- [email protected]

- +86-21-63353309

gyratory crusher maintenance

gyratory crusher maintenance

HOPPER CLEANING OF GYRATORY

9/1/2022 · HOPPER CLEANING OF GYRATORY CONE CRUSHER FOR SCHEDULED MAINTENANCE OF RING SEALINGPlease

Learn MoreGyratory Crusher Services I Service - thyssenkrupp Mining Technologies

Stop your crusher, start the disassembling Replace the installed shells by preassembled spare shells Assemble the crusher - go back in operation Your added value Increased availability Increased safety Decreased labor Shortage of downtime by up to 50 %

Learn MoreGyratory crushers - thyssenkrupp

They are designed for high performance and, at the same time, cost-effective operation,. i.e. low servicing and maintenance costs. When it comes to crushing

Learn MoreHeavy duty, maintenance-friendly Gyratory Crusher

High-power crushing and easy maintenance with the Gyratory Crusher NT Get the best features of the previous model with added safety and usability functions.

Learn More2. GYRATORY CRUSHERS - Metallurgist & Mineral Processing

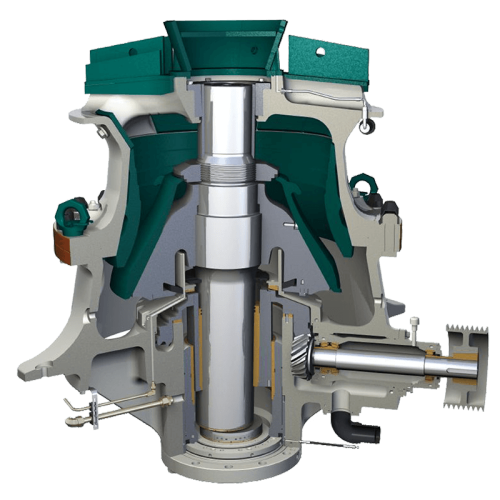

The parameters used in the basic design of a gyratory crusher are nip angle, feed rate, feed opening, closed-side setting, work index, and horsepower. The combination of the nip angle, feed opening, and closed-side setting determine the length of the crushing chamber and indirectly the length of the main shaft.

Learn MoreConstruction, Working and Maintenance of Crushers for

As compared to the jaw crusher, where it only crushes when the swing jaw moves towards the fixed jaw, with its rotational action, the gyratory crusher is always

Learn MoreGyratory Crushers TC, NT and TS model crushers

the basic concept behind adjust to temperature fluctua- crushing operations because of the gyratory crusher remains tions and wear, requiring minimal large capacity reservoirs and high the same as it did during its in- maintenance. oil flow rates to eccentric and ception, but the machine is • mainshaftassembly: the shaft bushings. entirely

Learn MoreGyratory crusher upgrades - Outotec

Go from MK I to MK nXt with our Superior primary gyratory crushers upgrades. Mix and match to suit your goals: better production, reliability & maintenance.

Learn Mores new Digital-Enabled TSUV Gyratory Crusher

The unique top-service design prioritises safety, easy maintenance and efficient crushing performance. Unlike other gyratory crushers, which

Learn MoreGyratory Crusher Services I Service - thyssenkrupp Mining

Stop your crusher, start the disassembling Replace the installed shells by preassembled spare shells Assemble the crusher – go back in operation Your added value Increased availability

Learn MoreConstruction Working and Maintenance of Crushers for

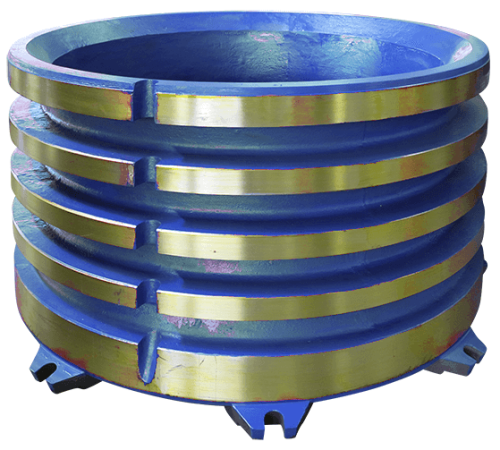

Gyratory crushers are designated by two numbers. These are the size of the feed opening (in inches) and the diameter of the mantle at its base (in inches). The feed material should be at

Learn Moregyracone crusher performance

May 20 nbsp 0183 32 Jaques range of crushers perform all manner of duties ensuring dependable and consistent performance From primary jaw crushers to Jaques Gyracone Crushers Benefits amp Features Low maintenance heavy duty design provides a long trouble free life jaques crushers australia - Mineral Processing Plant

Learn MoreJanitorial Crew Member Job Hillsboro Oregon USA,Maintenance/Cleaning

Janitorial Crew Member. Job in Hillsboro - Washington County - OR Oregon - USA , 97124. Company: Kellermeyer Bergensons Services. Full Time position. Listed on 2022-09-16. Job specializations: Maintenance/Cleaning. Cleaning Services, Facility Maintenance, Janitor, Floor Tech/Cleaning.

Learn MoreJaw crusher maintenance - Pit & Quarry

Check jaw dies daily, making sure bolts are kept tight. Check cheek plates for any excessive wear that may affect the mainframe of the jaw.

Learn MoreRegular crusher maintenance integral to reliability

Jones advises: “Always ensure the wear parts are fastened into the machine properly. With jaw crushers, if you allow the jaw dies to move during

Learn MorePDF Construction Working and Maintenance of Crushers for Crushing Bulk ...PDF

Gyratory crushers are designated by two numbers. These are the size of the feed opening (in inches) and the diameter of the mantle at its base (in inches). The feed material should be at least 15 to 20% smaller than the width of the feed opening. Gyratory crusher's discharge setting is referred to as the Open Side Setting (OSS).

Learn MoreReliability centered maintenance of cone crusher: a case study

PDF | A cone crusher is used for crushing rock. The vast majority of these installations are found in mineral processing plants.

Learn MoreTLC for Primary Crushers | E & MJ

A gyratory crusher is a significant investment for any mine. Poor maintenance can result in unplanned shutdowns for repairs, premature failures and

Learn Morefuctions of gyratory crusher

the functions of a gyratory crusher. The Gyratory Crusher TS is distinguished from other gyratory crushers by its revolutionary design which allows you to easily and safely perform major service and maintenance functions It is designed so that you can easily access and remove the eccentric assembly bushings and hydraulic piston.

Learn MoreHigh-Efficiency Cone Crusher ZI Cone Crusher | ANSWERS

Originally, the MSI technology was developed to maintain high performance crushing. However, it was found through repeated crushing tests that

Learn MoreGyratory Crusher Failure Modes | AMP Maintenance Forums

Anyway, I was wondering if anyone can assist with failure modes of Gyratory Crushers. The model we have on site is a KB 63 - 89.

Learn More