- [email protected]

- +86-21-63353309

cone crusher liner change

cone crusher liner change

how to prolong cone crusher replacement working life?

This post explains a method to reduce crusher replacement costs by casting crusher liners. However, the process has been perfected in recent

Learn MoreCone Crusher Wear Parts - Columbia Steel Casting Co., Inc

OEM liners are based on average conditions, and few cone crushers work under replacement for zinc in both portable and permanent crusher applications.

Learn MoreLiner change solves heat issue; improves production and

its cone crusher led a copper mine to contact FLSmidth. A new liner profile solved the challenge and improved the site’s overall performance. WE DISCOVER POTENTIAL Results at a glance 30% increase in production Liner life doubled 32% increase in availability 18% reduction in heat generation M 05-19 0000-9-ENG Liner change solves

Learn MoreWhen do you change cone liners? - ELRUS Aggregate Systems

Click the image below to earn more. ELRUS Manganese Cone Liners. Topics: Downtime, crusher spare parts, gravel crushing and screening costs,

Learn Morecone crusher liner change | differential pressure switch for water pump

As cone crusher liners wear, the operator threads the bowl inwards, price of the liner change you should consider changing the liners. Wholesale Price Cone Crusher Liners. 3. When changing the lower copper sleeve of the movable cone and the eccentric sleeve bushing, you must first check whether the inner diameter of the movable

Learn MoreCone Crusher Mantles & Bowl Liners – Optimum Crush

Our relationship with multiple foundries minimizes risk and ensures the best price with liners made to our quality requirements. Optimum Crush® liners have led to as much as 50% increased life and/or 10% increased production. In nearly 100% of the tests conducted with Cone Crusher bowl liner, they have met or exceeded the current product.

Learn MoreWhen to change Cone Crusher liners - Cast Steel Products

A good indication the Cone Crusher liners need to be changed is when there is a 10% or more drop in production level or throughput. Liner thickness Depending on the application, If the

Learn MoreCone crusher basics in 4 minutes — SRP

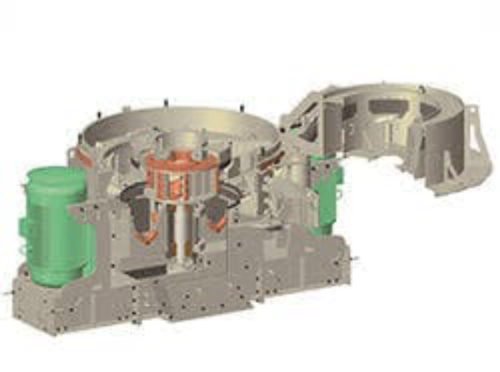

Cone crusher basics in 4 minutes. This is the starting point for understanding how cone crushers work – and how they can make your mine or quarry more

Learn MoreCSP Cone Crusher Wear Parts - Cast Steel Products

CSP Cone Crusher wear parts offering consists of replacement and custom design wear parts for cone crushers, including: Mantles, Bowls, Concaves, Feed Cones, Main Frame Liners, Protection Cones, Arm guards, Torch rings, Distributor caps, and Crusher backing. FEATURES & BENEFITS

Learn MoreCone Crushers | McLanahan

When should I replace my Cone Crusher liner? If the liner is wearing evenly throughout the chamber, you should consider changing out the manganese when it has worn down to about 1" (2.5 cm) thick at the bottom. At about 3/4" to 5/8" (1.9 to 1.6 cm) thick, the manganese will crack, causing the backing material to begin to disintegrate.

Learn MoreResearch on the Wear Behavior of the Fixed Cone Liner of a Cone Crusher

May 05, · Taking reducing the wear of the fixed cone liner of a cone crusher as the starting point, the movement and geometry parameters of the cone crusher are studied using the discrete element method. but the change trend is different. The effect of the dynamic friction coefficient on the repose angle is obviously greater than that of the static

Learn MoreChina Cone Crusher Liner Change Manufacturers and Suppliers - Factory

Cone Crusher Liner Change - Manufacturers, Suppliers, Factory from China Our target is to consolidate and improve the quality and service of existing products, meanwhile constantly develop new products to meet different customers' demands for Cone Crusher Liner Change, H8800 Cone Crusher Wear Parts , Nerdberg Cone Crusher Spare Parts , 3

Learn MoreHow To Select Cone Crusher Liners and When To Change

The Cone Crusher liner should have a well-graded feed flowing into the crushing chamber. This generally consists of: 90 to 100 percent passing

Learn MoreChanging of crusher liners

Using crusher backing material to help change liners of 1000 maxtrac cone crusher.

Learn Morecone crusher liner change | puzzolana 200 tph cone crushers shaft sleeve

cone crusher liner change. Analysis of the Wear Failure of Cone Crusher Liner at. The moving cone (liner) we sampled was just removed from the cone crusher and shipped back in time. The broken cone crusher liner is cut into large samples by oxygen-acetylene flame, and 4 samples are taken from top to bottom. The size of the sample should be such

Learn Morecone crusher liner change | LT110 CAP SCRW HEXSCKTHD ISO4762-M5X130-12.9

How to change cone crusher liners? Normally, there are 6 steps to change cone crusher liners: On the first collection of brand-new linings, position a mark on the modification cap chauffeur ring where the pinion tooth reaches a motorist ring tooth when the target crusher setting has actually been accomplished.

Learn MoreChange Cone Crusher Wear Parts - Qiming Machinery

Situation 1:Normal Abrasion. In order to avoid damage to the liner seating surfaces of the crusher head or bowl, wear parts must be replaced

Learn MoreCone Crusher Liners: What To Choose And When To Change

Cone Crusher Liners: What To Choose And When To Change Cone crushers were invented over a century ago for secondary, tertiary and even the removal of quaternary materials. Like other

Learn MoreREAL-TIME OPTIMIZATION OF CONE CRUSHERS - CORE

The wear of crusher mantle liners and screen cloths dramatically affects the products and the performance of the crushing process, Svedensten [46]. Changing.

Learn MoreApplication guide ® MP Series™ cone crusher wear

Installation of new bowl liner • Make sure bowl liner is centered in bowl • Replace wedges (shim as needed) • Tighten in criss-cross pattern: check seat area with feeler gauge, pour backing if required and place insulation around wedges Mantle removal 1. Remove feed plate (feed cone) 2.

Learn MoreHow To Select Cone Crusher Liners and When To Change Them

Dec 27, · How To Choose. 90 to 100 percent passing the closed-side feed opening. 40 to 60 percent going through the midpoint. 0 to 10 percent leaving the closed-side setting.

Learn More