- [email protected]

- +86-21-63353309

jaw crusher working principle

jaw crusher working principle

Jaw Crusher Working Principle - Gravel Mill

Working part of jaw crusher is two pieces of jaw plate, one is fixed jaw plate (fixed jaw), vertical (or slightly upper camber) fixed in the front wall of the body, and the other is movable jaw plate

Learn MoreJaw Crusher Working Principle

Jaw Crusher Working Principle Mar. 18, 2022 . The movable jaw has its maximum movement at the top of the crushing chamber, and minimum movement at the discharge point. The motion is, however, a more complex one than the Dodge motion, being the resultant of the circular motion of the eccentric shaft at the top of the swing jaw. combined with the

Learn MoreMining Industry: What Is Jaw Crusher's Working Principle?

Jaw crusher The motor transmits power through belt, drives the moving jaw do periodic motion to the fixed jaw surround the eccentric shaft. The angle between toggle plate and moving jaw increases when moving jaw moves up. So the moving jaw closes to the fixed jaw, and the staff will be crushed in multiple ways.

Learn MoreJaw Crusher Types

Jaw Crusher Working Principle. Jaw crushers are a type of crusher with a unique system. Jaw crusher, which is a very strong type of crusher, performs the

Learn MoreWhat is a Jaw Crusher? - MEKA Crushing Equipment

All jaw crushers feature two jaws: one of which is fixed while the other moves. The working principle of jaw crushers is based on the reciprocating movement of the movable jaw that compresses and crushes the rock or ore between itself and the fixed jaw, as the material enters the zone between the jaws.

Learn MoreWorking principle of rotary disc crusher - Shanghai Company

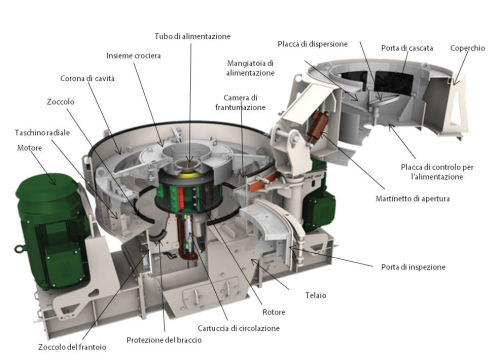

The working principle of the rotary disc crusher combines advanced technology and manufacturing technology in traditional technology to carry out energy saving, emission reduction and recycling work. The working principle of the rotary disc crusher itself requires high technical content and integration, with the mining company.

Learn MoreWorking Principle Of Crushers | Crusher Mills, Cone Crusher, Jaw Crushers

Jaw Crusher: Range, Working Principle, Application - Jaw crushers are used as primary crushers, or the first step in the process of reducing rock. They crush primarily by using compression. The rock is dropped between working principle of crusher -

Learn Morejaw crusher working principle | Henan Deya Machinery Co., Ltd

7/29 · A Jaw Crusher reduces large rocks by dropping them into a flat “V” shaped space created between a fixed surface and a movable surface. The compression is created by forcing the rock against the stationary plate. The opening at the bottom of the jaw plates is the crusher product size gap.

Learn MoreSingle Toggle vs Double Toggle Jaw Crusher - JXSC Machine

The jaw crusher usually the primary crusher for in the crushing plant, to reduce the large ore lump to smaller particles for the next stages of

Learn MoreWorking Principle Cone Crusher | Crusher Mills, Cone Crusher, Jaw Crushers

Working Principle of the Cone Crusher. When the cone crusher is working, the engine rotates around a fixed point driven by the belt wheel or the coupling. Working Principle of Cone Crusher (3D)= Heavy Industry Videos Display Our machines and production plants remain good performance and durability during tough working condition. >>

Learn Morejaw crusher principle

About Press Copyright Contact us Creators Advertise Developers Terms Privacy Policy & Safety How works Test new features

Learn MoreJaw Crusher Working Principle Pdf Manufacture and Jaw Crusher Working

Jaw Crusher Working Principle Pdf - manufacturer, factory, supplier from China. Industrial Manganese Steel Jaw Crusher Spare Parts. Well Transported Manganese Steel Jaw Crusher Spare Parts. Stone Crusher Simple Structure Vibrating Feeder. Iron Ore Slag Rod Mill Crusher Machine.

Learn MoreJaw Crusher Working Principle - Conmix Crusher

The moving jaw of the single toggle jaw crusher moves elliptically. A pendulum motion is being carried out by the double toggle jaw crusher. The crushing force is produced by an eccentric shaft. Then it is transferred to the crushing zone via a toggle plate system and supported by the back wall of the housing of the machine.

Learn MoreJaw Crusher: Range, Working Principle, Application

Jaw crushers are used as primary crushers, or the first step in the process of reducing rock. They crush primarily by using compression.

Learn Moredouble toggle jaw crusher working principle | reciprocating grate cooler

double toggle jaw crusher animation and working principle The working principle of the jaw crushers is very simple. Powered by a diesel or gas motor, the j. Double Toggle Jaw Crusher. Best Kinematics. Optimized Crusher cavity, effective nip angle, kinematics and operating parameters fully guarantee the excellent productivity for which MAXWELL

Learn MoreJaw Crusher Working Principle - 911 Metallurgist

A single-toggle pivots at the base of the swing plate which is causing the jaw's arc-like motion. The rock pinching resulting from its flowing/

Learn MoreCrushing technology - kleemann

Jaw crushers operate according to the principle of pressure crushing. The crushed material is crushed in the wedge-shaped pit between the fixed crusher jaw and

Learn MoreComputer Aided Design of Jaw crusher” - ethesis

1.3 Working Principle: The mechanism of jaw crusher is based on the concept “crushing without rub ”. Jaw crushers consist of two jaws. One

Learn MoreJaw Crusher Working Principle Of Jaw Crusher

The work method of jaw crusher animation working principle of jaw crusher The motor drives the mobile jaw up and down through eccentric shaft. The angle

Learn MoreWhat is a Jaw Crusher | Advantages, Types, Parts and

The working principle of jaw crushers: When working, the motor drives the belt and pulley to move the movable jaw up and down through the eccentric shaft.

Learn Morejaw crusher_working principle_stone crusher

Working principle. Jaw crusher mainly consists of fixed jaw plate, mobile jaw plate, protection plate, mobile jaw bar, and so on. In operation, it motivates with electrical motor and then rotating eccentric spindle and jaw plate. Material will be crushed by squeezing, cracking, impacting, and crushing, and finally qualified material will be

Learn More