- [email protected]

- +86-21-63353309

gyratory crushers sizes

gyratory crushers sizes

Torque Analysis of a Gyratory Crusher with the Discrete

selection of the minimum resolved particle size are given. Keywords: comminution; gyratory crusher; discrete element method; torque;

Learn MoreCrushing Products Size and Shape -What to Expect

Crusher-Setting, Product-Size. Gyratory and jaw crushers are always rated at certain

Learn MoreGyratory Crusher Feed Size

Maximum feed size (mm) Typical maximum product size (mm) Typical capacities (t/h) Gyratory crusher: Primary: 1500: 200-300: 1200-over 5000: Jaw crusher: Primary: 1400: 200-300: Up to 1600: Horizontal impact crusher: Primary/secondary: 1300: 200-300: Up to 1800: Cone crusher: Secondary 450 60-80Up to 1200: Cone crusher

Learn MoreJaw Crusher Manufacturer | CITIC HIC

Gyratory Crusher; Jaw Crusher; Semi-mobile Gyratory Crushing Station Model, Feed opening, Max. feed size, Discharge opening, Crushing capacity

Learn MoreGyratory Crusher Explained - saVRee

Gyratory crushers were invented by Charles Brown in 1877 and further developed by Gates in 1881 (they were commonly referred to as a ‘Gate’s crushers’ in the early years). A primary

Learn MoreGyratory Crusher Sizes

Gyratory Crusher Sizes. 11 gyratory crushers can accept 810 moisture in operation but the fine content should be preferably less than 10 the crushing action in gyratory crushers is regarded as rings or helics spirals of feed down through the crusher of which a single section may be regarded as similar to the jaw crusher get price.

Learn MoreDifferent types of crushers for distinctive needs - Outotec

Cone crushers resemble gyratory crushers from the technological standpoint, but unlike gyratory crushers, cone crushers are popular in secondary, tertiary, and quaternary crushing stages. Sometimes, however, the grain size of the processed material is small enough by nature and the traditional primary crushing stage is not needed.

Learn Moreid/nama gyratory crusher of capacity 3b20.md at main - GitHub

power requirement by cone crusher educationcarein.Crushers and Equipment Technology in Mining Crushers,A cone crusher is similar in operation to a gyratory

Learn MoreGyratory Crusher

Model Inlet size (mm) Outlet size (mm) Capacity (t/h) Power (kw) Dimensions(mm) HGT 4265 1065 140-175 2015-2875 400 3940×4170×6900 HGT 5065 1270 150-175 2400-2940 400 4460×4430×7610 HGT 5475 1370 150-200 2890-3490 450 4930×4925×8410 HGT

Learn MoreCrushers - All crusher types for your reduction needs

Cone crushers resemble gyratory crushers from technological standpoint, but unlike gyratory crushers, cone crushers are popular in secondary, tertiary, and quaternary crushing stages.

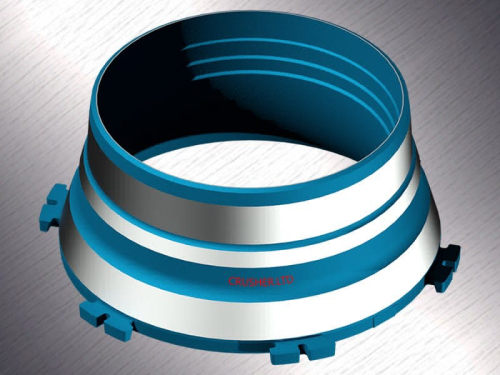

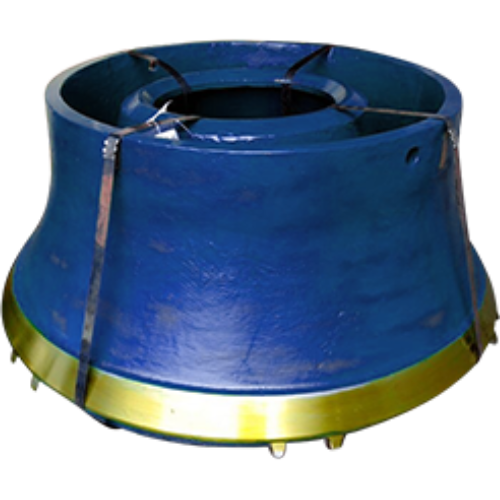

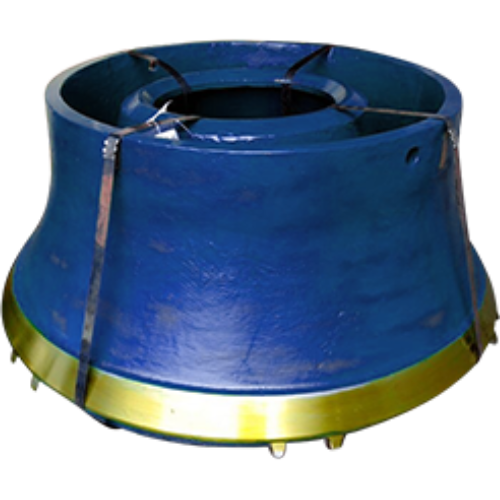

Learn MoreGyratory Crusher Liners

Maximise your crushing productivity with proven Gyratory Crusher Liners. Our Gyratory Crusher Liners are focused on serving you and your operation and are tailored specifically to your needs and goals. Rely on our knowledge, engineering and technology to improve

Learn MoreGYRATORY-CRUSHERS.pdf - RocketCDN

The crushing head and gyrations per minute are the same as those used on equivalent sized primary crushers. However, the concaves and crusher frame or shell are

Learn MoreGyratory Crusher - an overview | ScienceDirect Topics

The gyratory crusher can, just like a jaw crusher, accept boulder sizes close to 1.5 m (for the largest equipment).This crusher can handle products with a Mohs hardness that is not

Learn MoreCrusher - Wikipedia

A gyratory crusher is one of the main types of primary crushers in a Gyratory crushers are designated in size either by the gape

Learn MorePDF 2. Gyratory CrushersPDF

Mechanical Features General The majority of gyratory crushers that are currently manufactured are large units, i.e., 42 in. and larger gape, and are of the short shaft type. Generally the units are of the hydraulic supported type although there are specific applications where the spider suspended type is more desirable.

Learn Morejaw crusher and gyratory crusher | Henan Deya Machinery Co., Ltd

7/29 · A Jaw Crusher reduces large rocks by dropping them into a flat “V” shaped space created between a fixed surface and a movable surface. The compression is created by forcing the rock against the stationary plate. The opening at the bottom of the jaw plates is the crusher product size gap. The rocks remain in the jaws until it is small enough

Learn MoreTypes of Crushers: What You Need to Know

After materials receive their first round of crushing, they are fed into a secondary crusher to be reduced further. Average material sizes range from 350mm to

Learn MoreGyratory Crusher-MECRU

The gyratory crusher has a huge output and is often used for coarse crushing operations of large enterprises or large production lines. It can crush the raw material ore produced by drilling and blasting to a suitable particle size for subsequent crushing process or beneficiation process. It is the key to the entire process.

Learn MorePDF TECHNICAL NOTES 5 CRUSHERS - Mineral TechPDF

Maximum size that can be accepted into the crusher is approximately 80% of the gape. Jaw crushers are operated to produce a size reduction ratio between 4:1 and 9:1. Gyratory crushers can produce size reduction ratios over a somewhat larger range of 3:1 to 10:1. The primary operating variable available on a crusher is the set and on jaw and

Learn MoreGyratory Crusher Wear Plates

60 x 89; 60 x 113NT/UD. The option to customise. We provide tailored solutions for any model and size of equipment that may

Learn MoreGyratory Crusher | Jaw Crusher Manufacturer | CITIC HIC

New Type Gyratory Crusher, PXZ Ⅲ Series Model Feed opening Max. feed size Discharge opening Crushing capacity Crusher weight mm mm mm t/h t PXZ 42-65Ⅲ 1100 900 140-175 2300-5250 123 PXZ 50-65Ⅲ 1270 1050 150-175 2400-6350 159 PXZ 54-75Ⅲ

Learn More