- [email protected]

- +86-21-63353309

part of jaw crusher

part of jaw crusher

Components of Jaw Crushers - Dezhou Qunfeng Machinery Manufacturing Group

The working part of a jaw crusher is two jaws. One is the fixed jaw plate (fixed jaw), which is fixed vertically (or slightly inclined at the upper end) to the front wall of the machine. The other is the movable jaw plate (movable jaw), which is inclined and forms a large crushing chamber (working chamber) with the fixed jaw plate.

Learn MoreJaw Crusher Explained - saVRee

Jaw Crusher Components · Fixed Jaw · Moving Jaw · Jaw Liners · Main Shaft (Pitman Assembly) · Drive Pulley & Flywheel · Toggle Plate(s) & Tension Rods/Assembly.

Learn MoreSammy Ji on : #JawPlateToothplate #sandvikcrusherjawplate

Report this post #JawPlateToothplate #sandvikcrusherjawplate #fixjawplate #factorymanufacturer #constructionmachinery Jaw crusher parts, high manganese steel material, wear-resistant longer.

Learn MoreSUN ALLOYS - Crusher Parts Manufacturer

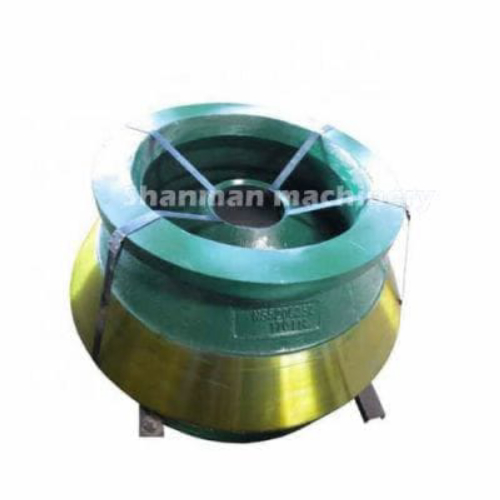

INTRODUCTION. We Take This Opportunity to introduce ourselves as the leading manufacturer of Jaw-Plates, Cone-mantle, Rollers, and all other Crusher parts, equivalant to national and international standards. We are a part of the crushing industry since 2010. We started with our 1st unit (Sun Alloys) with a casting capacity of 50 tons.

Learn MoreJaw Crusher - an overview | ScienceDirect Topics

Jaw Crusher. The capacity of jaw crushers is a measure of the mass or volume of crushed material produced in unit time of operation. From: Mineral

Learn MoreCharacteristics and Comparison of Four Types of Jaw Crushers

An eccentric shaft is positioned on the top of the crusher. The swing jaw plate hangs on the eccentric drive shaft and moves up and down in elliptical motion, which compresses rock material as it moves down from the feeding part. Double toggle jaw crusher Also, swing jaw is hinged at the top, and this support point is hand shift.

Learn MoreJaw Crusher Wear Parts - Columbia Steel Casting Co., Inc

The right jaw design can make a big difference for your jaw crusher. · Straight, full curved, and straight with curved ends jaws · Smooth and toothed jaws · High-

Learn MoreParts of a Crusher: Jaw Crusher - Colorado Used Cat Equipment

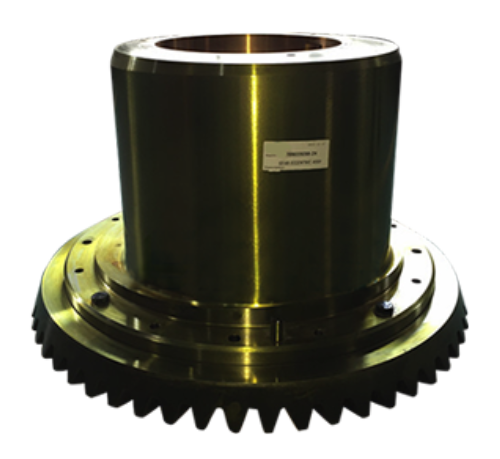

The moveable jaw is attached to the eccentric shaft and is where the energy is generated. Also called the pitman, the eccentric shaft is rotated

Learn MoreJAW CRUSHER WEAR PARTS - Precision Casting

Jaw Crushers are mainly used as primary crushers and secondary crushers in mining, construction materials, infrastructure and other sectors. As a popular crusher, the main working parts of the jaw crusher are two jaw plates. One is called the fixed jaw (stationary jaw), which is fixed vertically on the front wall of the machine frame.

Learn MoreJaw Crusher Parts - Casteel Foundry

the common repalcement wear parts of jaw crusher is jaw plates, side plate /cheek plates, jaw wedges, toogle plate, toogle bearing and toogle seat, the jaw plates consist with fixed jaw tooth and swing jaw tooth which the fixed jaw is wearing bit faster then the swin jaw ,and cheek plates having the left and right, upper and lower which the lower

Learn Morejaw crusher spare parts - IndiaMART

We Supply Spare Parts & Wear Parts of Jaw Crusher i.e.Jaw plate moving, Jaw plate fix, Side Liners, Cheek Plates, Upper & Lower Wedges, Wedge bolts,

Learn MoreJaw Crusher Parts & Jaw Crusher Spares | CMS Cepcor

CMS Cepcor® manufactures and supplies the best in jaw crusher replacement parts worldwide. We provide a range of mechanical spare parts which is unmatched. +1-877-CEPCOR1 (+1-877-2372671) 9:29 pm CST +1-877-CEPCOR1 (+1-877-2372671) Visit us at Bauma 2022, Munich, Germany 24th-30th October

Learn MoreJaw Crusher Spare & Wear Parts - Precision Crushers & Spares

Precision Crushers & Spares is a manufacturer and supplier of jaw crusher spare & wear parts such as jaw plate, fixed jaw plate, cheek plate & toggle plate etc. Tel: +971 (0)9 228 2209 Fax: +971 (0)9 228 2210

Learn MoreWhat Are Jaw Crusher Parts? - Sandrock Mining

The pitman is the main moving part in a jaw crusher, which forms the moving side of the jaw. A jaw crusher pitman has two supporting points for supporting it in the body of the

Learn MoreThe Wear Parts of Jaw Crusher - Luoyang Dahua

For the jaw crusher, its wearing parts mainly include movable jaw plate, fixed jaw plate, lining plate, toggle plate, eccentric shaft and bearing.

Learn MoreJaw Crusher Components & Parts - Mineral Processing & Metallurgy

Although the jaws do the work, the real heart of the jaw crusher and its components are the toggle plates, the pitman, and the ply wheel. These are the parts and components that generate the crushing action and provide the energy needed to break the ore. Let's follow the chain of events within a crushing cycle to see how they all go together.

Learn MoreJaw Crushers - Astec

Jaw Crushers Jaw Crushers Available in a variety of sizes and configurations, the Hydra-Jaw® crusher, Pioneer® jaw crusher and Iron Giant jaw crushers deliver high-capacity crushing and reliable performance for increased operational productivity and profitability.

Learn MoreJaw Crusher Wear Parts - Unicast Inc

Jaw Plates; Cheek Plates; Wedges; Toggles; Toggle Seats. Unicast proprietary alloys and innovative designs result in long wear life compared to other OEM

Learn Moresvedala crusher parts | supplier part ball mill

Allis Chalmers Svedala Hydrocone Crusher parts. Used svedala jaw crusher in sweden crushers 1998 sweden, rby. poa. svedala 530 crusher type: cone crusher, transport dimensions 2.8 3.1 2.5 jaw crusher part rock crusher wear thrust plate hp3 part bowl liner crusher eccentric bushing suppliers sa cone crushers

Learn MoreJaw Crusher Parts Catalog - Zhejiang Gravik Machinery and Equipment Co

The jaw crusher is a crushing machine that uses the squeezing and bending action of the two jaw plates to crush materials with various hardness. The crushing mechanism is composed of a fixed jaw plate and a movable jaw plate. When the two jaw plates are close, the material is crushed.

Learn MoreThe Most Practical Jaw Crusher Repair and Maintenance Manual

The lubrication of the interface between the parts of the jaw crusher is very important. It can minimize the friction generated during the operation, make the whole jaw crusher run smoothly, and extend its service life. Unlike gyratory crushers, the main lubrication used in jaw crushers is grease instead of oil. When using grease, there may be

Learn More