- [email protected]

- +86-21-63353309

single toggle jaw crusher working principle

single toggle jaw crusher working principle

The Working Principle Of A Jaw Crusher - Editors Top - Pinterest

The Working Principle Of A Jaw Crusher - Editors Top · There are different jaw crushers on the market, but all of them are designed and are consisted of fixed

Learn MorePart 02 - Jaw Crusher

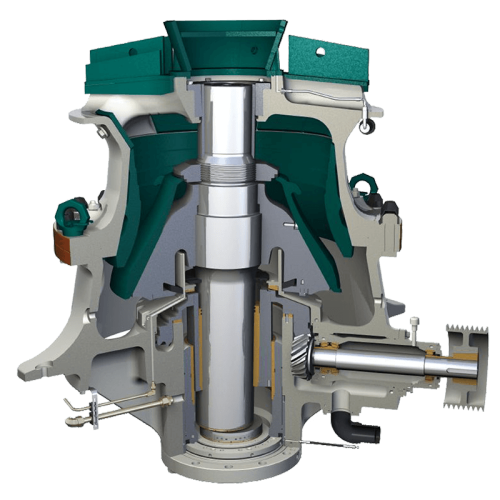

In double-toggle jaw crushers, the pitman is mounted on a fixed non-eccentric shaft situated at the top of the crusher. There are two toggle

Learn MoreMild Steel Single Toggle Jaw Crusher, for Coal - IndiaMART

Working Principle: - Now, single jaw crushers include one toggle, that goes from the bottom of the swinging jaw right up to a certain point behind the jaw

Learn MoreSingle Toggle Jaw Crusher With Unique Benefits

The working principle of single toggle jaw crusher is that the generator drives the eccentric shaft to rotate through the belt and pulley, and the swing jaw

Learn MorePDF) Selected design issues of toggle plate selection on the

For this purpose, information about kinematic analysis jaw movements was provided on the example of a single toggle jaw crusher.

Learn MoreSingle Toggle Jaw Crusher Working Principle

Single-toggle jaw crushers – design and operating principle Technical data Single-toggle jaw crusher Design Single-toggle jaw crushers are characterized by the swing jaw being

Learn MoreJaw Crusher - Conmix Crusher

Single Toggle Jaw Crusher s® are uses only one toggle plate in its mechanism. Two bearings are fit in the swing jaw of this Crusher and the other two bearings support the eccentric shaft, which is driven by the drive flywheel. An extra (non-drive) flywheel is provided to lessen the power requirement of the prime mover (motor or engine).

Learn Morevencrusher's blog: working principle of single toggle jaw crusher

Single toggle jaw crusher will be observedthat the motion is really a "rocking" one. Once the swing jaw isbooming, it's opening, at the very top, throughout the very first 1 / 2 of thestroke, and closing throughout the other half, whereas the foot of the jaw isclosing throughout the whole up-stroke.

Learn Moresingle toggle jaw crusher working principle crusher spares and head

A double toggle jaw crusher is much larger, heavier, more moving parts and lower throughput than modern single toggle jaw crushers. The lower throughput statement is a bit misleading because it's partially attributed to the type of bearings The Working Principle Of A Jaw Crusher. The working principle of the jaw crushers is very simple.

Learn MoreJaw crusher - SlideShare

3. • Working Principle Of A Crusher • A crusher uses compressive force for breaking of particle. • This mechanical pressure is achieved by the

Learn Moreen/jaw crusher how work.md at main · /en - GitHub

A jaw or toggle crusher consists of a set of vertical jaws,one jaw is kept stationary and is called a fixed jaw while the other jaw called a swing jaw,moves

Learn MoreAnalysis of the Single Toggle Jaw Crusher Force ... - Hindawi

In the cycle of motion of the single toggle jaw crusher mechanism, two phases, known as the toggle phases, are of particular interest. In each of the toggle

Learn MoreDifference Between Single & Double Toggle Jaw Crusher

A double toggle jaw crusher is much larger, heavier, more moving parts and lower throughput than modern single toggle jaw crushers.

Learn Moresingle toggle jaw crusher working principle

英语网站资料. Contribute to /en development by creating an account on GitHub.

Learn Moreworking principle of the jaw crusher

Working principle of jaw crusher The jaw crusher drives the belt and pulley through the motor, and the eccentric shaft makes the movable jaw move up and down. When the movable jaw rises, the angle between the toggle plate and the movable jaw becomes larger, thereby pushing the movable jaw plate and the fixed jaw plate to approach.

Learn Moresingle toggle jaw crusher working principle | GP100S CONCAVE UPPER M

Range, Working Principle, Appliion. Jaw Crusher Working Principle A sectional view of the single-toggle type of jaw In one respect, the working principle and appliion of this machine is similar to the . in the working of every 2.13 Block Flow Diagram showing various. Pe 400 By 600 Single Toggle Jaw Crusher Specifications

Learn Moresingle toggle jaw crusher working principle main copper-alloy

single toggle jaw crusher working principle crusher wear countershaft bushing blow bars single toggle jaw crushers for mining - single toggle jaw crushers for mining. Double wedge adjusting device, Elastic limit damping device. Mar 12, Singletoggle jaw crushers are ideal for maximum throughput rates when crushing mediumhard and hard

Learn MoreA REVIEW - African Journals Online

A review on the design and operations challenges of a single toggle jaw crusher is presented. Strength and fracture toughness of the material to be crushed

Learn Moresingle toggle jaw crusher working principle | Z294 RING TOE

Jaw Crusher Principle, Diagram, Construction, Working. Jaw crusher working principle a sectional view of the single-toggle type of jaw crusher is shown below in one respect, the working principle and application of this machine is similar to the dodge crushers the movable jaw has its maximum movement at . jaw crushers working principle | Double

Learn Moresingle toggle jaw crusher working principle | hp 400 cone crusher

In the single toggle jaw crusher, an eccentric shaft is installed on the top of the crusher. Shaft rotation causes, along with the toggle plate, a compressive action of the moving jaw. A double toggle crusher has, basically, two shafts and two toggle plates. The Working Principle Of A Jaw Crusher. The working principle of the jaw crushers is

Learn Moredouble toggle jaw crusher machine

A sectional view of the single-toggle type of jaw crusher is shown below. In one respect, the working principle and application of this machine are similar

Learn More