Outfitters. About UO.

Learn Morewear rate in crusher 4 1 4 spare parts earl bacon crusher outer

ECA Self-movable mobile plant. 30 to 120 m 3 /h; EBA Mobile plant for medium productions. 30 to 70m 3 /h; EMA Compact plant, perfect for prefabricated. From 30 to 100 m 3 /h; MODULMIX Plant for large productions and special concretes. 80 to 150 m 3 /h

Learn MoreVertical Spindle Mill Wear Rates - Stone Crushing Machine

Vertical Spindle Mill Wear Rates. how to repair vertical mill how to repair vertical mill-- CMS (Crusher Machine Sale In results 1 25 of 32 milling machine repairs including spindle cement vertical mill wear rate .

Learn Morewear rate in crusher

wear rate in crusher Expected or Typical "life span" of wear parts of jaw crusher. For limestone aggregate cost of wear/spare parts was 3-7% of new plant cost per 2000 hours, for medium

Learn MorePDF Monitoring wear rates in crushers - MaptekPDF

the crusher of both the design and the actual scanned area. Further analysis The study revealed uneven we the crusher lining. Quadrants where material was tipped into the crusher showed higher wear. Data for one quadrant indicated that trucks were not stopping parallel to the crusher dump box, exacerbating wear at this point.

Learn MoreImpact Crusher - an overview | ScienceDirect Topics

The speed of the rotor varies between 500 and 3,000 rpm. Due to the high rate of we these machines (wear can be taken up by moving the hammers on the pins)

Learn MoreImproving the Wear Resistance of Key Components in a Crusher

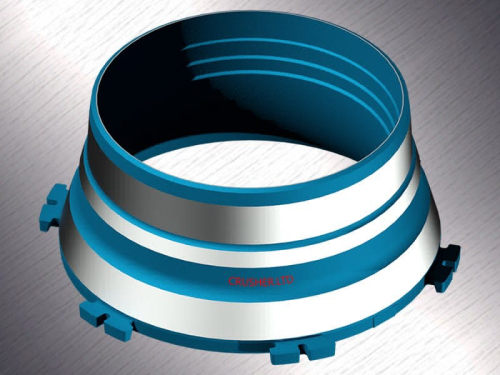

At Stoilensky GOK, a conical crusher is used on the rock [1–3].The crushing chamber consists of a mobile cone 4 and an immobile annular lining 3.The cone is attached to primary shaft 6, while the immobile ring is attached to upper bowl 2.The upper part of the primary shaft is supported by the bearing of crosspiece 1; the lower end sits in eccen-tric 5.

Learn Morewear rate in crusher 341 jaw crusher main board price bearing

wear rate in crusher. Crushers. I4C Impact Crusher; J40 Jaw Crusher; J45/J45R Jaw Crusher; J50 Jaw Crusher; C2 Cone Crusher; C2R Cone Crusher; C3 Cone Crusher; C3R Cone Crusher I4C Impact Crusher. 1050mm (41.3") diameter x 1125mm (44.3") wide Impactor; 375Hp (280kW) engine; Crawler Tracks;

Learn MoreCone crusher performance liners Wear parts and process

Performance cone crusher liners from not only provide consistent, high-rate production and longer wear life, but they also protect your crusher

Learn Morewear rate in crusher | GP500 CONCAVE MF

The liner wear directly affects the cone crusher performance and and the wear rate is proportional to the pressure and the sliding Exactly how to pick the right crusher wear parts foundry. The crusher wear liners in this product contain around 11 % Manganese (Mn), 1 % Carbon (C), and also balance iron (Fe). It can have a capacity of

Learn MoreR Crusher Wear Parts Reference Guide

This Guide has been developed to help Dealers personnel to expand their knowledge of Crusher Wear part options & terminology and help relay this information to end users in a clear and

Learn More