- [email protected]

- +86-21-63353309

lip seal design guide

lip seal design guide

PDF Design Guide PTFE Lip Seal - promo.parker.comPDF

The PTFE Lip Seal Design Guide is your premier PTFE seal selection guide for hardware design, seal configuration and material specification options for a wide range of standard and complex applications. FlexiSeal The FlexiSeal is a spring-energized U-cup utilizing a variety of jacket profiles, spring types and materials in Rod & Piston, Face

Learn MoreOil Seal Material Design Guide | OneMonroe

Nitrile Buna-N 70 durometer compound is the standard material for our seals and is recommended for a majority of common applications. Nitrile lip seals work

Learn MorePDF PTFE Lip Seal Design Guide - repurvis.comPDF

In fact, this PTFE Lip Seal Design Guide exists separately from other Parker EPS market-specific publications precisely because virtually every industry has specific needs for the unique physical and chemical properties of these remarkable seals.

Learn MorePDF PTFE Lip Seal Design GuidePDF

In fact, this PTFE Lip Seal Design Guide exists separately from other Parker EPS market-specific publications precisely because virtually every industry has specific needs for the unique physical and chemical properties of these remarkable seals.

Learn MorePTFE Lip Seal Design Guide — EPS 534 | Zatkoff

The PTFE Lip Seal Design Guide is your premier PTFE seal selection guide for hardware design, seal configuration and material specification

Learn MoreOIL SEAL & O-RINGS

lip design. Koyo oil seals employ a linear-contact lip, which pro- vides proper radial lip load. The lip design ensures excellent sealing performance

Learn MorePTFE Lip Seal Design Guide

3 rows · The PTFE Lip Seal Design Guide is your premier PTFE seal selection guide for hardware

Learn MorePTFE Lip Seal Design Guide

In fact, this PTFE Lip Seal Design Guide exists separately from other Parker EPS market-specific publications precisely because virtually every industry has specific needs for the unique physical and chemical properties of these remarkable seals.

Learn MoreA new radial lip seal design approach - Pure

8 Sealing Lip. 9 Rod Guide. 10 Rod Guide PI'FE. 11 Oil Chamber. 4-- Oil flow direction. Oil film thickness. Figure 3 Definition of instroke

Learn MorePDF Fluid Power Seal Design Guide - Parker HannifinPDF

Parker recommends the use of the Type B PolyPak (BPP Profile) for rod seal applications due to its design features, including: • Excellent film-breaking capability of the beveled lip design • The higher level of lip loading provided by the Type B offers maximum sealability • The long body of the design provides maximum stability

Learn MoreHIGH PERFORMANCE SEALS - AFT Fluorotec

Length (thickness) can be to BS or ASTM standards or specified to suit any Can be integrated into a seal design or they can be specially shaped

Learn MorePTFE Seals - Parjet

This design manual is intended as a guide. elastomeric lip seals . ing out the sealing lips, creating a tight seal against the groove.

Learn MoreFluid Power Seal Design Guide - Valley Seal

Type B PolyPak. A rectangular shaped symmetrical squeeze seal with a knife trimmed beveled lip. Standard materials include 4615, 4622, 4651, 4263, 4207, 4266. 6-10 5. A dual lip seal created by the combination of a standard PolyPak square shell and a rubber lip seal/energizer. Standard materials are a 4615 shell and 4180 lip seal/energizer.

Learn MoreShaft Seal - RL Hudson

R.L. HUDSON & COMPANY | SHAFT SEAL DESIGN & MATERIALS GUIDE. Over two decades ago, RL Hudson began with a Axial Dirt Lip Seals .

Learn MoreLip Seal Design Guide - What You Need To Know About Dynamic Seal

Nov 30, · Ptfe lip seal design guide. Rubber fiber outer case and an elastomeric seal lip. Radial oil seals, also known as rotary shaft lip seals, are round sealing devices used to. Flexilip, flexicase and flexiseal rotary profiles. Radial lip seal, allowing severe leakage and leading to. Of national and international standards and guidelines listed in

Learn MoreOil Seal Design & Selection | GBSA, Inc

Comparing Lip Designs · Maximum shaft motion is linear velocity of 200 ft./min. (1M/sec.) · Maximum pressure capability is 4 psi (.28Kg/cm²). · Stroke length

Learn MoreRotary Seal Design Guide - [PDF Document

The Clipper design features an integrally moldedrubber fiber outer case and an elastomeric seal lip. Theunique, nonmetallic construction

Learn MoreSealing lip design | SKF

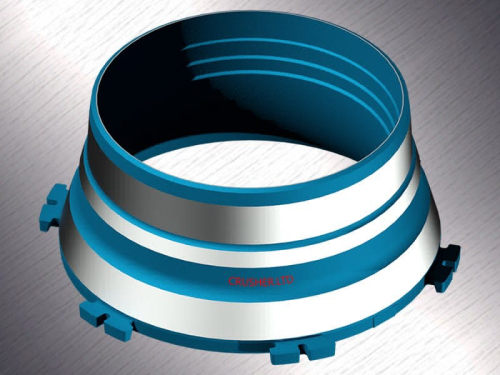

Sealing lip design. The form and design of a sealing lip is based on knowledge gained through research and development activities as well as wide practical experience obtained by SKF in

Learn MoreSelection of seal design and material - SKF

Radial shaft seals that are primarily used for contaminant exclusion should be installed with the lip pointing outward. When additional protection is needed,

Learn MoreCatalog EPS 5370, Fluid Power Seal Design Guide - Austin Seal

Type B PolyPak. A rectangular shaped symmetrical squeeze seal with a knife trimmed beveled lip. Standard materials include 4615, 4622, 4651, 4263, 4207, 4266. 6-10 SL A dual lip seal created by the combination of a standard PolyPak square shell and a rubber lip seal/energizer. Standard materials are a 4615 shell and 4180 lip seal/energizer.

Learn MorePTFE Lip Seal Design Guide - Macroseal

5 rows · The PTFE Lip Seal Design Guide is your premier PTFE seal selection guide for hardware

Learn More