- [email protected]

- +86-21-63353309

grate kiln

grate kiln

Grate-Kiln System for iron ore pelletizing - DirectIndustry

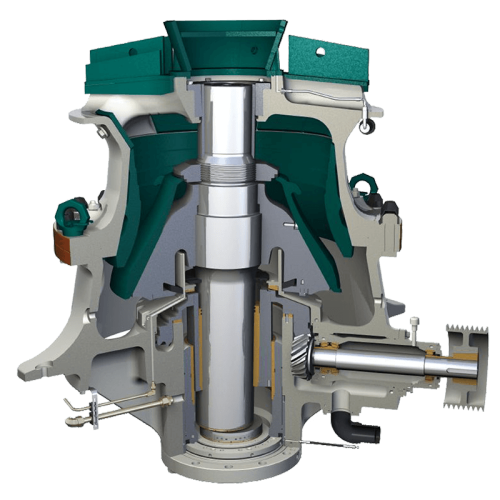

The kiln is a single chamber with an open feed end connected by housing to the grates preheat furnace Through this connection is the inflow of material to the kiln and outflow of kiln gas to the preheat furnace. The kiln's discharge end is open and connected to the cooler by a firing hood. Through the firing hood, pellets flow from the kiln to

Learn MoreCement kiln - Wikipedia

Cement kilns are used for the pyroprocessing stage of manufacture of portland and other types of hydraulic In this case, the water content of the pellets is 17-20%. Grate preheaters were most popular in the 1950s and 60s, when a typical system would have a grate 28 m long and 4 m wide, and a rotary kiln of 3.9 x 60 m, making 1050 tonnes per

Learn MorePelletization Solutions

2020. 1. 16. · Grate-Kiln system Consistent pellet quality, lowest operating costs The Grate-Kiln induration machine is composed of three separate pieces of equipment; the Traveling Grate,

Learn MoreGrate Cooler | Clinker Cooler, Cement Cooler | Cement Plant

Grate cooler. Production Capacity: 600~10000 t/d. Heat recovery rate: ≥72%. Application: cement, silicate products, new building materials, etc. . The grate cooler is a quenching type cement cooler apply for the cement manufacturing plant. According to the movement mode of the grate, the grate cooler can be divided into three

Learn MoreIron Ore Pellets and Pelletization Process – IspatGuru

2014. 11. 26. · Pelletizing of iron ore was started in the 1950s to facilitate the utilization of finely ground iron ore concentrates in steel production. For the pelletizing of iron ore there are two main types of processes namely, the straight travelling grate (STG) process and the grate kiln (GK) process. In the STG process, a stationary bed of pellets is

Learn MoreGrate Kiln For Sale – Grate Kiln System | AGICO Grate Kiln

The grate kiln system consists of three independent machines: traveling grate, rotary kiln, and annular cooler. Operators can separately control the running speed of the three devices. It

Learn MoreGrate Kiln - China Factory, Suppliers, Manufacturers

Grate Kiln Manufacturers, Factory, Suppliers From China, We give priority to quality and customer pleasure and for this we follow stringent excellent control measures. We've got in-house testing facilities where our items are tested on every single aspect at different processing stages. Owning to latest technologies, we facilitate our clients with custom made creation facility.

Learn MoreTravelling Grates&Chain Grate&wear plate on Grate-kiln

2022. 5. 28. · Casting process: Shell mold precision casting. 2. Steel grade: 1.4777 1.4848 1.4837. 3. Dimensional Tolerance of cast: DIN EN ISO 8062-3 grade DCTG8. 4. Geometrical Tolerance of cast: DIN EN ISO 8062 – grade GCTG 5. 5. Application: Wear Parts on Grate-kiln.

Learn MoreCement Kilns: Grate Coolers

The first form of grate cooler used on British kilns was the Bucket Grate. The cooler was built into a greatly-enlarged kiln hood, with length about 1.9 times the kiln diameter, and width 15% greater than the length. A concave grate-plate occupied the entire base, with a pressurisation chamber below.

Learn MoreGrate-Kiln System for iron ore pelletizing - Automation

Kiln drive components Equipment description Grate The traveling grate is a conveyor that transports balled iron ore concentrate through cross-flow processing zones. The conveying

Learn MoreIron Ore Pelletizing Grate-Kiln System Brochure - DirectIndustry

Energy efficiency The Grate-Kiln® induration machine is composed of three separate process pieces of equipment. The traveling grate is used primarily to dry and preheat green balls for feeding into the rotary kiln, where they are indurated. Once the green balls are made they are spread out evenly across the grate.

Learn MoreGrate Kiln Stock Photos, Pictures & Royalty-Free Images - iStock

Search from Grate Kiln stock photos, pictures and royalty-free images from iStock. Find high-quality stock photos that you won't find anywhere else.

Learn Moreto supply large-scale grate-kiln pellet plant to India - SteelOrbis

Finland-based global engineering and technology company Outotec Corporation has announced that it will supply a large-scale grate-kiln pellet plant to an Indian customer in Odisha. The value of the order is estimated to be in the range of €30-40 million. According to the statement, the grate-kiln plant with an annual production capacity

Learn MoreContributions to The Technology Comparison Between Straight Grate and

The grate-kiln process, which has been inspired from furnaces designed in the cement industry, uses three distinct pieces of equipment to carry out the induration process: a preheat travelling grate, a rotary kiln, and an annular or straight cooler. Drying and preheating of the green pellets is accomplished on the preheat grate,

Learn MorePDF Pelletization SolutionsPDF

The Grate-Kiln induration machine is composed of three separate pieces of equipment; the Traveling Grate, the Rotary Kiln, and the Annular Cooler. Independent variable speed control of drying/preheating, induration, and cooling allows process flexibility to adjust to changes in concentrate feed.

Learn Morekiln iron–ore pellet induration process - PDF Free Download

GRATE/KILN PELLET INDURATION The Allis-Chalmers grate/kiln process employs a furnace with a moving grate for drying and preheating the J.A. THURLBY is Principal Research Scientist, Division of Mineral Engineering, Commonwealth Scientific and Industrial Research Organisation, Clayton, Victoria, Australia. Manuscript submitted June 24, 1986.

Learn Moregrate kiln - English definition, grammar, pronunciation, synonyms and

For existing plants, both straight grate and grate kiln systems, it is difficult to obtain the operating conditions necessary to suit an SCR reactor. EurLex-2 Bypass dust: Dust discarded from the bypass systems of the suspension preheater, precalciner and grate preheater kilns , consisting of fully calcined, kiln feed material.

Learn MoreGrate Cooler - Clinker Cooler | AGICO Grate Cooler In Cement Plant

There are various types of clinker coolers developed before grate cooler: shaft cooler, rotary cooler, etc. Compared with them, grate cooler is the most suitable one for cement production lines with high outputs and usually designed for large cement kiln capacity that up to 10000 t/d. Distinct advantages of grate cooler:

Learn MoreKilnSimu - GTT-Technologies

With KilnSimu it is also possible to build and simulate a flowsheet containing several different kinds of unit operations commonly used with rotary kilns. These are: Cooler, Calciner, Cyclone, Mixer and Splitter. Cooler is a grate kiln where air is blown from the bottom of the cooler through the grates and the bed in a cross-current fashion.

Learn MoreGrate-Kiln Process - Iron Ore Pelletising - PDF Free Download

CONCLUSION The Grate-Kiln system provides the lowest cost method of making high quality pellets. High availability, low fuel including that of Coal burning capability, low power use and low maintenance costs make it the system of choice for Iron ore pellet producers and users be it Hematite or Magnetite ore. TRANSLATE

Learn MoreGrate Kiln For Sale - Grate Kiln System | AGICO Grate Kiln Pelletizing

The grate kiln system is mainly applied for the indurating and cooling stages. It has the features of large scale, continuous, high efficiency, and great sealing. The grate kiln system consists of three independent machines: traveling grate, rotary kiln, and annular cooler. Operators can separately control the running speed of the three devices.

Learn More