- [email protected]

- +86-21-63353309

mention the purpose of jaw plates

mention the purpose of jaw plates

Jaw Plates - SHANVIM

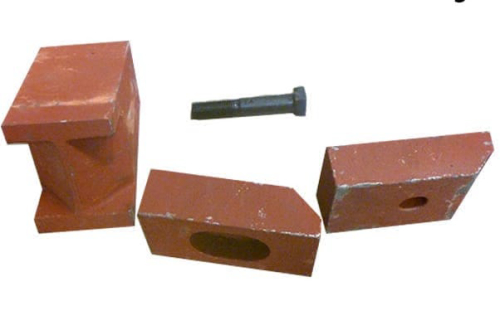

JAW CRUSHER PLATE-JAW LINER. Jaw Plates or Jaw Dies are the most frequently replaced wear parts of the jaw crusher, so the quality of the jaw die is one of the most important factors that determine the crushing efficiency and operating time. A set of jaw plates are composed of the movable (swing jaw) and fixed jaw plate (stationary jaw).

Learn MoreHow Much Do You Know About Jaw Plates For Jaw Plates?

11/14 · 3.Inspection of Jaw Plates: On Nov.3, ,all inspection for jaw plates was done. The sizes of jaw plates are 997x 698 x 71mm, 1000x778x68mm. The material grade of jaw

Learn MoreGrooveLock Jaw Plates | Vise Jaws & Jaw Plates | Kurt Workholding

Kurt GrooveLock 6″ Reversible Step Jaw Plate – D60-316 D60-316 $ 181.00 Kurt Jaw Plate w/ Groove – D40-315 D40-315 $ 72.00 Be a Kurt Insider Sign up to receive our Kurt newsletter to be the first to learn all about our latest innovations, industry trends BE A

Learn MoreWhy is it important to use vice jaw plates? - Answers

1/22 · Best Answer. Copy. The jaws of a vice used in metal working have small teeth like segments cut into them to assit in gripping metal. If you use the vice for soft metals such as

Learn MoreHP500 THRUST BRNG LOW | mention the purpose of jaw plates

china hp crusher india china hp 500 cone crusher. Varahi Industries. China HP Series Cone Crusher Cast Steel Parts Socket/Thrust Bering, Find details about China Mantle, Cone Crusher

Learn MoreJaw Plates - HCE PARTS

Movable jaw plate of jaw crusher is also called jaw head or jaw back. And jaw plate is also called tooth plate,a vital resistant part of jaw crusher. A set of jaw plates usually are composed of movable jaw plate and fixed jaw plate.According to different models of jaw crushers, jaw plates also have the consistent sizes and models. In general

Learn MoreJaw reconstruction with fixation plates] - PubMed

The use of internal fixation plates in the reconstruction of mandibular continuity following serious injury, or resection of mouth floor tumours, is described. When complicated fractures are involved, the combined employment of osteosynthesis with steel wires and fixation plates is advised. Three il

Learn MoreQJ341 Mobile Jaw Crusher

Easy access to the engine compartment and in-built automatic central lubrication system reduces maintenance time, and with wear resistant liner plates fitted as

Learn MoreDo I need to remove the fixation plates after corrective jaw surgery?

5/9 · Late removal of the plates often requires a fair bit of bone removal to expose the plates. Screws may not be retrievable at all without extensive drilling of the bone. In general, fixation plates that do not become exposed do no require removal after orthognathic surgery. However, if removal is desired by the patient, it should be done after

Learn MoreJaw Plate, Teeth Plates, Jaw Crusher Wear Parts for Sale

Jaw Plate – Jaw Crusher Wear Parts. Jaw Plate is the main wear part of Jaw Crusher, including fixed plate and jaw plate . We can produce a variety of meet the requirements of the jaw plate according to the customer’s model . Because of the use of manganese content of 13% to 30% of the high manganese steel and ultra-high manganese steel, and

Learn MoreA REVIEW - African Journals Online

improved upon by increasing the eccentricity of the eccentric shaft, use of reversible jaws, bush bearing and easily adjustable toggle plate.

Learn Morejaw | anatomy | Britannica

jaw, either of a pair of bones that form the framework of the mouth of vertebrate animals, usually containing teeth and including a movable lower jaw (mandible) and fixed upper jaw (maxilla). Jaws function by moving in opposition to each other and are used for biting, chewing, and the handling of food. The mandible consists of a horizontal arch, which holds the teeth and

Learn MoreCast Manganese / Chrome Steel Jaw Plates - Gilson Co

Cast Manganese/Chrome Jaw Plates are an additional option for use in the LC-44 10in Jaw Crusher for crushing hard and tough materials. They are made of abrasion

Learn MoreMANTLE A M1 H28800 | mention the purpose of jaw plates

3054 Jaw Crusher; 2036 Feeder Screen Jaw Plant; CJ612 4448 Jaw Crusher; Screen Jaw Combo; Cone Crushers. CH660 Hydrocone; CH550 Hydrocone; CH540 Hydrocone; CH440 Hydrocone; CH430 Hydrocone; CS660 Gyrocone; CS550 Gyrocone; CS440 Gyrocone; Closed Circuit Crushing Plant; CH430 Self-contained cone;

Learn MoreThe Right Jaw Plates for the Jaw Crushers and Its Purpose

The Jaw plates are designed pieces of steel that can be found inside the Jaw crushers. It can help crush heavy materials easily.

Learn MoreLT1315 SLIDE 50 mention the purpose of jaw plates

The price of containers has gone up to ,000 USD/20GP, so we had to load 27.5 tons of parts in one container, damn shipping costs! 10-314-386-000. CHEEK PLATE, UPPER XT610. 10315463000. Memory foam earbuds fo 300 hp electric motor price mp800 mantle short head STAT/SWING JAW PLT MID HD M1 1511 hp4

Learn MoreWhat Are the Functions of Toggle Plate of Jaw Crusher ... - Zoneding

Toggle plate is the most simple and low-cost part of Jaw Crusher, which is usually made by cast iron. It is the driving part of jaw crusher and has three main functions. That is, transmit power, adjust discharge opening and function as a safety device. Transmit power, Toggle plate is a power transmission part of jaw crusher.

Learn Moremodel 2436 jaw crusher pioneer parts mercedes c-class specifications

Name Provider Purpose Expiry Type; _ok: Olark: Identifies the visitor across devices and visits, in order to optimize the chat-box function on the website. Session: HTTP: CookieConsent: Cookiebot: Stores the user's cookie consent state for the current domain: 1 year: HTTP: olfsk: Olark: This cookie is necessary for the login function on the

Learn MoreC160 SUPPORT C160 mention the purpose of jaw plates

KODAK EASYSHARE C160/C180 Digital Camera. KODAK EASYSHARE C160/C180 Digital Camera Extended user guide www.kodak.com For interactive tutorials: www.kodak.com/go/howto

Learn MoreHow to get the most wear life out of your rotatable one-piece

Fixed jaw plate – use until wear of about 30% occurs in the lower area and make the first turn. Make the second turn when wear from 90% to 100%

Learn MoreWhat is a Jaw Crusher? – MEKA Crushing Equipment

The pitman is supported by a toggle plate at the bottom of the moveable jaw. Toggle plate compressed between moveable jaw and main body. This mechanism ensures

Learn More